Quality Control

See to it that what your customers get presents the best of your brand.

Trusted by companies all over the world

Before FAT FINGER

Low throughput

Without quality management software in their corner, industries are playing a high-stakes game of chance. Low throughput equals low profit.

Customer Dissatisfaction

Poor quality products contribute to customer mistrust, tarnished brand images and reduced customer loyalty.

Reach maximum production potential

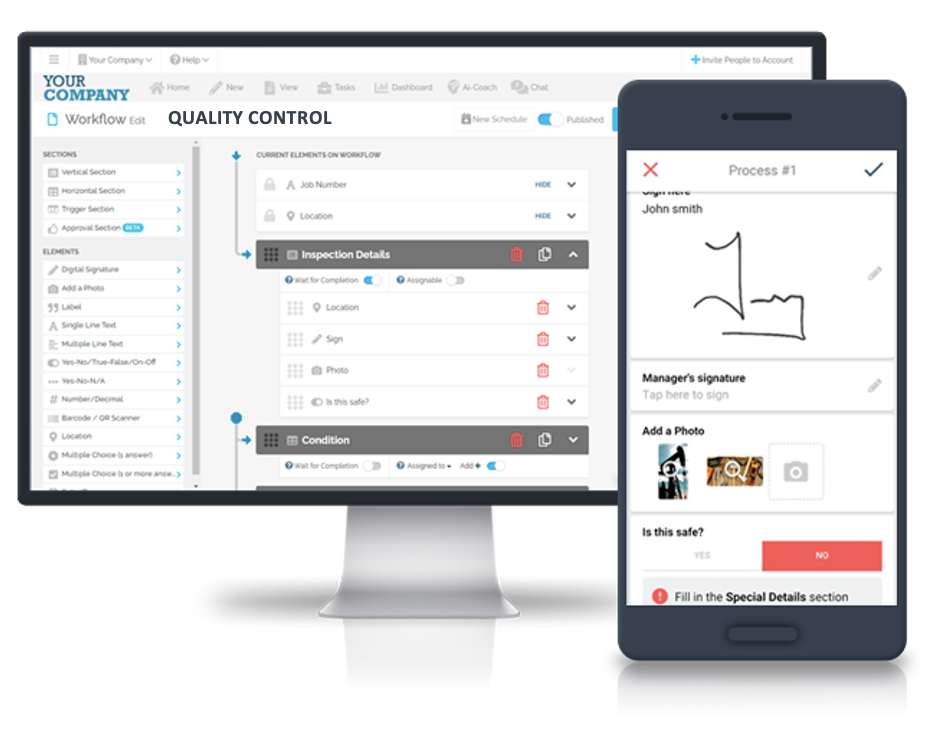

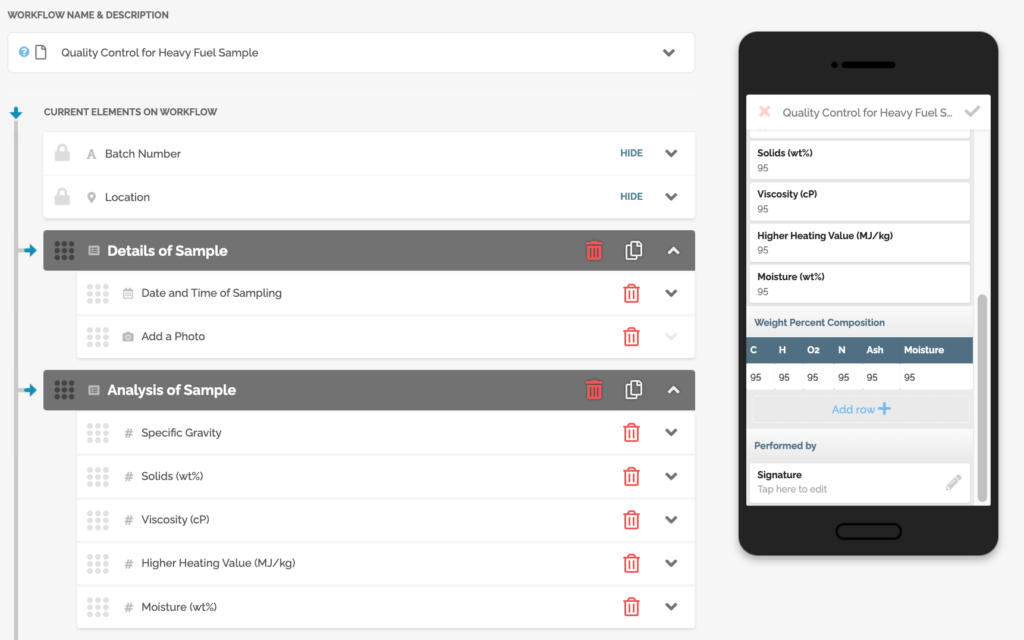

Sky is the limit with customized automated workflow. Smart workflow enables a seamless transition from paperwork processes to digital ones in minutes.Just drag-and-drop procedures directly into workflows without needing any coding knowledge. And with one click of a button, generate custom reports that will keep everyone on track for operational excellence.

Guaranteed customer satisfaction and brand loyalty

FAT FINGER provides actionable insights across the entire order processing process, so any potential issues can be addressed quickly and efficiently. Costs are reduced due to its efficient error tracking capabilities .With unparalleled data accuracy and comprehensive analytics , FAT FINGER is a powerful tool that puts loyalty at the forefront of your business.

“We’ve been using FAT FINGER’s Quality Control Checklist software for over a year now and it’s truly revolutionized how we conduct quality audits and inspections.”

David Andrews, Manufacturing Engineer

Unlock smarter decisions through better quality control insights

Get the inside scoop on your production with FAT FINGER. Live management dashboard gives you access to powerful real-time analytics so that nothing slips by. Take charge and make decisions that improve productivity – all this without even breaking a sweat.

Do more of what matters most

Manage your operations effectively in just a click.

FAT FINGER gets you results in operations

Committed to building sustainable operational excellence platform – trusted by thousand of users across the globe.

56%

Reduced costs

97%

Feel in more control of their operations

7.28hrs

Reclaimed per procedure

84%

Improved quality of output. More data means more actionable insights!

Quality control is critical for any industry that wants to produce products that meet customer expectations. Quality Control Checklists are vital because it:

1.Ensures that products meet customer expectations by verifying that the product development process is followed correctly.

2.Can identify potential problems early on in the process before they result in defects or customer complaints.

3.Allows industries to track progress towards meeting quality goals.

In short, Quality Control exist to improve Quality Standards throughout the industry by providing a systemized method of identifying & correcting errors along every step of production – from design to delivery.

6 Steps to Create an Effective Quality Control Checklist

Here are the steps to creating a quality control inspection checklist:

1. Identify the specific Quality Control criteria that you will be assessing.

2. Once you have identified the specific Quality Control criteria, you need to decide how you will measure compliance.

3. Develop a checklist that includes all of the Quality Control criteria you will be assessing.

4. Once you have identified the Quality Control criteria and potential defects, you can start creating your quality control inspection checklist.

5. Test your Quality Control inspection checklist before using it on actual products.

Join the industry-wide move towards higher quality standards

Quality Control Checklist with FAT FINGER

Integrating quality management into your business process can proactively catch product defects and prevent them from affecting the consumers and your organization’s hard-earned reputation.

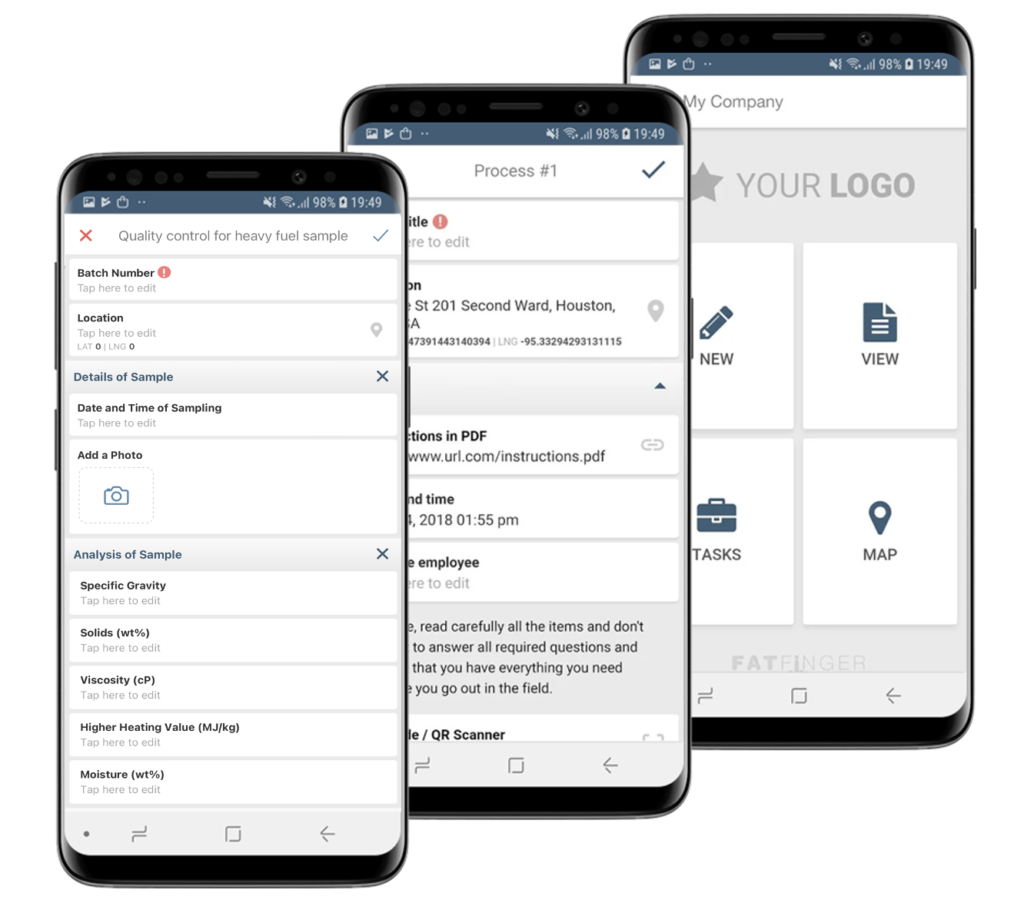

FAT FINGER Quality Control Checklist is a free, customizable digital checklist that the industry can use to help prevent insufficient data and poor-quality reports.

The digital checklist helps you to attach photos while conducting complete quality audits and inspections to ensure continuous improvement.

It also enables businesses to utilize quality-related forms and checklists and to find other templates that may be relevant to their business in the FAT FINGER Public Library.

Implementing a quality control checklist with FAT FINGER into your business process is an intelligent way to keep your product quality high and your manufacturing risks low.

Check out our video below on how FAT FINGER works, and see how easy our quality management software provides the tools you need to streamline your quality control processes and improve product quality.

About FAT FINGER:

Ensure front-line teams do their work correctly every time. Drag & drop digital procedures that unlock operational excellence.

In seconds anyone can build and deploy enterprise-grade mobile applications using an easy drag-and-drop no-code builder.

FAT FINGER uses machine learning to coach app users in real-time to make safer and improved decisions.

Try building your digital procedure on FAT FINGER for free @ www.fatfinger.io