Do you know if your frontline workers are doing their job correctly, and safely every time?

If not, this is why you need to use field tickets.

Field tickets are essential documents used by manufacturing facilities to record and track work orders, inventory, materials, and other critical information.

If you create an efficient field ticket, you boost your manufacturing efficiency.

At FAT FINGER, we aim to provide frontline workers with easy, fast, and flexible digital procedures, driving operational excellence.

That’s why we will explore the following:

- The components of a field ticket

- How field tickets streamline your daily operations

- How FAT FINGER can help you create and manage field tickets

Ultimately, by identifying key components that make up an effective field ticket, we will provide guidelines for creating a field ticket checklist customized to the facility’s unique needs.

1 – Components of an Effective Field Ticket

A field ticket functions as a receipt when manufacturers make on-site visits. The ticket is supposed to help them keep track of everyday operations and product transfers.

It plays a crucial role in the supply chain because it documents transactions and helps vendors and manufacturers keep track of delivered products and services.

An effective field ticket, paper-based or not, is supposed to have at least these seven items:

- Work order number. This is a unique identifier that helps track the work order associated with the field ticket.

- Date and time. Note the date and time in the field ticket when the work was performed.

- Description of work. Provide a brief description of the work performed, including any materials used, equipment utilized, and any issues encountered.

- Labor hours. Record on the field ticket the number of hours spent on the job.

- Equipment used. Note the type, model, and serial number of the equipment used.

- Material used. This includes the type, quantity, and any pertinent serial or lot numbers. Record them on the field ticket.

- Signature. The first and most important signature on the field ticket is that of the technician or engineer performing the task. They verify the accuracy of the results obtained in the task.

- Customer signature. When applicable, the customer must sign the field ticket to indicate that the work was completed to their satisfaction.

- Additional comments. Indicate any additional observation related to the work performed on the field ticket.

These components provide a detailed record of the work performed.

However, recording these details is the easy part of field ticketing. Keeping track of the tickets and storing them is what determines a manufacturer’s efficiency optimization.

Paper-based field tickets make it hard for manufacturers to manage their vast amount of data. This is because paper-based field tickets are commonly prone to issues.

Common Paper-Based Field Ticket Issues

Using paper-based field tickets involves eyeballing Excel spreadsheets to interpret field-related data, and reconciling it with the data on field tickets by hand.

As if that’s not enough, the process is made more difficult by other common issues that come with using paper-based field tickets.

They include:

- Lost or misplaced field tickets. This results in a lack of documentation for work performed, which can lead to disputes over billing and payment. This can cause delays in payment and create inefficiencies in the invoicing process.

Additionally, lost or misplaced field tickets can make it difficult to track progress on a job site, leading to delays in completion and increased costs.

- Illegible handwriting. If the information on a ticket is difficult to read, it can lead to mistakes and errors in billing and tracking work performed. This results in delayed payments as well as increased costs due to rework and corrections that need to be made.

When managers find it difficult to analyze data and make informed decisions about the future because of illegible handwriting, workforce productivity and profitability of the manufacturing facility company reduce.

- Incomplete information. Incomplete information in manufacturing facilities’ field tickets can also negatively affect their efficiency, productivity, and profitability.

Information such as the type of work performed, the equipment used, or the number of hours worked can make it hard to track progress on a job site. Consequently leading to delays in completion and increased cost.

At FAT FINGER, we are aware of these issues.

This is why we recommend adopting FAT FINGER’s machine learning digital procedures to create your field ticket.

With our electronic field ticket platform, all field tickets are recorded and stored digitally, eliminating the risk of losing or misplacing them.

Our platform also allows for easy input and access to information, reducing the likelihood of illegible handwriting and incomplete data.

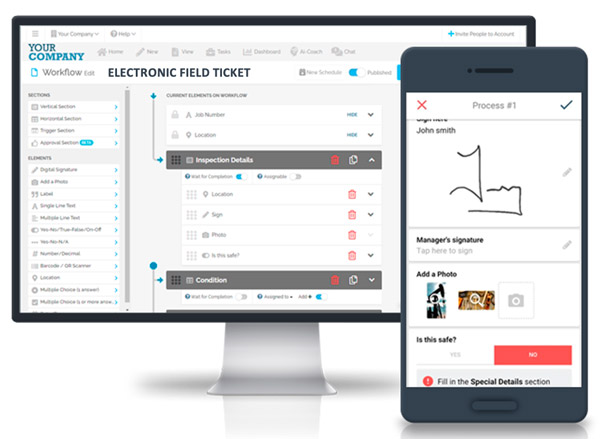

We provide a no-code builder to enable frontline workers to create a customized field ticket.

Creating a Customized Field Ticket Checklist

Creating a customized field ticket checklist guarantees that the field ticket will meet the specific needs of your manufacturing facility.

FAT FINGER’s no-code builder enables frontline workers’ mobile app development, fulfilling their field ticket checklist.

Here’s how you can do it. You follow these three steps:

- Identify the information that needs to be captured on the field ticket. This information may vary depending on the workflow, the type of work performed, and the equipment used.

- Determine the format of the field ticket. Even though paper-based tickets have been used for a long time, we recommend adopting electronic field tickets. They offer real-time data collection for real-time decision-making, improving workflow management.

It is also important to involve the frontline workers who will be completing the field tickets in the digital procedures. They can recommend efficient standard operating procedures, helping ensure that the checklist is effective and user-friendly.

- Test the field ticket checklist. Do this before implementation to identify any issues or areas for improvement. Once the checklist has been refined and customized to meet the needs of your manufacturing facility, ensure that all workers are trained on how to use it effectively.

When field ticket services become more integrated into your digital workflow management, your operations management becomes more streamlined.

The video below shows you the digital procedures of customizing an electronic field ticket with FAT FINGER.

Create your electronic field ticket today to streamline your daily operations.

2 – Streamlining Daily Operations With Electronic Field Tickets

Manufacturing facilities need to evolve with the advent of technology. This can be done by adopting technologies that increase productivity and reduce costs.

Implementing electronic field tickets can be an effective tool for optimizing efficiency and operations management.

However, it is important to have a clear plan for implementing the field tickets, to ensure that they are effectively integrated into daily operations.

Here are some strategies to consider when implementing the field ticket:

- Develop a Clear Process. Before implementing field tickets, it is important to have a clear process in place for how they will be used.

This includes identifying who will be responsible for completing and reviewing the ticket, as well as the frequency and timing of their use.

- Provide Adequate Training. Proper training is essential to ensure that all personnel understand the purpose of the field tickets and how to use them effectively.

Consider providing hands-on training and offering support as needed to help ensure compliance and accuracy.

- Monitor Compliance. Regularly monitoring compliance with the field ticket checklist can help identify areas for improvement and ensure that all personnel are using it consistently and correctly.

Consider conducting periodic audits or spot checks to monitor compliance and provide feedback.

- Encourage Accountability. Emphasize the importance of accountability when it comes to checklist usage.

This can include recognizing personnel who consistently use the checklist effectively and holding individuals accountable for any errors or omissions.

With a clear process in place, proper training, regular monitoring of compliance, and an emphasis on accountability, you will start experiencing the benefits of shifting to electronic field tickets.

Benefits of Shifting to Electronic Field Tickets

We have already shown you the issues that come with paper-based field tickets.

Shifting to electronic field tickets eliminates those issues, and lets you enjoy the following benefits:

- Decreased days sales outstanding. Days sales outstanding (DSO) is the average number of days it takes a company to receive payment for a sale.

Manual systems and paperwork create high DSO due to their slow and unnecessary clerical processes. They also increase the chances of error. This causes the overall records, billing, and inventory levels of both parties to be affected.

By using FAT FINGER’s centralized cloud-based mobile application system, you can streamline accounting and daily field operations. Ultimately, you will decrease your DSO.

- Streamlined job-to-invoice process. Decision makers, accounting personnel, and field personnel on the ground must use an electronic field ticket to streamline their job-to-invoice process.

FAT FINGER’s mobile applications will enhance record keeping and reduce errors when invoicing and issuing job quotes. Additionally, it will prevent the dispatching of duplicate labor or unavailable equipment.

- Enhanced efficiency even in remote locations. In most cases, field workers operate in remote areas without a reliable internet connection. This is despite the fact that they need to communicate with the office.

FAT FINGER does not require an internet connection. Therefore, it allows the field crew to perform their tasks, alter their field tickets accordingly, record any necessary data, and attach documents or photos.

When they return to an area with a reliable internet connection, they sync the mobile application to transmit the information for invoicing.

- Customizable alerts to ensure everyone is updated. An alert system is integrated into FAT FINGER to allow users to create text or email notifications.

These alerts can be customized according to time, user, or purpose. The alert system is able to filter notifications according to the crew, client, office, and business segment.

This system can be used to notify all personnel of any new developments. This way, your facility improves customer service, reduces fuel costs, and improves communication among the firm’s personnel.

The best no-code builder that can develop electronic field tickets and guarantee operational excellence is FAT FINGER.

Well-Pro, an oil field service company, decided to transform their operations from the frustrating and high cost manual paper and excel systems to a digital approach with goals to reduce operational costs. They were able to cut their operating cost by $1 million.

“Using FAT FINGER allows us to reduce days outstanding, lost tickets and see our exact daily sales numbers which is a huge benefit for planning our business.” Casey Roling, VP of Operations, Well-Pro Services, L.P.

Action: Start your efficiency journey today by scheduling a demo of FAT FINGER’s electronic field ticket solution.

3 – FAT FINGER

At FAT FINGER, we understand the challenges and complexities that come with managing paper-based field tickets.

That’s why we’ve developed a cutting-edge technology solution that can help streamline this process and optimize efficiency for your facility.

By incorporating our electronic field ticket system, you eliminate the need for paper-based systems and streamline the data collection process. This significantly reduces errors and omissions, and ensures that all data is captured accurately and efficiently.

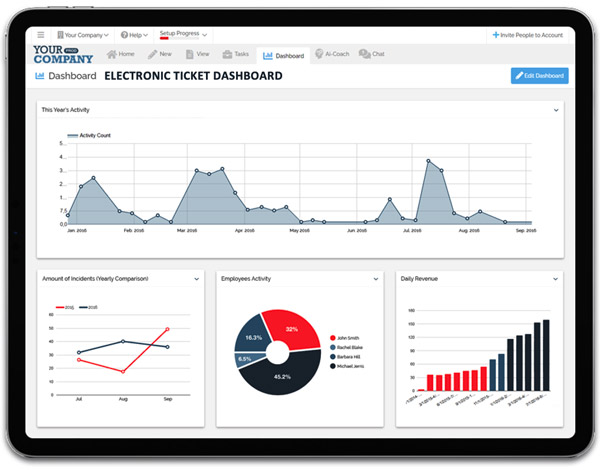

The table below shows you 10 reasons for adopting FAT FINGER’s electronic field ticket system.

It compares the traditional field ticket management system with FAT FINGER’s Electronic Field Ticket System.

| Feature | Traditional Field Ticket Management | FAT FINGER’s Electronic Field Ticket System |

| Physical Paper Tickets | Yes | No |

| Real-time Data Collection | No | Yes |

| Automatic Time-stamping | No | Yes |

| Data Entry | Manual | Digital |

| Signature Collection | Physical | Digital |

| Electronic Record-keeping | No | Yes |

| Automatic Error-checking and Correction | No | Yes |

| Real-time Collaboration | No | Yes |

| Remote Access | Limited | Yes |

| Integration with Other Systems | Limited | Yes |

With our customizable platform, you can easily create and modify digital field tickets to suit your facility’s specific needs and requirements.

As if that’s not enough, our platform offers real-time tracking and reporting capabilities, allowing you to monitor progress and identify areas for improvement in real-time. This guarantees safety compliance.

Learn More: What do you include in an incident reporting checklist? Our previous article is a comprehensive guide for safety compliance managers.

Visit our website and create your own electronic field ticket.

Our team of experts is always available to answer any questions you may have and provide guidance on how our technology can help your facility achieve its goals.

Boost Efficiency With Electronic Field Tickets

By addressing common paper-based issues and identifying key components crucial for creating effective field tickets, manufacturing facilities can utilize customized checklists to improve their daily operations.

Expert Tip: To safeguard a large manufacturing facility, you will need a risk assessment checklist. This article serves as a guide on how to ensure the safety of your workers.

Manufacturers can implement their customized checklists through clear processes in place, proper training, regular monitoring of compliance, and emphasis on accountability.

Moving forward, it is recommended that manufacturing facilities regularly review and update their field ticket checklists, ensuring they continue to meet their needs and address any new challenges that may arise.

By doing so, they will boost their manufacturing efficiency and remain competitive in the industry.

“My team is thrilled with how easy it is to use FAT FINGER – they no longer dread tedious data entry tasks and can focus on higher priority initiatives. It’s been an absolute game-changer for our company!” – Peter Smith, Business Leader

Share on LinkedIn