Job Hazard Analysis

Stay ahead of the game. Anticipate where potential hazards could arise and take preventative action.

Trusted by companies all over the world

Before FAT FINGER

Non-compliance

Poor hazard analysis tools can lead to non-compliance with regulatory standards, resulting in fines and accidents damaging the company’s reputation.

Increased likelihood of injury

Without JHA software, teams are drastically increasing the likelihood of injury and substandard job performance among employees by failing to assess potential hazards in their jobs.

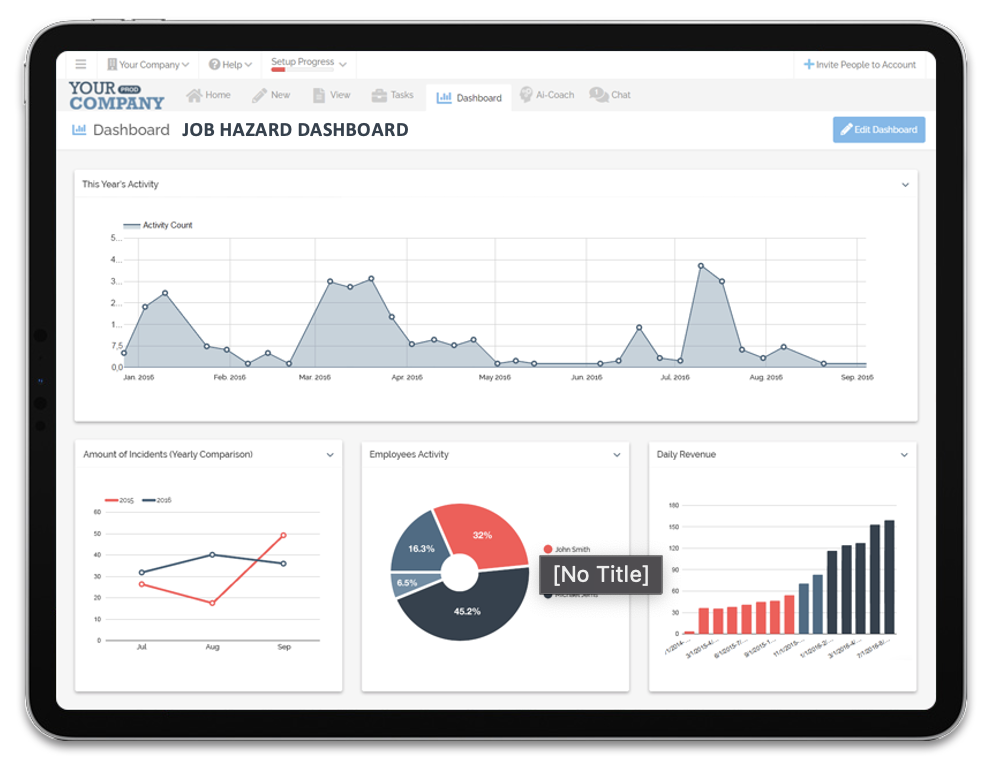

Manage hazards and reduce incident rate in real time

Protect your team and operations with FAT FINGER. Gain valuable insight in real-time, allowing you to catch dangerous situations before they become hazardous. See what can be done to strengthen safety protocols across the board.

“We would highly recommend this digital solution to anyone looking for an easy way to identify potential hazards with minimal time and effort required!”

Johnson Martin, Safety Manager

Identify, prioritize, communicate and control hazards

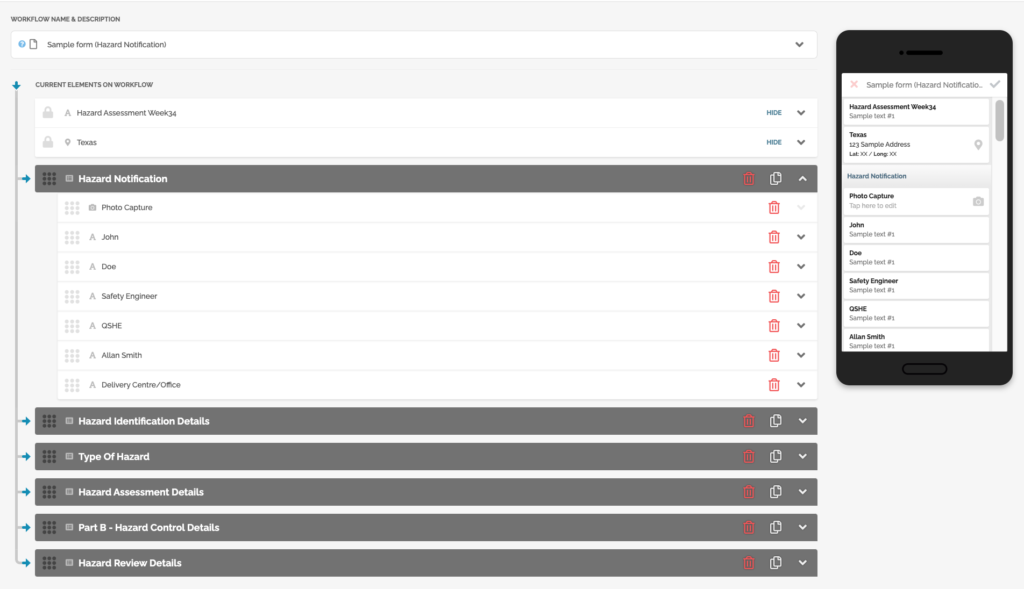

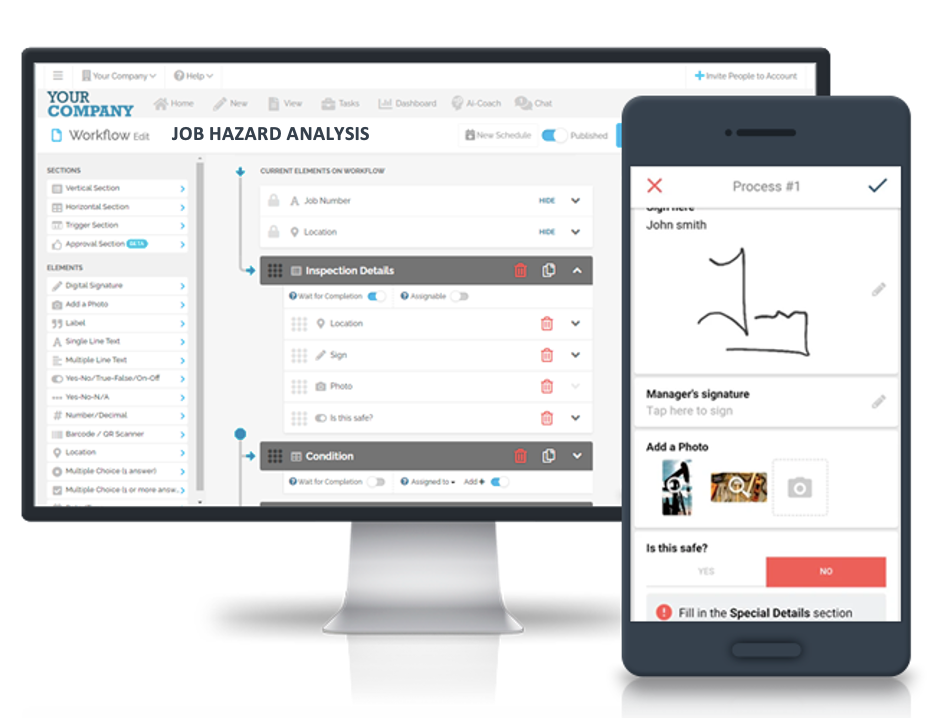

Unlock the power of customization with FAT FINGER and build a hazard analysis tailored to your needs in no time. FAT FINGER’s workflow is designed to streamline the data collection process. Customize your data collection with images and video to create workflows with No-Code directly where work is done. Automatically generate report with one click and share them with stakeholders.

“We are so impressed by the convenience, accuracy, and ease-of-use that FAT FINGER offers.I can confidently say that FAT FINGER has revolutionized our hazard assessment process.”

Jenny Miller, Director of Safety and Compliance

FAT FINGER drives safety culture across the organization

With FAT FINGER, your company can keep up with the lightning speed of business. Unlocking access to No-Code solutions for everyone in the organization – from frontline workers to executives – means transforming challenges into real profits. Instead of just keeping pace, get ahead and become compliant today!

Transform your organization’s workplace safety in just a click

Job hazard analysis made easy for everyone

We empower EVERYONE to initiate and create positive change to improve the company’s safety records. The only way to keep up with the speed at which the world moves today is to empower everyone from the front-line worker to the executive.

FAT FINGER gets you results in safety

Achieve guaranteed compliance, data-driven decisions, and increased productivity with FAT FINGER

38%

Fewer recorded incidents

97%

Feel in more control of their operations

7.28hrs

Reclaimed per procedure

44%

Improved procedure adherence. More data means more actionable insights!

Job Hazard Analysis is critical because it allows you to take proactive measures to control or eliminate potential hazards before they result in an accident or incident. Identifying risks early, can save lives, reduce injuries, and minimize property damage.

Job Hazard Analysis is the foundation for hazard control. JHA helps to prioritize controls by identifying the most severe hazard first. Hazard identification helps to establish baseline data for comparisons. For example, if you identified ten hazards in the workplace, and after implementing hazard controls, you only identified two hazards, you can show that the hazard controls are adequate.

How to Effectively Perform a Job Hazard Analysis?

Effectively perform hazard analysis by following the steps below:

Step 1: Identify the hazard

Common hazard categories include physical hazards, chemical hazards, biological hazards, and ergonomic hazards.

Step 2: Evaluate the hazard

Evaluate to determine the potential severity and likelihood of an accident or incident occurring.

Step 3: Take Action to Control the Hazard

There are a variety of ways to control hazards, including: eliminating the hazard, substituting a less hazardous material engineering controls and administrative controls.

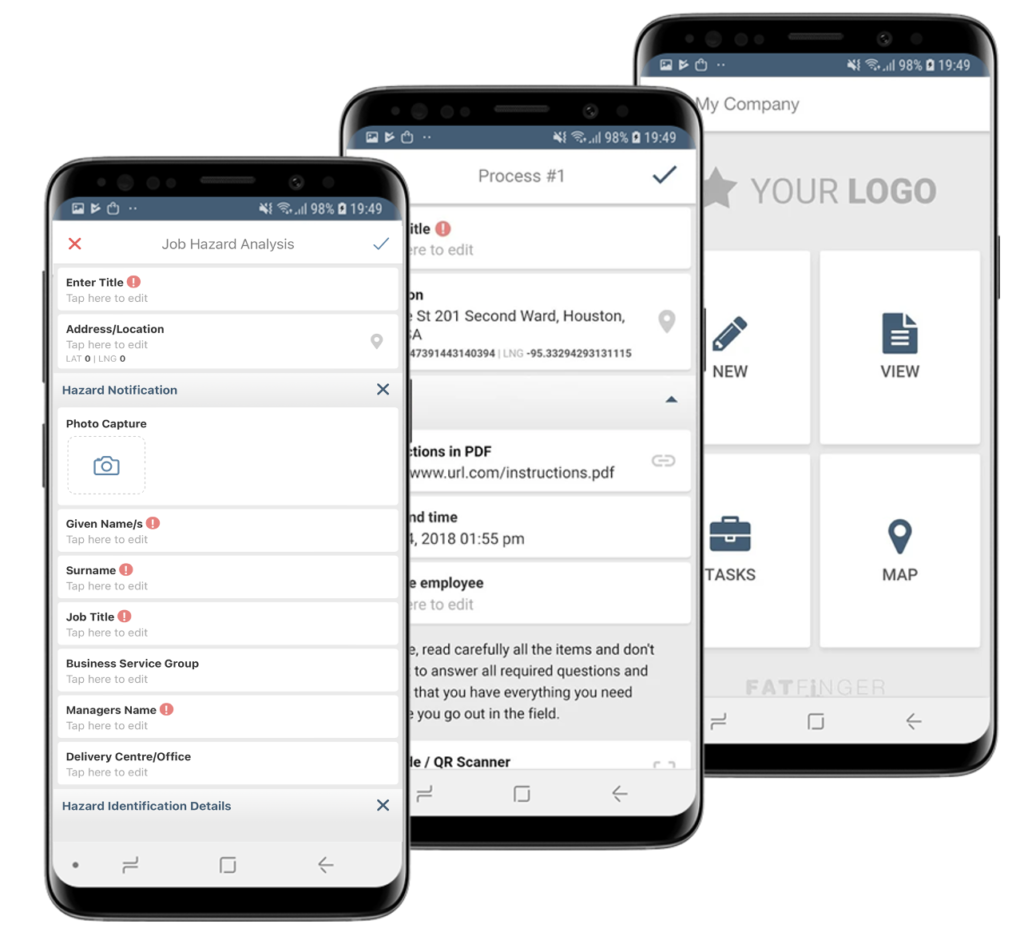

It’s hard to keep track of everything when you’re walking around a facility, inspecting for hazards. FAT FINGER is the solution. With our mobile app, you can easily capture media-rich knowledge with images and video to create Job Hazard Analysis workflows with no code directly where work is done.

Effective job hazard analysis starts here

Empower your Job Hazard Analysis with FAT FINGER

A digital Job Hazard Analysis checklist like that of FAT FINGER has revolutionized how workplaces identify and control hazards, especially in the oil and gas, energy, and manufacturing sectors. FAT FINGER is:

USER-FRIENDLY.The hazard identification checklist is digital and easy to use. Anyone can quickly learn how to use it with a few minutes of training.

EFFICIENT.A digital hazard identification checklist is faster and easier to use than a paper-based hazard identification checklist because you can quickly input data and add photos directly.

COLLABORATVE.With a digital hazard identifier, you can easily share the hazard identification checklist with others in your organization.

GOAL-ORIENTED.With a digital hazard identification checklist, you can easily track the type of hazards in your workplace and develop plans to control them.

FAT FINGER’s digital hazard identification checklist is easy to use and can help you improve the safety of your workplace.

FAT FINGER was created by safety professionals who understand the importance of capturing and communicating hazard information quickly, accurately, and efficiently.

Our mobile app makes it easy for you to take pictures and videos of your work area so you can identify potential hazards and create workflows without any coding required. With FAT FINGER, hazard assessment is simple. Get started today by downloading our free trial!

About FAT FINGER:

Ensure front-line teams do their work correctly every time. Drag & drop digital procedures that unlock operational excellence.

In seconds anyone can build and deploy enterprise-grade mobile applications using an easy drag-and-drop no-code builder.

FAT FINGER uses machine learning to coach app users in real-time to make safer and improved decisions.

Try building your digital procedure on FAT FINGER for free @ www.fatfinger.io