Learn about the basics of oil and gas safety inspections, what you need to be looking for, and how to improve your audit process.

Key takeaways:

-The oil and gas industry is highly regulated, and there are ways to improve your audit process, making it more efficient and effective.

–Various common mistakes lead to accidents or injuries in the oil and gas industry and we have identified steps to avoid them.

-Paper checklists can be cumbersome and ineffective in terms of safety audit and inspection, which is why many companies are moving towards electronic ones.

– Using FAT FINGER’s software can help oil and gas companies improve their safety programs by allowing them to manage their safety inspections from start to finish, ensuring that all aspects of safety are covered.

Table of Contents

I. Safety Audit vs Safety Inspection

II. 4 Steps in Performing Better Safety Inspection

III. Common Mistakes that Lead to Accidents or Injuries

IV. Advancement in Safety Inspections and Audits

Oil and gas production is a complex and dangerous industry. One small mistake can lead to a major accident, so these companies must take every precaution to ensure the safety of their employees and the environment.

Part of this process is regular safety audits and inspections.

Safety Audit vs. Safety Inspection

Although the words are sometimes used interchangeably, safety inspections and audits are two distinct activities with the same objective: to promote a safe workplace.

The main difference between safety audits and safety inspections is that audits are about programs and processes, while inspections are about people, places, and things. Safety audits are used to ensure that a company’s safety goals are being met, while safety inspections are used to identify risky behaviors and hazards that might lead to accidents.

4 Steps in Performing Better Safety Inspection and Audits

Audits and inspections are essential in the oil and gas industry to ensure safety and compliance. There are several ways to improve safety in the industry, but some of the most effective methods include conducting regular safety inspections, ensuring that all equipment is up to date and well-maintained, and providing comprehensive training for all employees. However, they can also be time-consuming and disruptive to operations. Here are some steps on how to perform audits and inspections more efficiently:

1. Plan ahead

Make sure you know what you need to inspect and gather all the necessary tools and resources beforehand. This will save time on the day of the audit or inspection.

2. Be organized

Create a checklist of all the items you need to inspect and tick them off as you go. This will help you keep track of your progress and avoid missing anything.

3. Communicate with stakeholders

Let stakeholders know in advance about the audit or inspection so that they can be prepared. This will minimize disruptions to operations.

4. Take action

If any problems are found during the audit or inspection, make sure to address them immediately. This will help prevent future issues.

By taking these steps, oil and gas companies can help minimize the risks inherent in their operations and create a safer working environment for everyone involved, especially for some common safety mistakes.

Common Mistakes that Lead to Accidents or Injuries

Oil and gas industry workers are often required to perform safety inspections regularly. However, there are a few common mistakes that can lead to accidents or injuries. Here are a few of the most common mistakes:

Forgetting to check for leaks

Oil and gas leaks can be extremely dangerous, and it’s important to check for them regularly. If you suspect a leak, immediately notify your supervisor so that the area can be evacuated and repaired.

Failing to properly secure equipment

Loose or unsecured equipment can fall and injure people, so it’s important to make sure that all tools and machines are properly secured before use.

Not following safety procedures

Every job has its own set of safety procedures, and it’s important to follow them carefully. Ignoring safety procedures can lead to serious accidents.

By being aware of these common mistakes, oil and gas industry workers can help to prevent accidents and injuries in the workplace. During the audit, these common mistakes that lead to accidents are identified and corrected.

Advancement in Safety Inspections and Audits

Oil and gas production involves a complex network of activities, from drilling and transportation to refining and distribution. With so many potential hazards, these companies must have robust safety programs in place. One essential component of these programs is regular safety inspections. However, traditional methods of safety inspections, such as paper checklists, can be time-consuming and error-prone.

One of the main disadvantages of using paper checklists for safety inspections is that they can be repetitive. For example, if an oil and gas company is using paper checklists for their safety audits, each auditor would need to go through the same process for each inspection. This can lead to auditors feeling like they are doing the same thing over and over again, which can lead to fatigue and carelessness.

Additionally, paper checklists are often more prone to human error than electronic ones. For example, if an auditor accidentally marks something as “Not Applicable” instead of “Applicable”, that inspection item will be missed. This could lead to a critical safety issue being overlooked. Overall, paper checklists can be cumbersome and ineffective, which is why many companies are moving towards electronic ones.

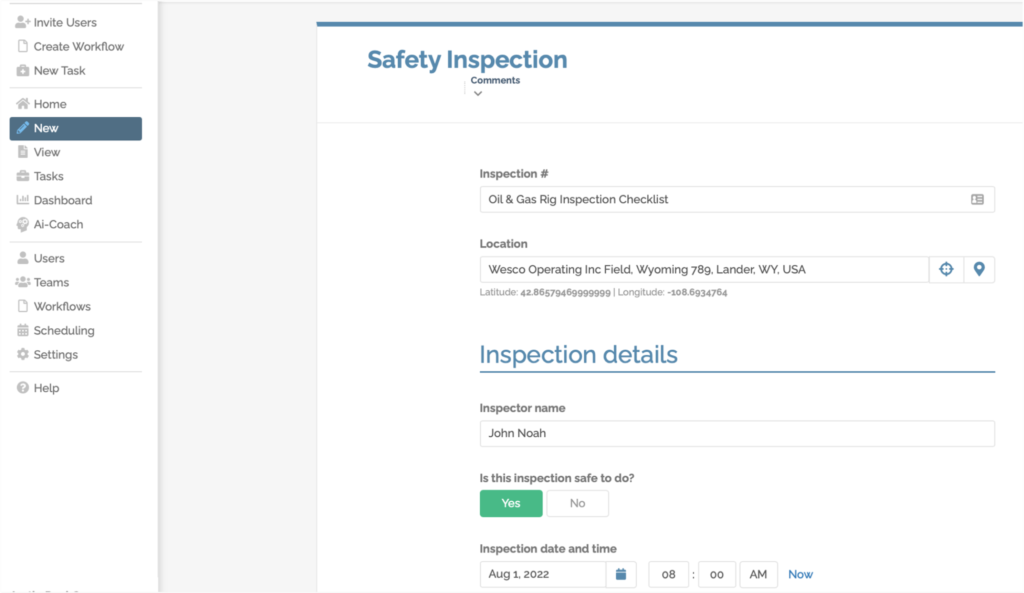

Fortunately, there are now digital solutions available that can help oil and gas companies streamline their safety inspection processes. FAT FINGER is a leading provider of safety inspection software. FAT FINGER enables companies to quickly and easily conduct comprehensive safety inspections, identify potential hazards, and track corrective actions. For oil and gas companies looking to improve their safety programs, FAT FINGER is the ideal solution.

FAT FINGER has been designed to make safety inspections easier, faster, and more accurate. It allows you to manage your safety inspections from start to finish, ensuring that all aspects of safety are covered.

With this pre-made template, you can start capturing data right away, or modify the app to meet your requirements using our Workflow builder.

For a tutorial on how FAT FINGER can help with your safety audits and inspection, see this safety inspection video.

With FAT FINGER, you can be sure that your safety inspections are always up-to-date and compliant with regulations. We make it easy for you to keep track of your progress and identify any areas that need improvement.

Various users have confirmed that using the FAT FINGER platform, they’re able to resolve workplace hazards 83% faster, 85% more people are held accountable for their actions, and 60% of workplaces have been made safer.

About FAT FINGER:

Ensure front-line teams do their work correctly every time. Drag & drop digital procedures that unlock operational excellence.

In seconds anyone can build and deploy enterprise-grade mobile applications using an easy drag-and-drop no-code builder.

FAT FINGER uses machine learning to coach app users in real-time to make safer and improved decisions.

Try building your digital procedure on FAT FINGER for free @ www.fatfinger.io