Preventive Maintenance

Take your engineering team to the next level with this dynamic preventive maintenance tool.

Trusted by companies all over the world

Before FAT FINGER

Unplanned downtime

Emergency maintenance caused by sudden asset failures is costly and impacts production.

Procedures are not followed

Without adherence to workflows, team accountability is at risk while asset reliability is decreasing.

No gaps, no lags – stay on top with preventive maintenance workflows

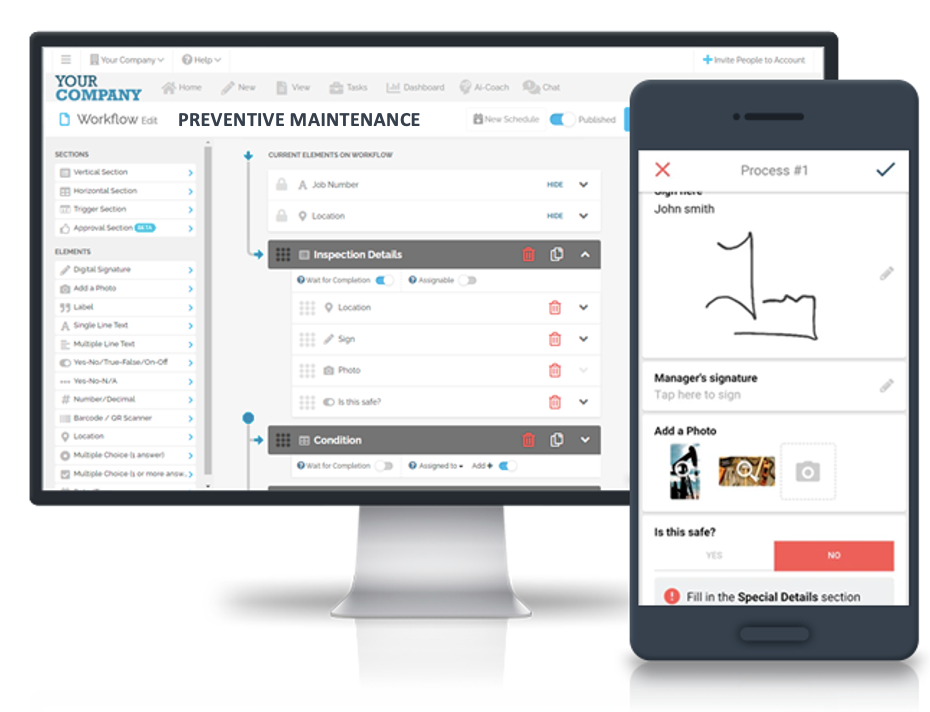

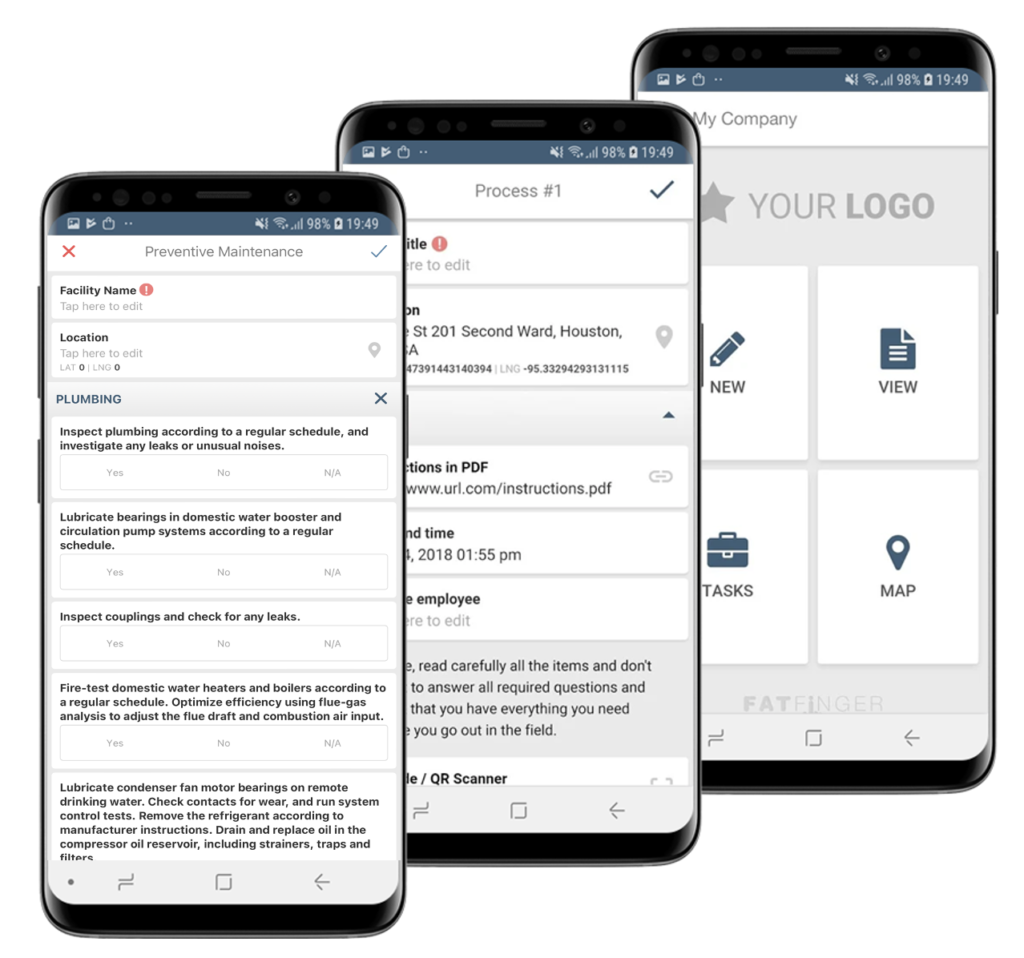

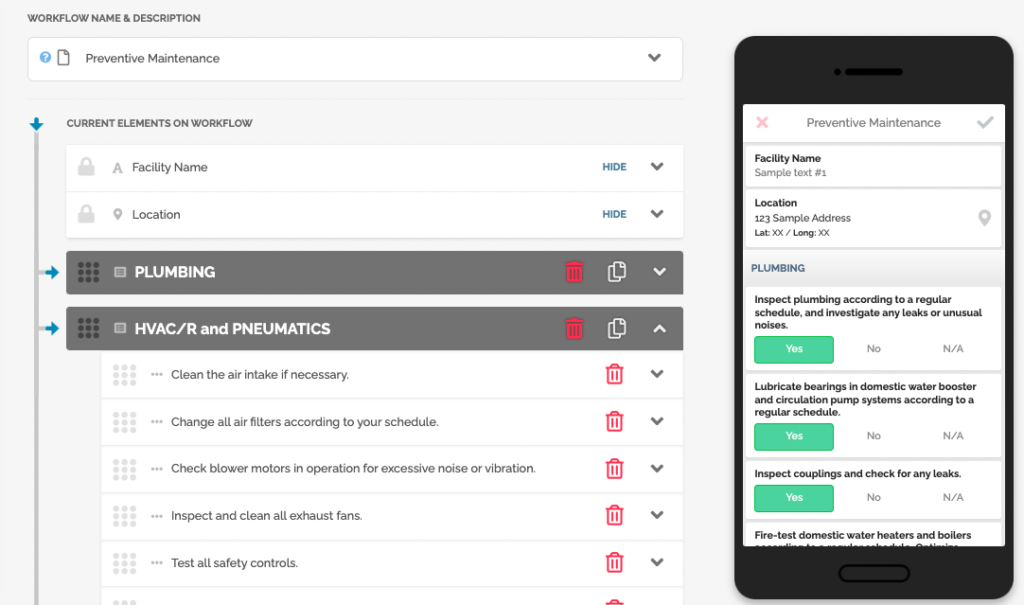

FAT FINGER provides easy-to-use workflows to help you manage your preventive maintenance program on the go. With our intuitive workflow, you can drag & drop digital procedure, control scheduling, and manage preventive maintenance tasks to keep your equipment running at peak performance.

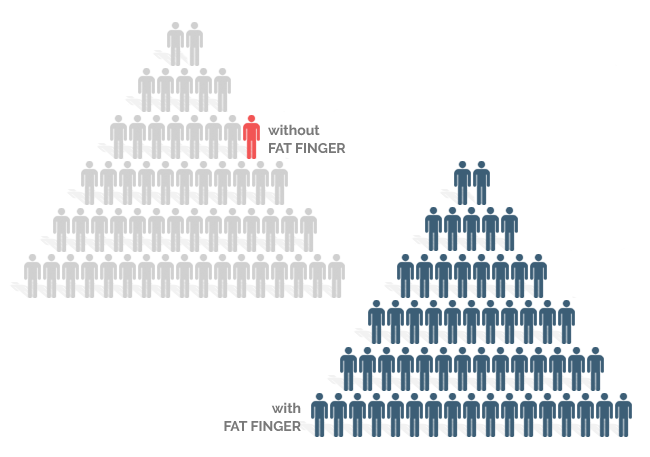

With everyone in sync, no task is missed

Managing maintenance checklists through FAT FINGER ensures that important tasks have not been overlooked and procedure have properly been followed. With our workflows, you can manage and monitor technicians and service providers’ work. Get a comprehensive view of all your assets, including repair history records, maintenance updates, SOPs and more.

“We have seen a significant reduction in downtime, delivery delays, and long-term costs associated with manual maintenance processes.We’re incredibly pleased with the results we’ve seen since incorporating FAT FINGER.”

Jay Williams, Reliability Engineer

Gain critical insights into your assets and boost reliability

Having access to the right asset data on each piece of equipment helps in anticipating maintenance so you can plan accordingly. Do integrations your way by connecting FAT FINGER into any system with our open API. Collect maintenance data on demand and make smarter decisions.

Change the way you work

Transition a world of reactive maintenance tasks into a centralized asset management platform.

Customized maintenance workflows made just for you

We empower EVERYONE to initiate and create positive change to streamline your company’s asset reliability and maintenance program no matter where you are. Access your own asset details and take customized work requests from creation to completion using your mobile device so you can fast when you needed.

FAT FINGER gets you results in maintenance

Committed to improving the way organizations manage their maintenance operations – trusted by thousand of users across the globe

31%

Saved in maintenance cost

97%

Feel in more control of their assets

38.75hrs

Reclaimed per week performing maintenance

84%

Improved overall equipment effectiveness. More data means more actionable insights!

What is Preventive Maintenance?

Preventive maintenance deals with the proactive approach used in manufacturing plants such as oil and gas to identify and address potential mechanical, electrical, or other issues before they become problems. It includes regularly scheduled inspections, tests, and preventive measures to maintain operations and production at a peak level of performance.

Preventive maintenance schedules ensure problems can be identified and addressed before they become too costly. Here are five benefits of preventive maintenance:

1. It extends machinery life by locating potential issues before they cause breakdowns.

2. It reduces associated costs since efficiency is improved and breakdowns are minimized.

3. Preventive maintenance makes better use of time by identifying potential problems that could lead to unscheduled downtime.

4. Preventive maintenance increases safety in the workplace by ensuring safe operating conditions for workers

5. It provides better quality control in production processes and eliminates unplanned downtime resulting from preventive repairs.

Preventive maintenance should be employed in all manufacturing plants to encourage more significant cost savings, extend asset lifespan, improve machine performance and ensure a safe work environment.

Don’t let a small problem turn into a big one.

Transition a world of reactive maintenance tasks into a centralized asset management platform.

Preventive Maintenance Best Practices with FAT FINGER

Here are a few maintenance guidelines that can help you optimize your performance to ensure you get the most effective maintenance program.

1) Implement maintenance management software.

Maintenance management software is an engineering best practice that enables preventive maintenance of assets and resources. This platform significantly reduces downtime, delivery delays, and long-term costs associated with manual maintenance processes by automating all preventive maintenance tasks across asset lifecycles. FAT FINGER is the perfect solution for companies looking to develop a successful preventive maintenance plan, as it offers a tailored and effective maintenance checklist.

2) Implement Performance Monitoring Devices

Installation of performance monitoring modules on running machinery can provide priceless business insights. This data, which may be collected in real-time or at specific intervals depending on the machine and module, can then be integrated with a centralized management system like FAT FINGER to give managers a comprehensive view of their business operations. By utilizing these specialized devices, businesses gain invaluable intelligence that helps them maximize their efficiency and overall success.

3) Training and Development

Ongoing education and training aren’t just advantageous for maintenance managers but offer extensive advantages to all staff members and executive leaders.Companies will see increased success when they employ a few proficient technicians with ever-growing knowledge, as opposed to continuously hiring new staff. Training programs are available in FAT FINGER software to help you stay up to date.

4) Maximize Machine Learning Protocols

Companies with limited resources can reap immense benefits from the capacity to regularly monitor and maintain their equipment according to previous maintenance intervals.

With FAT FINGER machine learning, decision-makers no longer need to guess when and how to move forward with maintenance efforts. Instead, they can easily obtain a comprehensive overview of the situation quickly and effectively.

Take advantage of FAT FINGER software’s Preventive Maintenance Checklist and optimize operations in your company today! With FAT FINGER, you can reduce downtime, delivery delays, and long-term costs associated with manual maintenance processes. Leverage the power of FAT FINGER’s tailored Preventive Maintenance Checklist today.

Start Preventive Maintenance the Right Way – with FAT FINGER!

About FAT FINGER:

Ensure front-line teams do their work correctly every time. Drag & drop digital procedures that unlock operational excellence.

In seconds anyone can build and deploy enterprise-grade mobile applications using an easy drag-and-drop no-code builder.

FAT FINGER uses machine learning to coach app users in real-time to make safer and improved decisions.

Try building your digital procedure on FAT FINGER for free @ www.fatfinger.io