Maintaining a certain level of quality in the products or services offered in any industry is essential. This is especially true for companies that produce goods sent out to be sold to the public.

One of the vital tools for quality control is a checklist. This article discusses what a quality control checklist is and how important it is in quality control inspection.

Table of Contents:

I. What are Quality Control Inspections and their Objectives?

II. Quality Control Vs. Quality Inspection

III. What are Quality Control checklists and their Applications?

IV. 6 Steps to Create an Effective Quality Control Checklist

V. Why do Industries Need an Effective Quality Control Checklist?

VI. Quality Control Checklist with FAT FINGER

What are Quality Control Inspections and Their Objectives?

Quality control inspection is a process used to assess the quality of products or services.

The main objective of quality control inspection is to identify defects or errors to correct them before the product or service is delivered to the customer.

Quality control inspection can be performed at various stages of production, including during the manufacturing process, before delivery, and after installation.

Quality control inspection typically involves checking for compliance with specifications, comparing products or services to standards, and testing for functionality.

Quality Control Vs. Quality Inspection

Quality control and quality inspection are terms often used interchangeably, but they actually refer to two different aspects of quality assurance.

Quality control focuses on preventing defects from occurring in the first place, while a quality inspection is focused on identifying and correcting defects that have already happened. Quality control is typically carried out by the manufacturing team during the production process, while a separate group of inspectors usually performs the quality inspection.

Quality control methods can include operator training and proactive maintenance, while quality inspection methods often involve 100% inspection or sampling inspection.

Both quality control and quality inspection are essential for ensuring that products meet high standards, but they play different roles in the overall process. A checklist is often used as a quality control tool to ensure that all steps in the process are followed and that the product meets all specifications.

What are Quality Control Checklists and their Application?

A quality control checklist is a document that contains a list of Quality Control checks that need to be carried out at different stages of the manufacturing process. The checklist helps to ensure that all Quality Control checks are carried out and that products meet the required standards. Quality Control checks can include tests, inspections, and audits.

Quality control checklists can be used in various industries, from oil and gas manufacturing to food production. They must be tailored to the specific product and process to be effective. Quality control checklists are essential for ensuring that products meet the highest possible quality and performance standards.

6 Steps to Create an Effective Quality Control Checklist

Quality control is essential for any manufacturing or production process. Implementing a quality control inspection checklist can help ensure that your products meet the highest quality standards. Here are the steps to creating a quality control inspection checklist:

1. Identify the specific Quality Control criteria that you will be assessing.

This will vary depending on the type of product you are manufacturing. For example, in the Oil and Gas Industry, quality control measures are implemented to test the characteristic of heavy fuel oil to see if it meets the standard. In food manufacturing, quality control might involve checking the quality of raw materials, testing products for contaminants, and assessing packaging quality.

2. Once you have identified the specific Quality Control criteria, you need to decide how you will measure compliance. This will usually involve some form of testing or inspection.

3. Develop a checklist that includes all of the Quality Control criteria you will be assessing. It may consist of the physical and chemical properties of the product, as well as how the product performs under different conditions.

4. Once you have identified the Quality Control criteria and potential defects, you can start creating your quality control inspection checklist. This should include a detailed description of each Quality Control criterion and specific instructions for checking for defects.

5. Test your Quality Control inspection checklist before using it on actual products. This will help ensure it is effective and catches any potential defects.

6. Implement your Quality Control inspection checklist in your manufacturing process. This will help ensure that all your products meet the highest quality standards.

Why do Industries Need an Effective Quality Control Checklist?

Quality control is critical for any industry that wants to produce products that meet customer expectations. An effective quality control checklist will cover all aspects of the product development process.

By having a practical quality control checklist, industries can improve their products’ quality and ensure customer satisfaction. Quality Control Checklists are vital because it:

- Ensures that products meet customer expectations by verifying that the product development process is followed correctly.

- Can identify potential problems early on in the process before they result in defects or customer complaints.

- Allows industries to track progress towards meeting quality goals.

In short, Quality Control Checklists exist to improve Quality Standards throughout the industry by providing a systemized method of identifying & correcting errors along every step of production – from design to delivery.

An industry-wide move towards higher quality standards means better products for consumers and increased efficiency & productivity for manufacturers – so make sure your business is ahead of the curve by implementing an effective Quality Control Checklist today.

Quality Control Checklist with FAT FINGER

Integrating quality management into your business process can proactively catch product defects and prevent them from affecting the consumers and your organization’s hard-earned reputation.

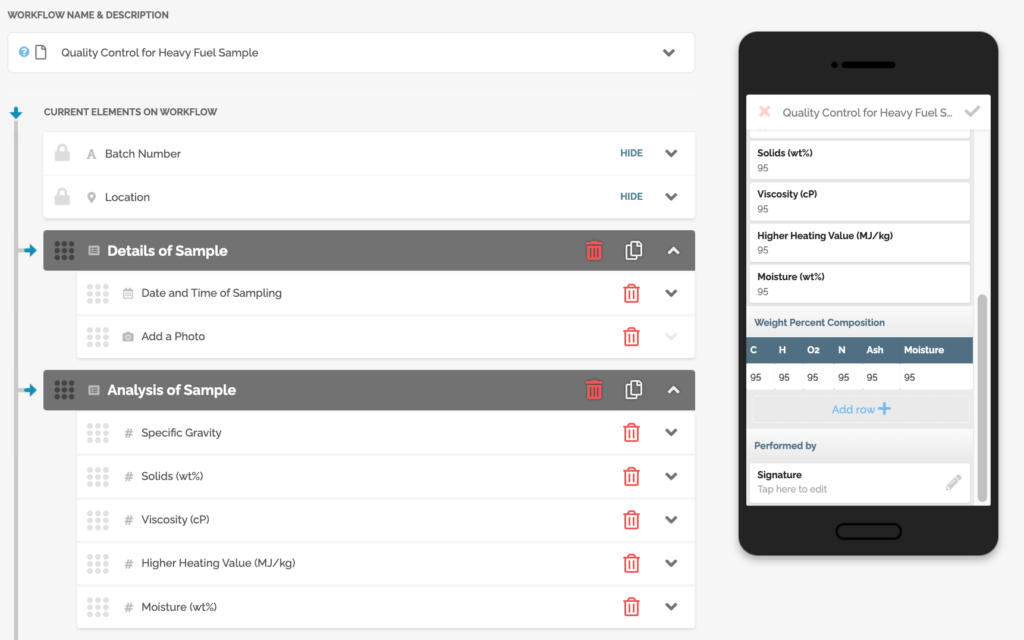

FAT FINGER Quality Control Checklist is a free, customizable digital checklist that the industry can use to help prevent insufficient data and poor-quality reports. It also contributes to avoiding poor decision-making capability, double entry, and manual tasks that can lead to manufacturing quality risks.

The digital checklist helps you to attach photos while conducting complete quality audits and inspections to ensure continuous improvement.

It also enables businesses to utilize quality-related forms and checklists and to find other templates that may be relevant to their business in the FAT FINGER Public Library.

Implementing a quality control checklist with FAT FINGER into your business process is an intelligent way to keep your product quality high and your manufacturing risks low.

Check out our video below on how FAT FINGER works, and see how easy our quality management software provides the tools you need to streamline your quality control processes and improve product quality.

You’ve probably heard that quality is key, but what does that mean for your industry?

It’s hard enough to stay on top of quality control without worrying about the tools you’re using. And if you don’t have the right tools, you can’t even begin to think about improving your process.

FAT FINGER is here to help. We offer a suite of quality-related forms and checklists, as well as customizable audits and inspection workflow so that you can ensure continuous product improvement.

Plus, our photo-based evidence attachment during inspections feature makes it easy to keep track of everything that’s happening in your factory.

And if that wasn’t enough, our cloud-based system means you can access our mobile checklist wherever and whenever.