Material Inspection

Ensure the highest quality standards of your products with a digital material inspection.

Trusted by companies all over the world

Before FAT FINGER

High defects

Defects can often only be identified during a thorough inspection, which can add additional stage to the manufacturing process

Production delays

Extensive monitoring that manual inspection requires can cause delays in production which increases manufacturing cost

Achieve zero defects in no time

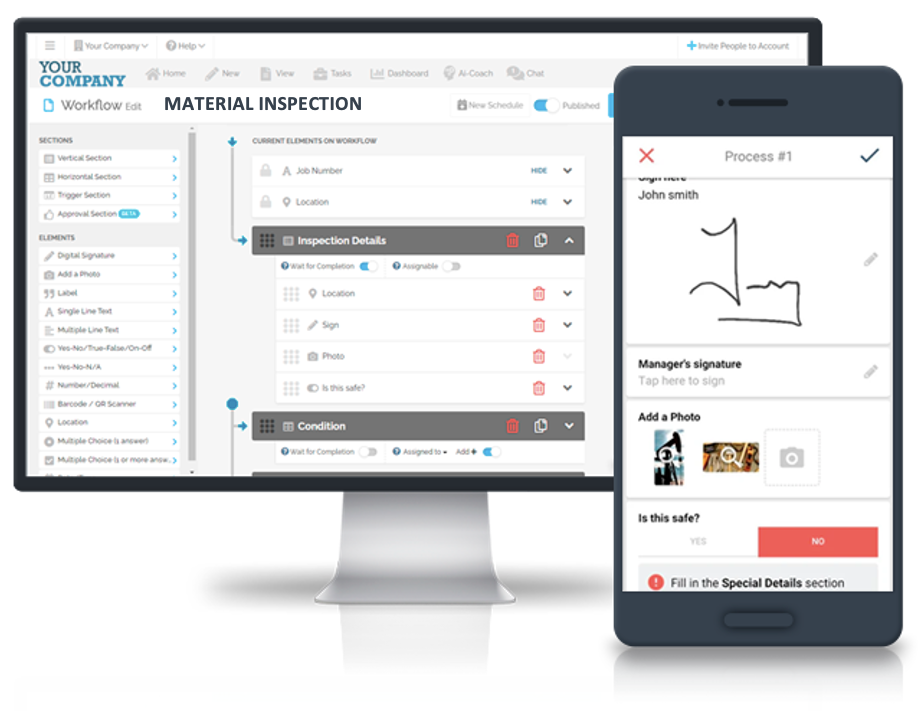

With our revolutionary workflow, materials can be inspected quickly and accurately with less reliance on manual labor. Defects can be identified early in the production process before they become too costly. Drag-and-drop digital SOPs, audit processes and inspection checklists with ease.

Ensure a smooth production with digital workflows

Say goodbye to tedious manual paperwork and reporting – it’s time for automated workflow. Keep your team in sync with just a few clicks. Cut back on wasted hours spent tediously processing, scheduling, and monitoring so you can maximize productivity.

“FAT FINGER makes it possible to instantly diagnose any issue or mistake that may be occurring in the production process. The ability to react and solve problems as soon as they surface is essential in today’s manufacturing industry.”

Mike Smith, Quality Assurance Manager

Respond faster to product issues

Get ready to take an interactive ride into the future of analytics.

Data from digital material inspections make it easy to quickly identify defects in products and take proactive measures that help reduce any risk of the defects ending up in hands of the customers. With FAT FINGER real-time dashboard, analytics has never been easier and more effective.

Do more of what matters most

Manage your operations effectively in just a click.

FAT FINGER gets you results in operations

Committed to building sustainable operational excellence platform – trusted by thousand of users across the globe.

56%

Reduced costs

97%

Feel in more control of their operations

7.28hrs

Reclaimed per procedure

84%

Improved quality of output. More data means more actionable insights!

Guide to Material Inspections

Here are few key things to keep in mind when it comes to material inspection.

1.Ensure that the material is suitable for the intended purpose.

If it’s being used in a critical application, you’ll want to ensure that it meets all of the relevant safety and quality standards.

2. Know what to look for when inspecting materials.

There are a few key indicators of material quality, such as density, surface finish, and dimensional accuracy.

3. Make sure that the material meets all of the necessary quality requirements.

This includes checking for defects, impurities, functionality, and more.

4.Consider the benefits of using the material in question.

Is it more cost-effective than other options? Is it more durable? Is it easier to work with?

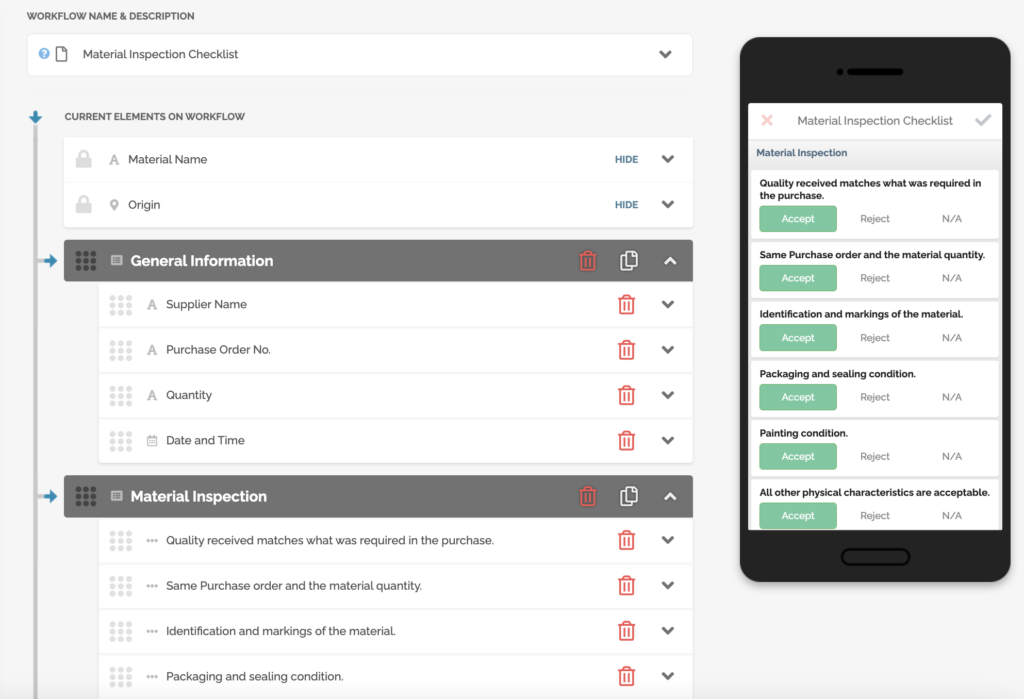

Material Inspection Tagging System

The material inspection tagging system allows inspectors to quickly and easily identify which materials meet the acceptance criteria specified in the purchase order. By assessing a material utilizing these criteria, three possible results can be indicated:

1.Acceptable

Once the material is inspected and found to meet the necessary quality standards, it can be tagged as accepted and used in manufacturing.

2.Rejected

Materials classified as “rejected” do not meet all requirements and cannot be used. Rejected materials must be appropriately tagged and removed from the manufacturing process to prevent any issues with the final product.

3.Conditional

This means that they do not meet all of the requirements but can be used if they are correctly modified or will not affect the final product quality.

The identification tagging system is a vital inspetion control tool that helps to ensure that materials meet the quality specified in the purchase order.

Inspection done right – the first time.

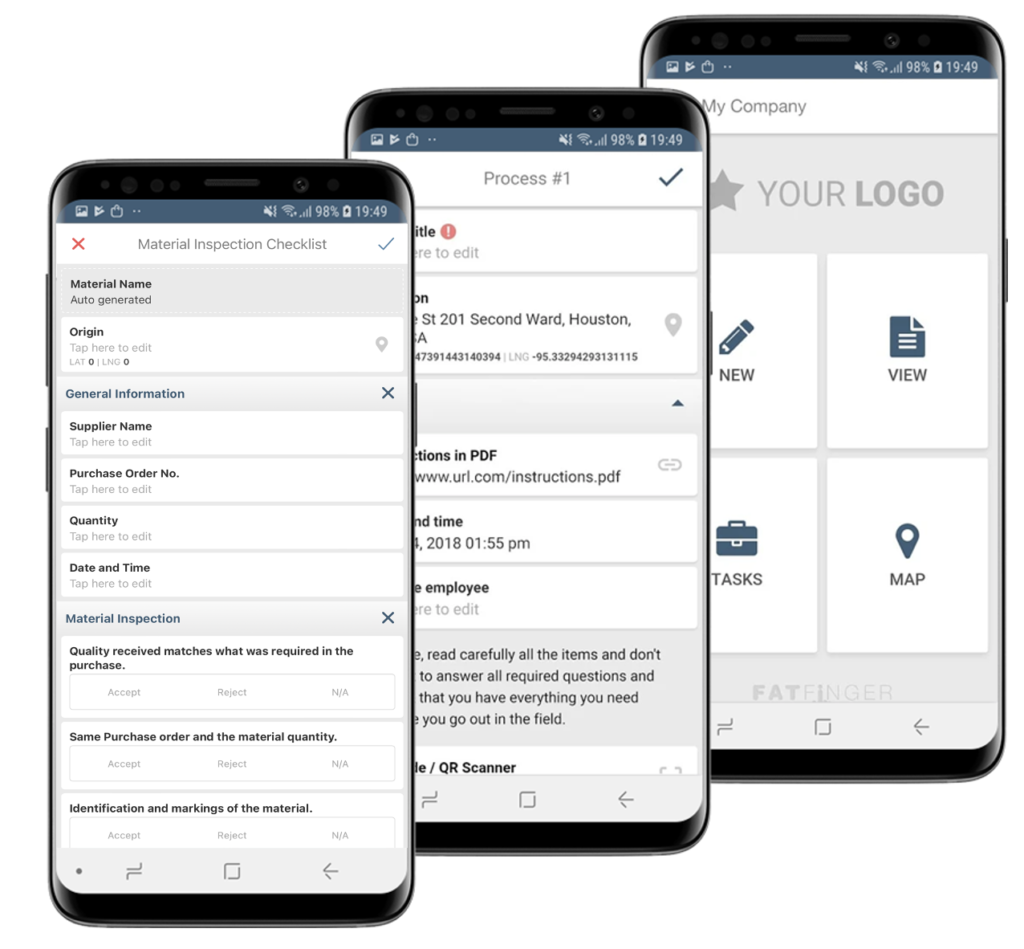

Effective Digital Material Inspection Checklist

A few different aspects should be included in a material inspection checklist.

1.There should be a check for the manufacturing date.

2.There should be a check for any damage that may have occurred during shipping or storage.

3.There should be a check for the material’s overall quality. This includes reviews for size, shape, surface finish, and material properties.

It’s hard to keep track of all the materials that come into your factory and even harder to know which ones are ready for production.

.

FAT FINGER is a trusted inspection management tool that helps manufacturers quickly and easily tag materials as accepted, conditionally accepted, or rejected during pre-production, which saves time and money by catching quality issues early.

With FAT FINGER, you can:

– Perform incoming inspections offline or online

– Schedule regular inspections and quality audits

– Capture photo evidence of tagged raw materials

– Automatically generate and share reports

– Assign actions for rejected/conditionally accepted items

– Gather digital signatures to authenticate results

-Customize according to your material inspection needs

Be confident that your manufacturing process is running smoothly and that any quality issues are resolved quickly and efficiently with FAT FINGER.

About FAT FINGER:

Ensure front-line teams do their work correctly every time. Drag & drop digital procedures that unlock operational excellence.

In seconds anyone can build and deploy enterprise-grade mobile applications using an easy drag-and-drop no-code builder.

FAT FINGER uses machine learning to coach app users in real-time to make safer and improved decisions.

Try building your digital procedure on FAT FINGER for free @ www.fatfinger.io