Line Changeover

Get the most out of your production by seamlessly transitioning between processes with our line changeover solution.

Trusted by companies all over the world

Before FAT FINGER

Low throughput during changeover

Manual processes and repetitive tasks during line changover are time-consuming and often lead to errors which decrease throughput.

High costs from manual entry

Operational processing costs can quickly add up when relying on manual entry that requires more manpower.

Skyrocket your production levels with automated workflows

Get ready to experience the effortless power of streamlined operations with our intuitive workflow. In mere minutes, turn your checklists, SOPs and changover processes into a smart digital system that drives excellence directly where it counts—and generates professional reports at just one click.

Take your line changeover into a cost effective future with digitalization

Cutting down tedious tasks like manual reporting and quality monitoring is now easier than ever. Get your team synced up in no time with automated recurring scheduling so everyone’s on the same page without any lost work hours – more productivity, less stress.

“FAT FINGER is a game changer for our production line clearance process.We can now streamline our production lines with confidence knowing that everything is right at our fingertips.”

Tom Taylor, Production Manager

Greater visibility means smarter decision

Every single piece of information captured by FAT FINGER users will feed your company analytics in real time. With FAT FINGER, you can see critical production information in a live management dashboard and take action to make decisions that will increase your productivity.

Do more of what matters most

Manage your operations effectively in just a click.

FAT FINGER gets you results in operations

Committed to building sustainable operational excellence platform – trusted by thousand of users across the globe.

56%

Reduced costs

97%

Feel in more control of their operations

7.28hrs

Reclaimed per procedure

84%

Improved quality of output. More data means more actionable insights!

Line changeover or line clearance is the process of verifying that all line changeover activities have been completed and that the line is ready to resume production.

The benefits of line clearance include reduced downtime, improved line efficiency, and increased product quality.

Shop floors are constantly changing; manufacturers must introduce new products, discontinue old ones, adjust production schedules, and more. With so many moving parts, line changeovers must be managed carefully to avoid disruptions in production. By verifying that all necessary line changeover activities have been completed, line clearance helps to ensure a smooth, efficient manufacturing process.

3 Steps Involved During Line Clearance Procedures

1. Clearing the line involves removing all products from the line and ensuring that no product remains in any of the line equipment. This step is essential to prevent cross-contamination of products.

2.Cleaning the line involves sanitizing all surfaces that will come into contact with the product. This step is essential to prevent bacteria from contaminating products. It also involves removing all product build-up and debris from the line.

3.Inspection is conducted to ensure that the line is clear and clean and that all equipment is in good working order. All moving parts should be lubricated, and all electrical connections should be secure.

We make your line changeover as smooth as possible

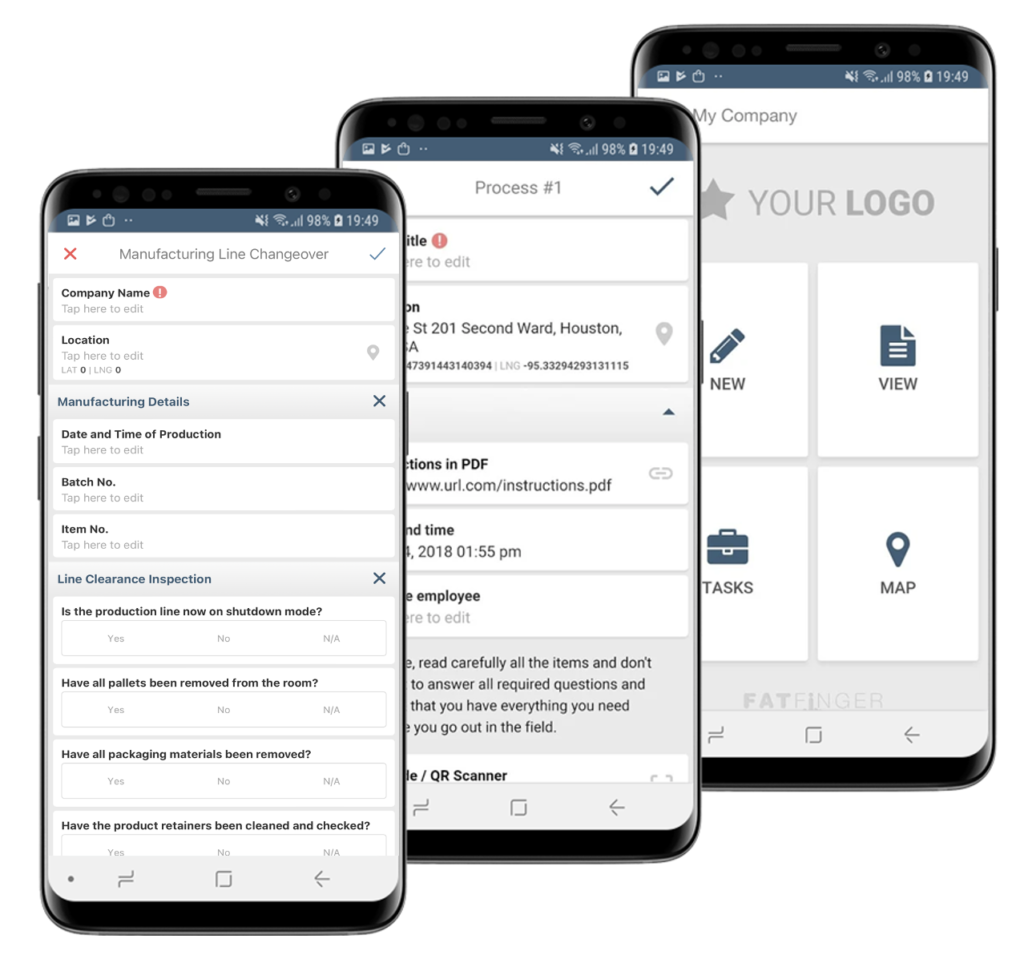

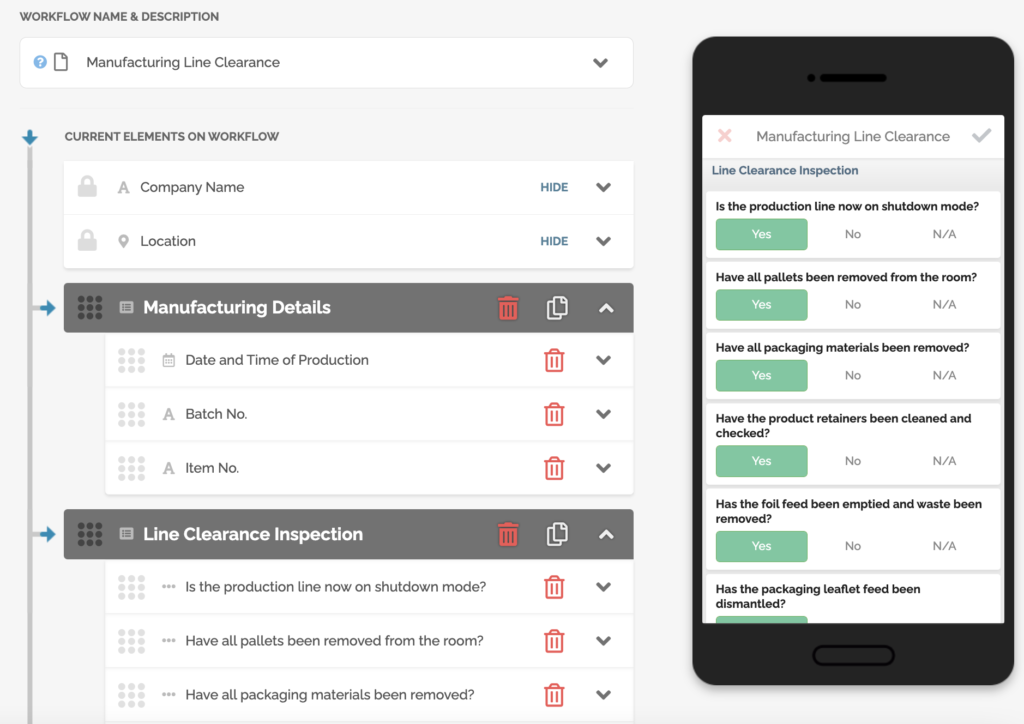

Implementing Digital Line Clearance Checklist

In modern manufacturing, line clearance is an essential part of quality control. By using a digital line clearance checklist, manufacturers can streamline the process and reduce the chances of human error.

A CXV Global survey of 30 pharmaceutical professionals found that 100% of respondents had experienced a line clearance error in the past year, and 96% said their current line clearance process takes more than 60 minutes.

Do you spend way too much time double and triple-checking that you didn’t leave anything important off your checklist when clearing a production line?

With FAT FINGER, all the necessary information is stored in one place, and anyone on the production line can quickly access it. Moreover,

-Remarks, corrective actions, and photos collected during line clearance can be added to the workflow.

-Generate reports on-site and send them to relevant stakeholders via email, PDF, or web link. This way, everyone can stay up-to-date on the latest information.

-Assign tasks and schedule your clearance line inspection directly from the app. This ensures everyone is on the same page and no one misses a beat.

Imagine if you could clear your production line with confidence, knowing that you had everything you needed right at your fingertips. With FAT FINGER, that’s now a reality. So why wait? Get started today!

About FAT FINGER:

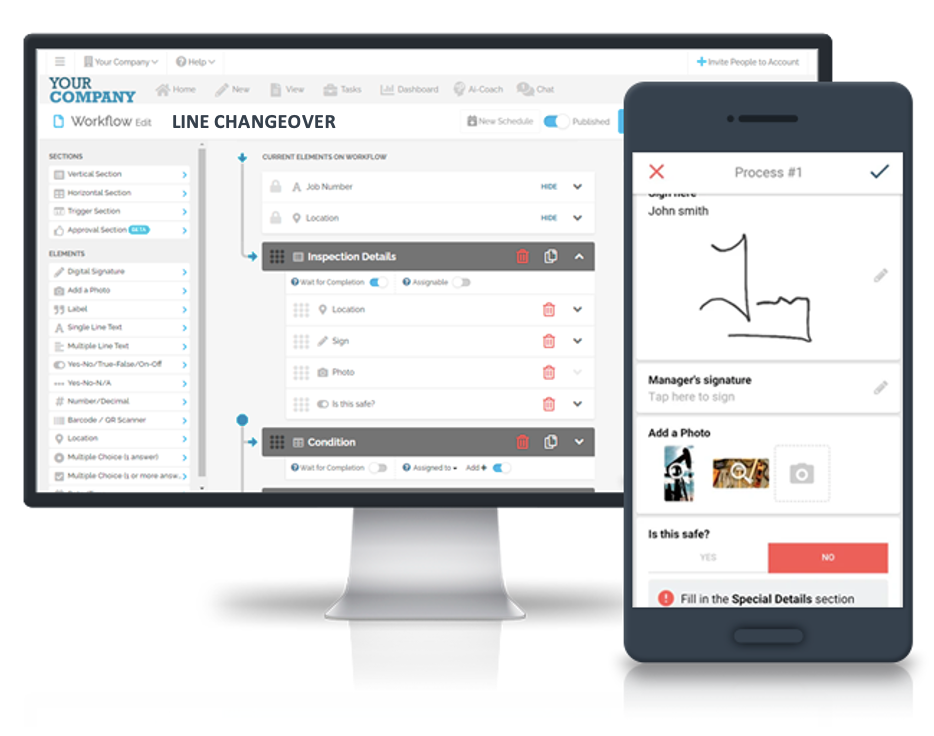

Ensure front-line teams do their work correctly every time. Drag & drop digital procedures that unlock operational excellence.

In seconds anyone can build and deploy enterprise-grade mobile applications using an easy drag-and-drop no-code builder.

FAT FINGER uses machine learning to coach app users in real-time to make safer and improved decisions.

Try building your digital procedure on FAT FINGER for free @ www.fatfinger.io