Facility Inspection

Ensure your facility keeps running without a hitch with this effective facility inspection workflow.

Trusted by companies all over the world

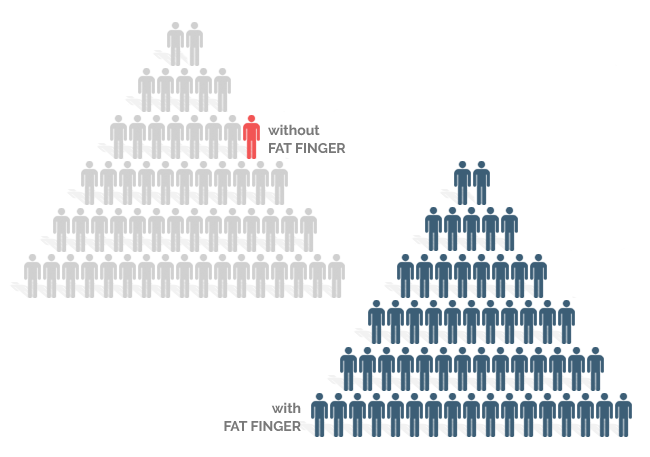

Before FAT FINGER

Low efficiency

Manual facility inspection reporting may be incomplete or inaccurate, leaving key facts out of the report and leading to ineffective solutions.

High costs

Operational processing costs can quickly add up when relying on manual entry that requires more manpower.

Elevate your team’s facility inspection to new heights

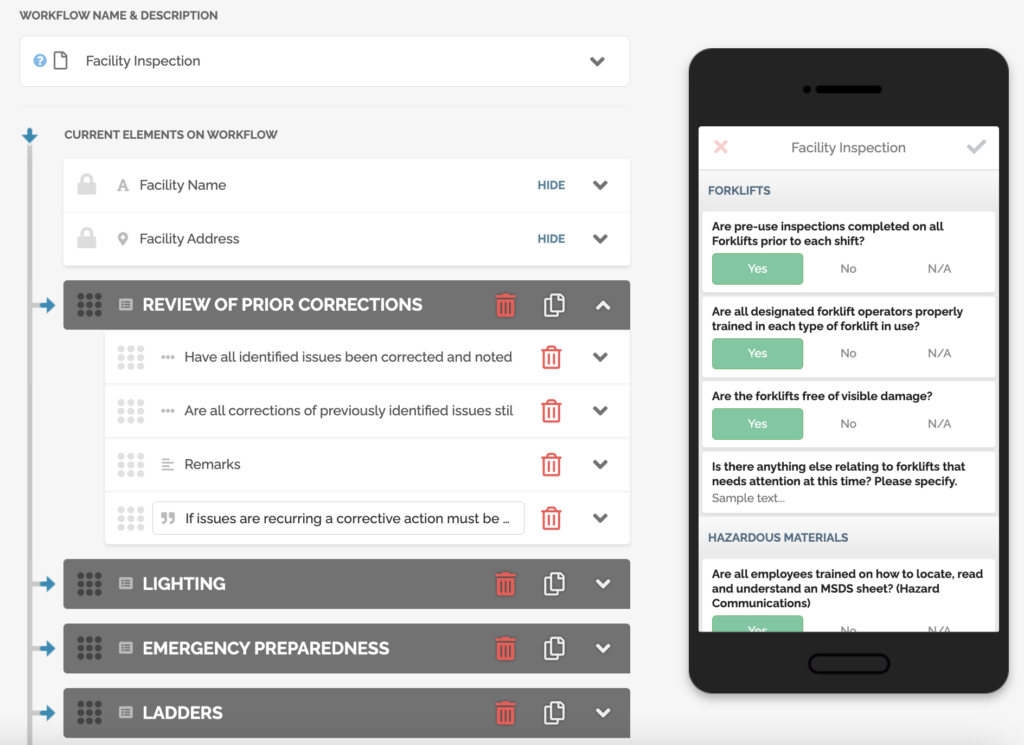

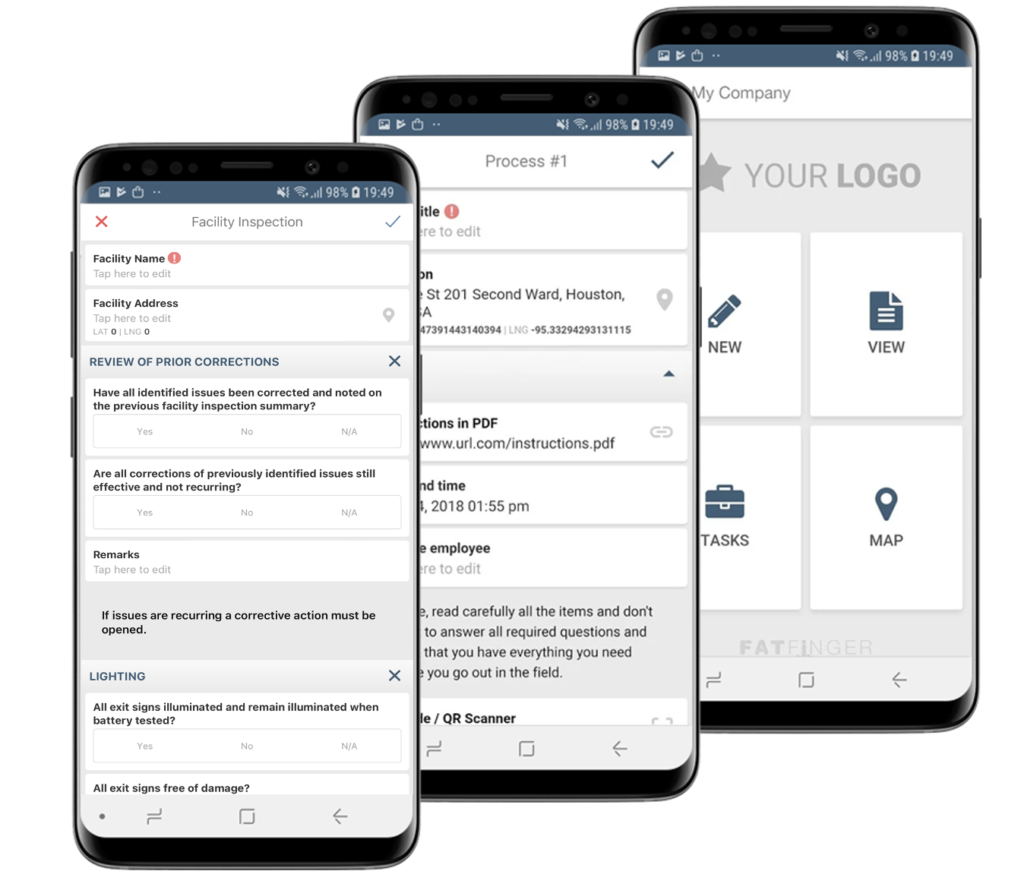

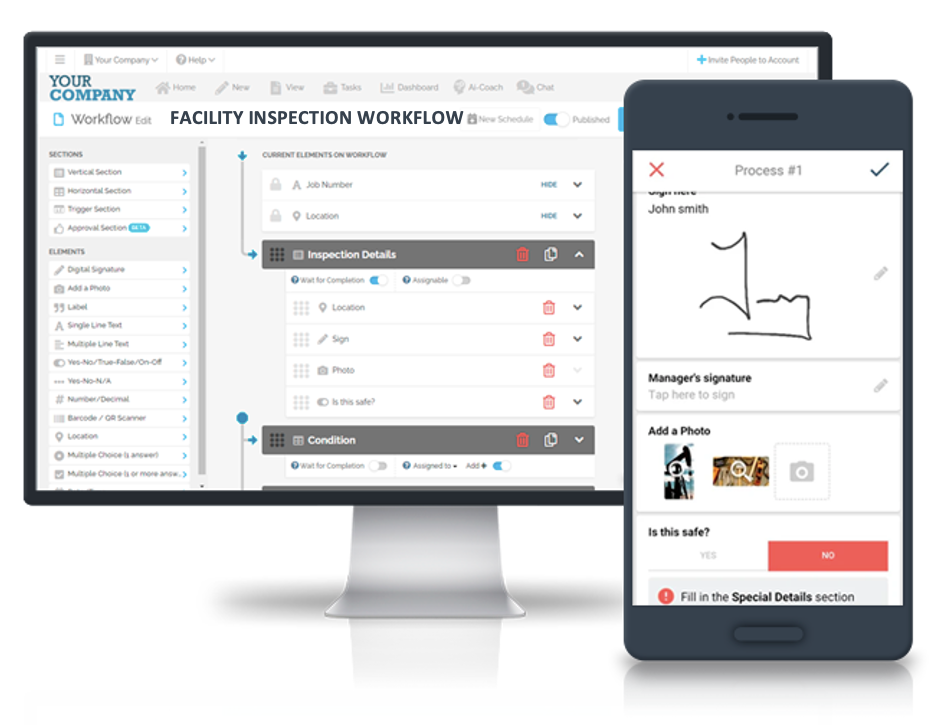

Streamline your checklists, SOPs and inspections with our intuitive workflow solution. Enjoy the ease of dragging & dropping digital procedures onto a platform directly where work is done – plus generate professional reports in an instant. Revolutionize facility inspections quickly without compromising excellence.

Go digital and save big on facility inspection

Tasks such as manual reporting, workforce scheduling, and audits are now automated. Set up recurring tasks to ensure your team is on the same page in minutes – minimizing lost time while maximizing output.

“Being able to capture information during an investigation is BIG”

Sean Seager

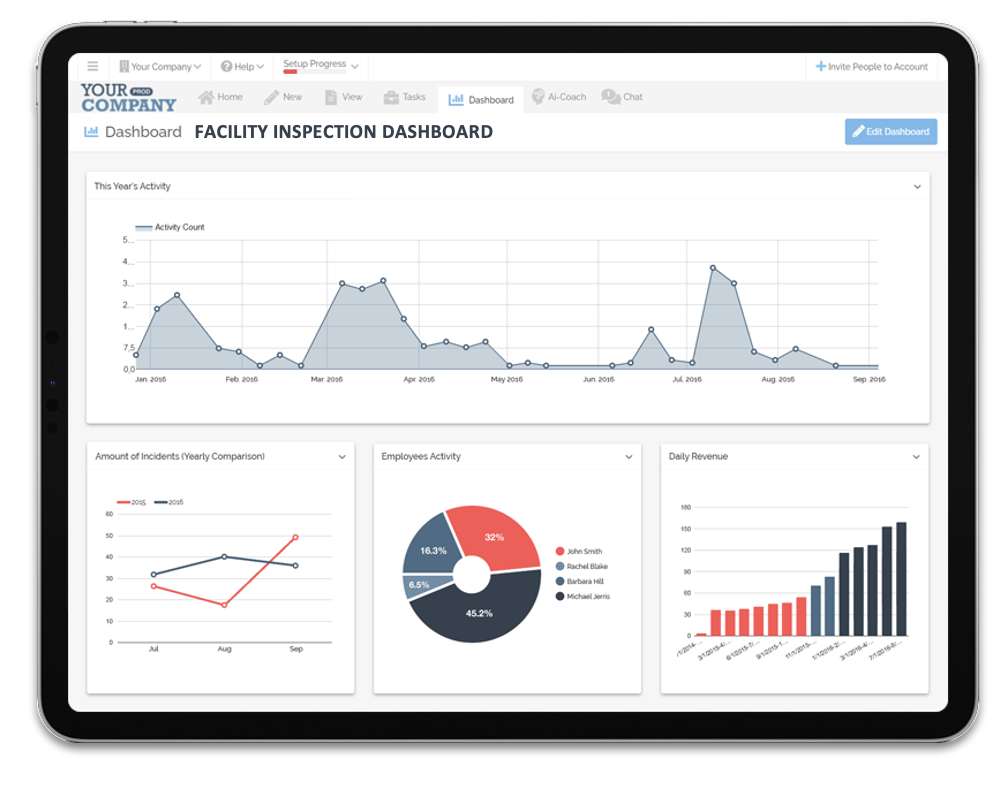

See more and do more

Every single piece of information captured by FAT FINGER users will feed your company analytics in real time. With FAT FINGER, you can see critical facility and production information in a live management dashboard and take action to make decisions that will increase your productivity.

Do more of what matters most

Manage your operations effectively in just a click.

No IT team or code needed, using FAT FINGER is fast and easy.

We empower EVERYONE to initiate and create positive change to streamline the company’s business operations no matter where you are. Automatically assign tasks, send notifications, and simplify any process that requires authorization.

FAT FINGER gets you results in operations

Committed to building sustainable operational excellence platform – trusted by thousand of users across the globe.

56%

Reduced costs

97%

Feel in more control of their operations

7.28hrs

Reclaimed per procedure

84%

Improved quality of output. More data means more actionable insights!

Why Do You Need to Conduct Facility Inspections?

Everyone is responsible for the safety and well-being of those who work in the facilities they oversee. A crucial part of this responsibility is identifying potential hazards and taking steps to mitigate them. Facility inspections are one way to identify potential hazards.

In warehouses and manufacturing facilities, Facility managers can also use inspections to identify areas where there may be risks of forklift accidents or other dangers.

Regular inspections can also help improve communication between managers and workers, as it allows managers to address concerns and answer questions. In addition, inspections can help to identify potential problems before they become serious, saving both time and money in the long run.

Facility inspection in a warehouse typically focuses on safety hazards, such as trip hazards or blocked exits. Facility inspections can also help identify areas where efficiency can be improved, such as streamlining the flow of traffic in a warehouse. Facility inspection in manufacturing, on the other hand, usually focuses on quality control and process optimization.

How Frequently Should You Inspect Your Facility?

The answer depends on the facility type and the risk level. In general, warehouses and manufacturing facilities should be inspected regularly – at least once per month. However, more frequent inspections may be necessary if there are high levels of traffic or hazardous materials present.

By contrast, offices and retail stores typically don’t need to be inspected as often since there is less potential for accidents or damage. At a minimum, these facilities should be inspected once per quarter.

Facility inspections are a critical part of maintaining a safe and functional facility. However, knowing where to start when conducting an inspection can be challenging. Here is an essential checklist of components and areas that should be included in every facility inspection:

Doors and doorways / Floors and floor coverings / Walls and ceilings / Stairs and railings / Windows and window coverings / Electrical outlets and switches / Emergency equipment / Plumbing fixtures

Following a comprehensive inspection checklist can help keep your facility in good condition and avoid costly repairs or downtime.

Take a proactive approach to your facility inspection now

Efficient Facility Inspection with FAT FINGER

Facility inspections are a crucial part of maintaining a safe and functioning environment. Assigning tasks with a paper-based checklist is also often counterproductive, as it can be challenging to track who is responsible for what and when tasks need to be completed. Luckily, there is a better way.

FAT FINGER is a mobile inspection app that helps streamline the facility inspection process and makes it easier to get the job done right. With FAT FINGER, you can create a digital checklist for your facility inspections and assign tasks to specific team members.

With FAT FINGER, you can:

– Make it easy to access and update the checklist as needed, whenever and wherever

-Create a customized workflow that suits your facility inspection needs. Remarks, corrective actions, and photos collected during inspections can be added to your customized workflow.

-The app also includes features such as automatic report generation that you can send to relevant stakeholders via email, PDF, or web link. This way, everyone can stay up-to-date on the latest information.

Make your next facility inspection more efficient and effective by using FAT FINGER! It’s the best way to get the job done quickly and accurately.

About FAT FINGER:

Ensure front-line teams do their work correctly every time. Drag & drop digital procedures that unlock operational excellence.

In seconds anyone can build and deploy enterprise-grade mobile applications using an easy drag-and-drop no-code builder.

FAT FINGER uses machine learning to coach app users in real-time to make safer and improved decisions.

Try building your digital procedure on FAT FINGER for free @ www.fatfinger.io