SDSs are essential documents in material testing, their digitization makes ExxonMobil’s manufacturing processes more reliable and accountable despite their size.

Any large manufacturing facility should digitize its quality control process to eliminate the need for paper-based forms and reduce the risk of errors and inconsistencies.

FAT FINGER provides digital workflow solutions for ExxonMobil.

This is why we recommend that the material inspection checklist in your manufacturing processes must fulfill the following:

- A proper pre-inspection plan,

- Inspection of the incoming materials,

- Integration of FAT FINGER’s digital procedures.

Here’s the bottom line, manufacturers will experience improved decision-making when they use the recommended material inspection checklist.

Pre-inspection Planning

An accurate and efficient material inspection requires a proper pre-inspection plan.

During the planning phase, the following factors must be considered:

- Inventory management

- Scheduled inspection time frames

- Required inspection resources

- Safety considerations

Inventory Management

It’s essential to have an up-to-date inventory of all materials in the manufacturing facility throughout multiple stages of manufacturing

Regularly checking inventory for accuracy can prevent ordering duplicate materials or running out of necessary items during the production process.

Matter of fact, you will need to check all three types of inventory:

- Raw material inventory. This is the inventory of basic and natural materials used in the first stage of production.

- Work In Progress (WIP) Inventory. These are raw materials that were turned into parts or segments of the finished product. They are partially finished and are waiting for the next production process.

- Finished goods inventory. These are the end-of-the-line products that are ready for shipment. In most cases, they are created when the work-in-progress materials are put together.

FAT FINGER provides your large manufacturing facility with a smooth and appropriate inventory management process.

It recommends using either of three strategies to manage your inventory:

- Pull strategy. This process puts the management process in the client’s hands. You supply your product according to a customer’s demand.

Even though the process is best suited for small and medium manufacturing facilities, FAT FINGER provides a rapidly adaptive digital platform that can adjust to customer demand when needed. This process will help you keep the inventory costs low.

- Push strategy. This strategy calls for you to release products according to what you think is the level of customer demand. It is riskier because when the customer demand is lower, you will be left with excess products in your inventory. Consequently, you will be forced to invest more in storage and preservation.

Most large manufacturing facilities prefer this strategy. However, FAT FINGER allows you to apply a more accurate pull strategy.

- Just In Time (JIT) strategy. This is a mixture of both push and pull strategies. You anticipate customer demand by having raw materials in hand but only produce the items that are in actual demand. This way, you keep your overhead costs low.

FAT FINGER’s material inspection platform also runs smoothly and avoids delivery delays when trying to meet unexpected demands.

Use FAT FINGER to guarantee visibility by monitoring the inventory management process, operation, and inspection from one place. It will digitize processes, automate data insights and conduct efficient inspections.

Here is a sample table of inventory management:

| Material | Quantity | Location | Last Inspection |

| Electrical Wires | 200 ft | Warehouse A | 2 months ago |

| Drywall Sheets | 100 pcs | Warehouse B | 3 months ago |

| Plumbing Fixtures | 50 pcs | Warehouse C | 1 month ago |

Scheduled Inspection Time Frames

You must consider the production schedule and expected delivery times of materials when planning inspection times.

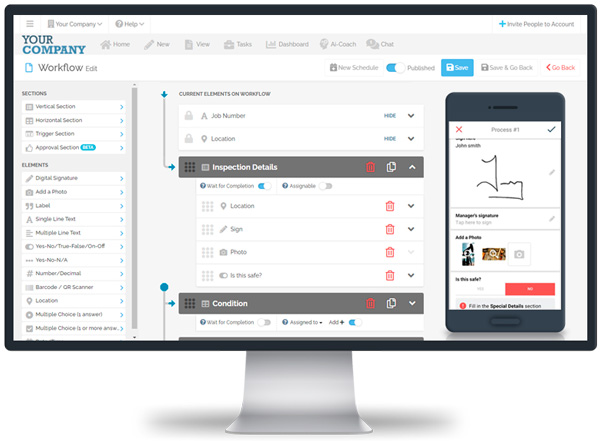

FAT FINGER simplifies this process by ensuring your workers can build and deploy enterprise-grade mobile applications to aid your facility’s quality control by using our drag-and-drop, no-code builder with real-time coaching for frontline workers.

| Expert Tip: Real-time coaching for frontline workers through enterprise-grade mobile applications improves the effectiveness of quality control in manufacturing. |

They can rapidly update the production schedule to match the expected delivery times and inspection times.

Here is a sample table of scheduled inspection time frames:

| Inspection Type | Frequency | Timeframe |

| Structural Inspection | Annual | Summer |

| Electrical Inspection | Bi-annual | Spring and Fall |

| HVAC Inspection | Quarterly | Winter, Spring, Summer, and Fall |

| Plumbing Inspection | Bi-annual | Spring and Fall |

Required Inspection Resources

To conduct thorough inspections, appropriate resources should be available, including:

- Trained personnel. They have the knowledge and expertise to identify and analyze different types of materials, defects, and hazards that may exist in the manufacturing process. They will be able to interpret data on the FAT FINGER platform and prevent issues in the future.

- Inspection instruments. These provide accurate and objective measurements of various material properties such as dimensions, hardness, and strength. This way, they provide a basis for traceability and quality assurance.

When using digital instruments, it will be easier to transfer their data using FAT FINGER’s platform.

- Safety equipment. Some materials may be hazardous. Safety equipment prevents injuries and illnesses that may result from exposure to these materials. They include gloves, helmets, safety glasses, and respirators.

- Standard operating procedures (SOPs). These provide a standardized framework for conducting material inspection, including the steps to be taken, the equipment to be used, and the criteria for determining whether materials meet the required specifications.

They can also be used for documenting the inspection results, identifying trends, and providing a basis for continuous improvement.

Here is a sample table of required inspection resources:

| Resource | Quantity | Status |

| Inspection Instruments | 5 | Available |

| Safety Equipment | 10 sets | Available |

| Standard Operating Procedures (SOPs) | 20 copies | Updated |

| Trained Personnel | 3 | On leave, replacement needed |

Safety and Reliability Considerations

Safety should be the top priority during inspections.

Machinery and equipment should be inspected regularly to prevent equipment malfunction or failure during a production process.

It is essential to verify that the equipment is operating correctly, as this will impact the quality and safety of the final product.

Before inspections, it’s essential to ensure that all equipment is shut down, and hazardous materials are removed.

All measuring devices and tools should also undergo inspection for accuracy and precision. In some cases, defective measuring devices and tools could directly impact the final product’s quality, and it is important for inspectors to identify any inconsistencies or inaccuracies within the equipment.

Here’s how you go about it, you check the validity of equipment certificates and calibration of your equipment.

It is important to note that inspections should not be limited to production tools and equipment only. Maintenance and support equipment such as ladders, hoists, and elevating platforms also require inspection to reduce the risk of accidents and injuries.

Proper equipment inspections can help manufacturing facilities comply with OSHA and federal regulations as it relates to machine protection and employee safety.

With FAT FINGER, companies can streamline their inspection processes and enhance their efficiency further.

Incoming Material Inspection

In any manufacturing facility, the incoming materials received for production play a vital role in ensuring the quality and safety of the final product.

Inspecting incoming material involves ensuring that the materials meet the specifications and standards below.

Documentation Requirements for Incoming Materials

The first step in the incoming material inspection process is verifying that all the required documentation is present and up-to-date.

The documentations include:

- Certificates of Analysis (CoA). This provides information about the physical and chemical properties of a material, including its composition, purity, and potency.

It is issued by the manufacturer of the material. Your facility requires to ensure the material meets the expected specifications.

- Material Safety Data Sheet (MSDS). This is a document that provides information about hazards associated with a material, including its potential health effects, physical and chemical properties, and safe handling procedures.

MSDSs are typically provided by the supplier or manufacturer of the material. You will require it to ensure that the material is handled safely and your workers are aware of its potential hazards.

- Packing slip. This document accompanies the shipment materials and provides information about the quantity, weight, and description of the contents.

It is normally provided by the supplier and you can use it to verify that the correct materials have been received and track the inventory levels.

- Purchase order. This is a document that specifies the quantity, price, and delivery date of materials ordered from specific suppliers.

It is generated by your manufacturing facility and is used to ensure that the correct materials are ordered and delivered on time.

When you feed the FAT FINGER’s mobile platform with accurate and complete documentation for the materials, you will be able to access them from anywhere at any time. This improves the manufacturing quality control process by reducing delays in production.

Quality and Safety

The inspection of incoming materials starts by verifying the physical characteristics of the materials.

The materials should be checked for consistency in color, texture, and smell.

With FAT FINGER’s mobile platform, this only involves viewing the safety data sheets at any time and comparing it with the material’s characteristics.

Any deviations from the expected characteristics could indicate contamination or degradation of the materials, which can affect the final product.

Hazardous materials require special handling and storage, and their inspection should include a review of their safety data sheets.

Quantities and Packaging

The next step in the incoming material inspection process is verifying the quantities and packaging of the materials.

The quantities received should match the quantities ordered, and the packaging used should be appropriate for the materials.

When using FAT FINGER’s mobile platform, you will only need to view the packing slip and purchasing order, then compare them with the materials.

Any damages or issues with the packaging will affect the quality of the materials.

The documentation, physical characteristics, quantities, and packaging should all be inspected during the incoming material inspection process to ensure that the materials are suitable for production.

A thorough inspection can help prevent quality issues and delays in production, ultimately leading to a more efficient, cost-effective, and successful large manufacturing facility.

FAT FINGER

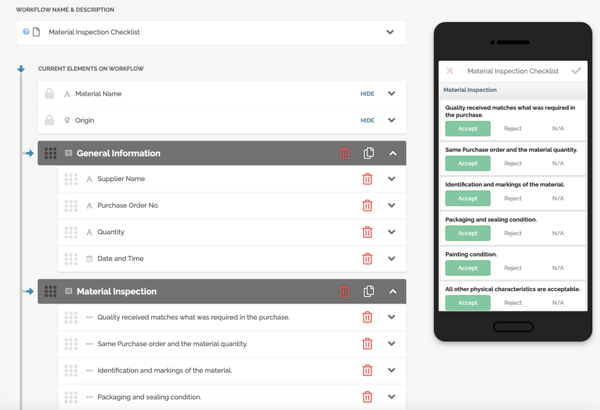

To make material inspection more efficient and accurate, manufacturers use the services of FAT FINGER, a comprehensive material inspection checklist tool.

FAT FINGER is a cloud-based platform that enables manufacturers to create, customize, and automate their inspection checklists for various materials, including metals, plastics, and composites.

It is the easiest and most flexible digital procedures platform in the world.

We provide front-line workers with easy, fast, and flexible digital procedures that drive operational excellence in manufacturing. The procedures can visualize inspection processes and provide real-time data capture and analysis.

Well-Pro is an example of an oil field service company that we helped reduce its operational charges by more than $1,000,000. We did this while improving visibility into field operations and connectivity into home office systems and processes.

“Using FAT FINGER allows us to reduce days outstanding, lost tickets and see our exact daily sales numbers which is a huge benefit for planning our business.” — Casey Roling—VP of Operations, Well-Pro.

FAT FINGER also provides advanced features such as automatic report generation and analytics, enabling manufacturers to track the quality of their materials over time and identify areas for improvement.

The platform can be integrated with existing manufacturing software systems, providing a seamless and integrated inspection process. This way, FAT FINGER can help manufacturers ensure that their products meet the highest standards of quality and reliability.

It allows inspectors to carry out inspections in real time, eliminating the need for paper-based forms and reducing the risk of errors and inconsistencies.

The video below shows the digital procedures of how anyone can build and deploy enterprise-grade mobile applications using an easy drag-and-drop no-code builder with FAT FINGER.

Overall, FAT FINGER aims to become the world’s most used, and most profitable no-code digital procedures platform.

| Why This Matters: Utilizing digital procedures and platforms in your inspection process can lead to seamless integration, real-time updates, and automated data insights, making your manufacturing process more efficient. |

Digitize your Quality Control

The implementation of a digitized material inspection checklist is an effective way to maintain quality control.

Use FAT FINGER throughout your pre-inspection planning and material inspection to avoid paper-based forms and reduce the risk of errors and inconsistencies.

A standard operating procedure with a digitized material inspection checklist will ensure that the inspection process is consistent and thorough.

We encourage all large manufacturing facilities to implement material inspection checklists and maintain quality control to ensure the production of high-quality products.

Share on LinkedIn