The Need

A Supermajor Oil & Gas Operator was seeking ways to reduce operational costs & improve production. The project requirements were:

- Cut costs through improved contractor management.

- Improve data in current asset management system to optimize production.

- Reduce safety risk in field operations by standardizing processes.

- Provide a very easy to use mobile app for big finger users, both internal and shared with service providers.

The Solution

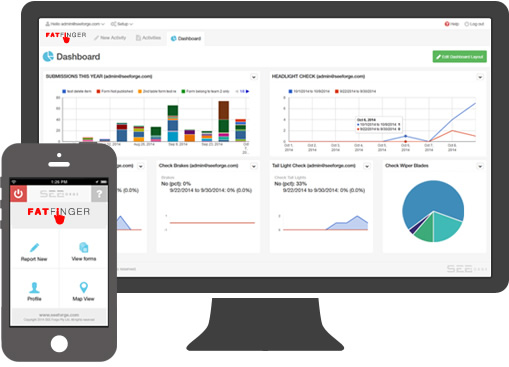

FAT FINGER, by SEE Forge, was selected as an out-of-the-box customer ready solution to improve asset reliability, service provider management and data quality into current asset management systems. They achieved and exceeded their cost reduction goals and users were impressed by how easy the iPhone and Android experience was.

“We see huge value in going digital. The overall feeling is that FAT FINGER was easy to use for everyone, customized to our inspection processes and provided us with new insights to our assets”.

Quote from Asset Reliability Manager – Supermajor Oil & Gas Operator

The Need

A Supermajor Oil & Gas Operator was seeking ways to reduce operational costs & improve production. The project requirements were:

- Cut costs through improved contractor management.

- Improve data in current asset management system to optimize production.

- Reduce safety risk in field operations by standardizing processes.

- Provide a very easy to use mobile app for big finger users, both internal and shared with service providers.

The Solution

FAT FINGER, by SEE Forge, was selected as an out-of-the-box customer ready solution to improve asset reliability, service provider management and data quality into current asset management systems. They achieved and exceeded their cost reduction goals and users were impressed by how easy the iPhone and Android experience was.

“We see huge value in going digital. The overall feeling is that FAT FINGER was easy to use for everyone, customized to our inspection processes and provided us with new insights to our assets”.

Quote from Asset Reliability Manager – Supermajor Oil & Gas Operator

Asset Reliability ManagerSupermajor

Oil & Gas Operator

The Events

The Supermajor Oil & Gas operator is a global leader in onshore and offshore oil exploration and production.

They take safety, environmental and operational excellence seriously and continuously invest into delivering better results for their shareholders.

The reliability team decided to transform their operations from the frustrating and high cost manual paper processes and clunky enterprise systems to a mobile approach with goals of reducing operational costs and improving production collection across their assets.

The Supermajor operational, technology and procurement teams researched the market and selected SEE Forge’s FAT FINGER product to drive improvement in their operations. Starting with the FAT FINGER drag and drop workflow builder, the operator and FAT FINGER success-coaching team collaborated to customize the workflows to match their current business processes.

Big finger and non-technology savvy users were able to quickly understand and start using the FAT FINGER app on their already owned iPhones, iPads, Androids & laptops to complete asset inspection and repair workflows.

The Events

The Supermajor Oil & Gas operator is a global leader in onshore and offshore oil exploration and production.

They take safety, environmental and operational excellence seriously and continuously invest into delivering better results for their shareholders.

The reliability team decided to transform their operations from the frustrating and high cost manual paper processes and clunky enterprise systems to a mobile approach with goals of reducing operational costs and improving production collection across their assets.

The Supermajor operational, technology and procurement teams researched the market and selected SEE Forge’s FAT FINGER product to drive improvement in their operations. Starting with the FAT FINGER drag and drop workflow builder, the operator and FAT FINGER success-coaching team collaborated to customize the workflows to match their current business processes.

Big finger and non-technology savvy users were able to quickly understand and start using the FAT FINGER app on their already owned iPhones, iPads, Androids & laptops to complete asset inspection and repair workflows.

Asset Reliability

Asset reliability improved as field based service providers had access to up-to-date and easy to follow standard operation procedures made available across all digital devices (iPhone, iPad, Android, Desktop). The service providers were able to perform the tasks safely and correctly, ensuring all steps were completed. Rich data such as photos with annotations, GPS longitude/latitude location and quality notes (spell checked & legible) improved the operator’s asset team’s decision-making abilities due to having the data provided in the format they needed and in a timely manner.

Contractor Management & Collaboration

Ensuring that procedures were followed safely, correctly and that clean data was collected reduced friction between all parties. The operator asset team was provided with asset related data as well as real-time activity updates to provide transparency and understanding to where their investment was being spent and what outcomes were being achieved by their service providers. Knowing exactly how much activity was involved to produce a desired outcome provided data for all parties to review and discuss at their contractor review meetings. Ultimately sharing a common tool designed for both parties set appropriate expectations and improved collaboration to produce a better overall outcome.

Asset Reliability

Asset reliability improved as field based service providers had access to up-to-date and easy to follow standard operation procedures made available across all digital devices (iPhone, iPad, Android, Desktop). The service providers were able to perform the tasks safely and correctly, ensuring all steps were completed. Rich data such as photos with annotations, GPS longitude/latitude location and quality notes (spell checked & legible) improved the operator’s asset team’s decision-making abilities due to having the data provided in the format they needed and in a timely manner.

Contractor Management & Collaboration

Ensuring that procedures were followed safely, correctly and that clean data was collected reduced friction between all parties. The operator asset team was provided with asset related data as well as real-time activity updates to provide transparency and understanding to where their investment was being spent and what outcomes were being achieved by their service providers. Knowing exactly how much activity was involved to produce a desired outcome provided data for all parties to review and discuss at their contractor review meetings. Ultimately sharing a common tool designed for both parties set appropriate expectations and improved collaboration to produce a better overall outcome.

BUSINESS VALUE

| Business Process | Benefit | Business Value |

|---|---|---|

| Asset Inspection | Asset Reliability Reliability team provided with early warning system to problems with their assets |

Millions in reduced operational & admin costs |

| Real-time visibility of asset data | Millions in improved production revenue from improved asset uptime | |

| Improved data quality in asset management system | ||

| Asset Inspection | Contractor Management Reduced tension and improved working relationship between all parties |

Improved service provider effectiveness and efficiency |

| Improved safety performance through task standardization | Reduced service provider overcharges |