Mobile Asset Inspection

Inspect, maintain, and manage your assets at your fingertips with digital workflow.

Trusted by companies all over the world

Before FAT FINGER

Frequent equipment breakdown

Unmonitored machine parameters can lead to erroneous readings, resulting in low productivity and unexpected breakdowns

High operational costs

Without the help of modern technology, more time is spent on paperwork and longer delays in production cost more to correct.

Increase production capacity like never before

FAT FINGER is the essential asset manager on the go. Our intuitive workflow allows you to keep your equipment performing optimally with drag & drop digital procedure and easy scheduling control. Streamline maintenance tasks so you can spend more time doing what matters most – getting work done.

Unlock new operational savings with the power of digital workflow

Cut out tedious tasks and boost your team’s productivity with automated field reporting, workforce scheduling, and invoicing. Set up recurring projects in no time – giving everyone the same page from start to finish so you can focus on getting results!

“Gives people information right away, in real time. And provides transparency across the organization.”

Laurie Campbell

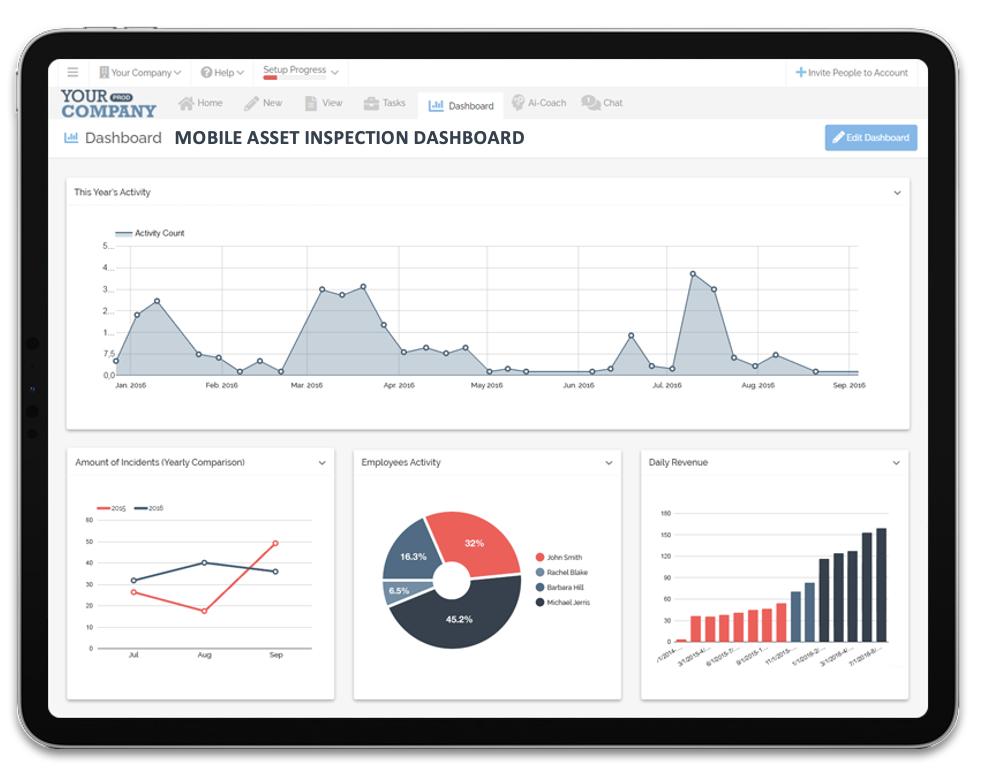

Achieve operational excellence through real-time, data-driven insights

Having access to the right asset data on each piece of equipment helps in anticipating maintenance so you can plan accordingly. Do integrations your way by connecting FAT FINGER into any system with our open API. Collect maintenance data on demand and make smarter decisions.

Change the way you work

Transition a world of reactive maintenance tasks into a centralized asset management platform.

FAT FINGER gets you results in maintenance

Committed to improving the way organizations manage their maintenance operations – trusted by thousand of users across the globe

31%

Saved in maintenance cost

97%

Feel in more control of their assets

38.75hrs

Reclaimed per week performing maintenance

84%

Improved overall equipment effectiveness. More data means more actionable insights!

Mobile asset inspection is a process used to identify potential safety and reliability issues with industrial equipment.

In 2020, the rate of job-related injuries and illnesses in the oil and gas industry in the United States was 1.4 per 100 workers (Sönnichsen, 2022).In terms of cost, when a sizeable onshore facility unexpectedly goes offline because of maintenance issues, it costs an estimated $7 million a day in lost revenue, which is far more for offshore industries (Why Oil and Gas Companies Must Focus on Asset Maintenance. Eoncoat, 2019).

Other potential problems that can be identified include poor maintenance, lack of safety training, and a thorough understanding of operational excellence. This is where mobile asset inspection comes in. By using mobile devices to inspect the equipment, these potential problems can be quickly identified and dealt with before they cause any accidents or significant issues.

Benefits of Mobile Asset Inspection

When it comes to industrial operations, maintenance of equipment is crucial for a variety of reasons, especially in oil and gas due to the volatile and dangerous nature of the work. As a result, mobile asset inspection has the potential to:

– Create a safer working environment.Mobile asset inspection can help to identify potential safety hazards, which can be addressed before they lead to accidents or injuries.

– Improve efficiency.Mobile asset inspection can also help improve operations’ efficiency by identifying issues that may be slowing down production.

– Enhance asset reliability.Mobile asset inspection can also help improve equipment’s reliability by identifying and addressing issues that may cause it to fail.

– Improve understanding of operational excellence.Mobile asset inspection can help companies identify areas where they can improve their operations and ensure that they are running as smoothly and efficiently as possible.

Mobile asset inspection software is a valuable tool that can be used to improve overall safety and reliability in the oil industry. One of which, FAT FINGER, has been 97% percent effective at giving users more control over their operations.

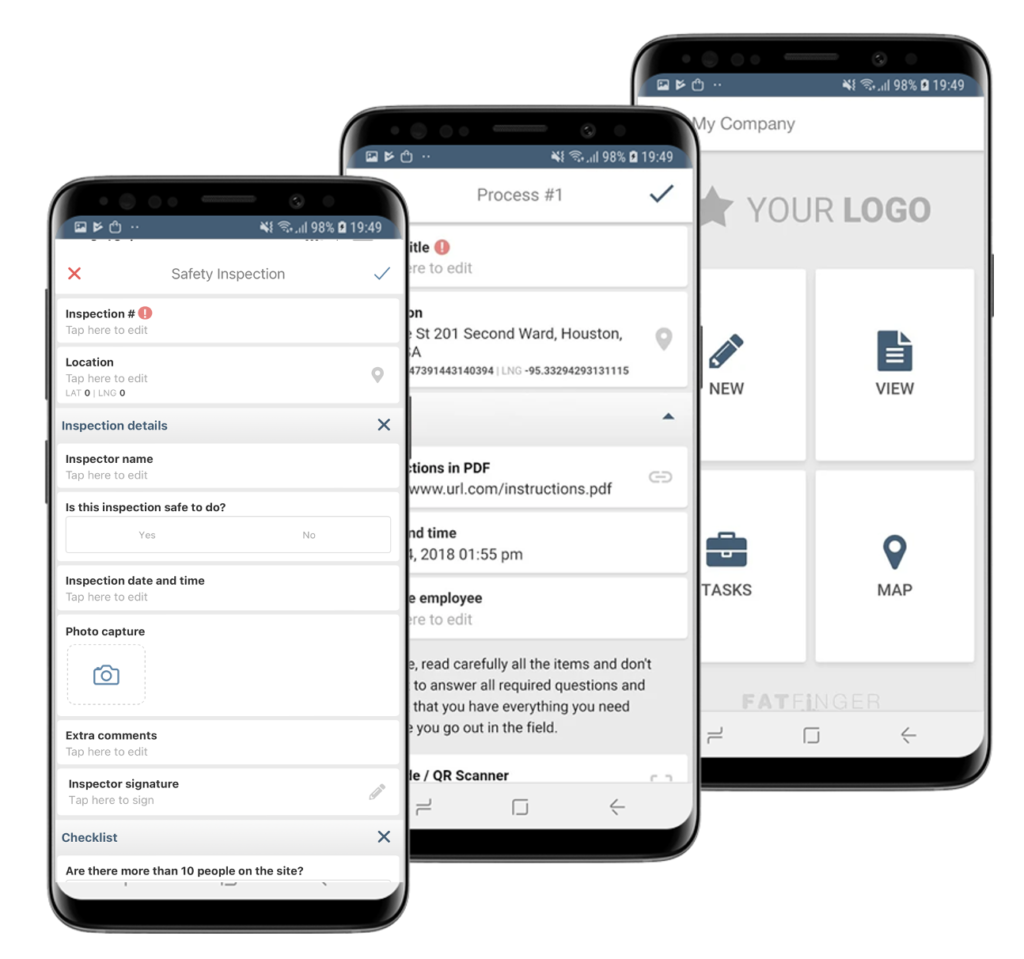

Asset inspection, anytime and anywhere

Transition a world of reactive maintenance tasks into a centralized asset management platform.

Fat Finger and Its Engineering Wonders

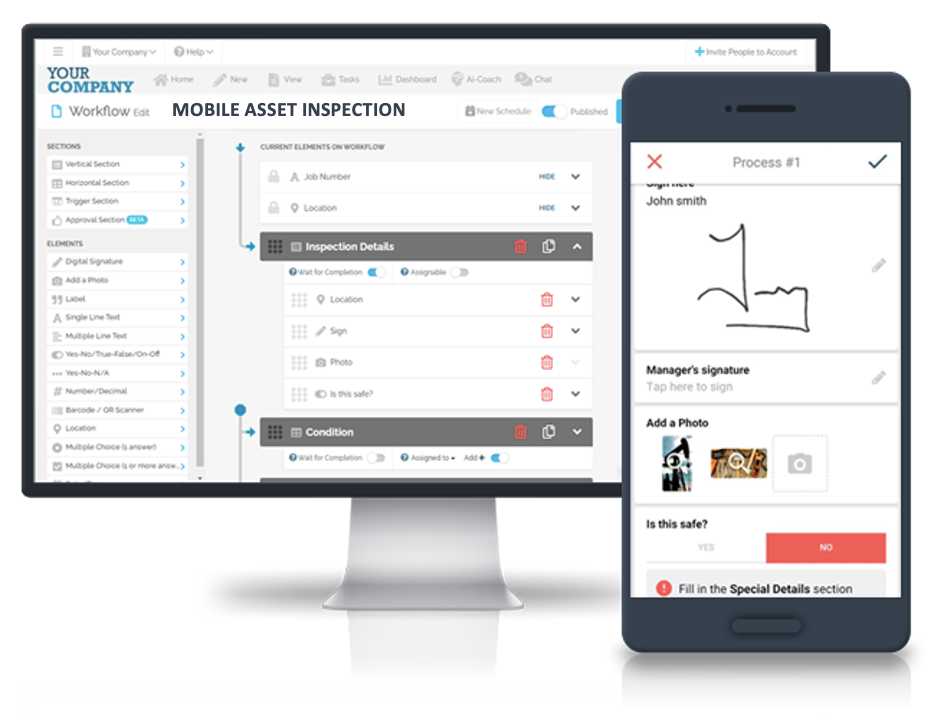

Fat Finger is a powerful and intuitive mobile inspection software that can build enterprise grade procedures in seconds- without the need for hours of tedious work. Moreover, its features include:

-Smart Procedures via Drag & Drop

-Offline Mobile Data Capture

-Workflow that streamline your processes

-Artificial Intelligence Insight and Analysis

-1 Click Reporting & Export

-Integrations to push and pull data in real-time

Since the oil and gas industry is incredibly complex, it can be challenging to keep track of all the different procedures and processes. Without a streamlined process, things can quickly go wrong in this industry. Mistakes can lead to accidents, loss of money, and even loss of life.

FAT FINGER was created to help drive operational excellence in the oil and gas industry. Our digital procedures make it easy to follow the correct process for every task, no matter how complex. Imagine improving your business processes with just a few clicks of your fingertip- that’s what Fat Finger can do for you. This platform is designed specifically for the oil and gas industries, so you know you’re getting the best possible service.

Power up your safety and reliability by signing up today for a free trial of FAT FINGER.

About FAT FINGER:

Ensure front-line teams do their work correctly every time. Drag & drop digital procedures that unlock operational excellence.

In seconds anyone can build and deploy enterprise-grade mobile applications using an easy drag-and-drop no-code builder.

FAT FINGER uses machine learning to coach app users in real-time to make safer and improved decisions.

Try building your digital procedure on FAT FINGER for free @ www.fatfinger.io