The global workflow management system market was valued at $4.8 billion in 2018. This figure is anticipated to rise with a compound annual growth rate (CAGR) of 27.7% from 2019 to 2025.

One reason for this tremendous growth is the digital transformation of businesses globally. This transformation is called industry 4.0.

The workflow management systems market encompasses workflow software. Workflow software helps businesses digitize their operations to create lean and efficient procedures. In this vein, workflow software comes as a vital tool for organizations in our new, digital age.

In this article, you’ll understand what workflow software is and its importance for businesses operating in industry 4.0. The article is structured as follows:

- What is workflow software?

- Why you need to take control of your business workflows

- How SpaceX used workflow management solutions to launch 100 rockets into space

- 4 actions you need to execute before applying workflow software

With that said, let’s jump to it!

What is workflow software?

Workflow software is a business management application designed to help organizations document, monitor, and optimize their business workflows.

What is workflow?

A workflow is a series of tasks that, when executed in a specific order, contribute to the delivery of a desired output.

Workflow software allows you to:

- Define each task in a workflow

- Detail who is responsible for that task

- Document when the task is due

- Link multiple workflows for smooth synchronized operations

To exemplify what we mean by a workflow, let’s take the creation of this article as an example.

I write the first draft and then pass the document through several stages before the final publication. The content passes from the writer to the editors. The editors then review and approve the content. Finally, the proofreader checks for copy errors and passes the article to the production team (e.g. graphic designers). The content is then published. This is a workflow.

As you can tell, for each stage of the workflow individuals have their specific roles. There’s the writer, editor, proofreader, and graphic designer. Once each person has completed their assigned task, the person responsible for the next stage is notified.

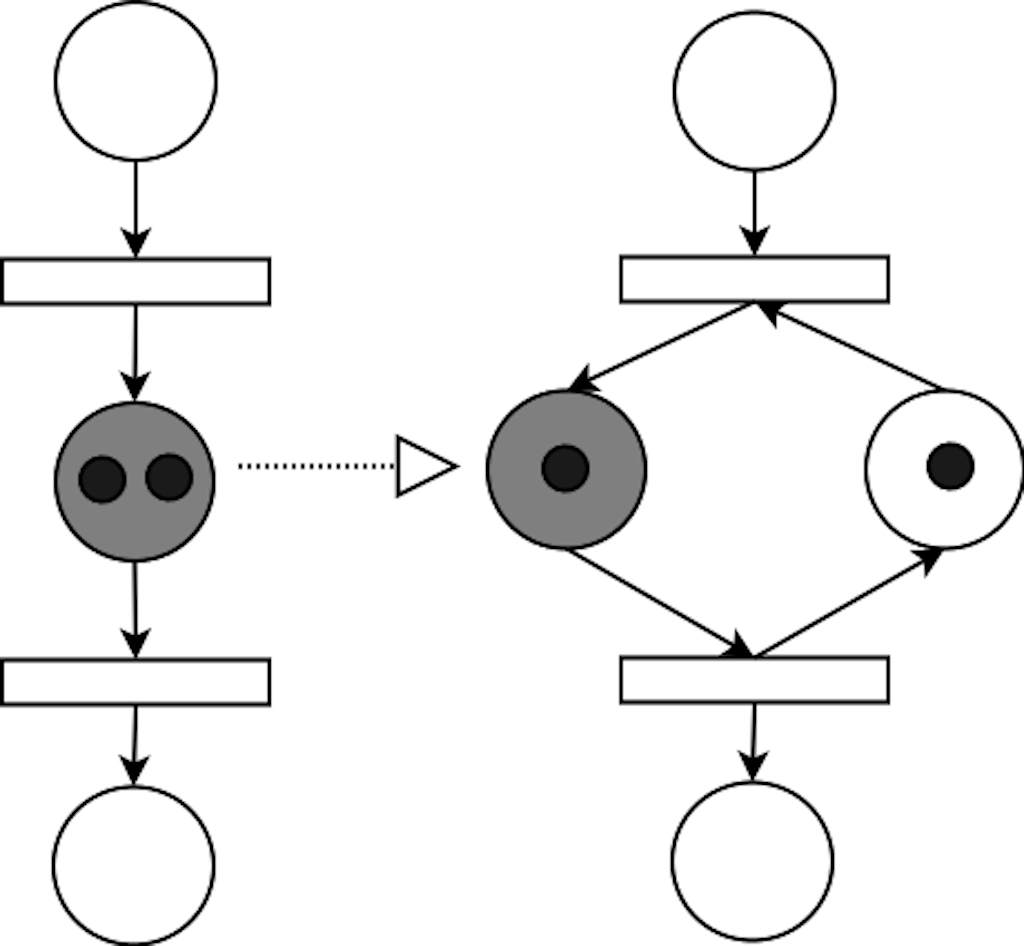

The underlying framework to workflow management

Workflow management stems from a mathematical concept called the Petri Net, otherwise known as place/transition (PT) net. A Petri Net takes a series of tasks that make up a workflow, and represents these tasks in a graphical notation. Choices are represented by circles and interactions are represented by arrows.

Workflow management is based on this approach. Each workflow model displays tasks as nodes and dependencies between the nodes. Tasks are activated when the dependency between conditions is favored.

Workflow software takes the above concepts to create a user-friendly, and actionable tool. This allows businesses to document and control their workflows.

Why you need to take control of your business workflows

Workflow software has emerged as a solution for enterprise digital transformation. This transformation is dubbed industry 4.0, characterized by the establishment of the Internet of Things (IoT), SaaS as a service, artificial intelligence (AI), and big data.

Industry 4.0 represents a new phase in business, one that focuses on interconnectivity, automation, machine learning, and real-time data to create a holistic, and more connected business environment.

- The first industrial revolution: This revolution happened between the 1700s and 1800s. The steam-powered engine was the flagship of this era.

- The second industrial revolution: Occurred in the early part of the 20th century. Here we have electricity used to increase efficiency and to help make factory machines more reliable.

- The third industrial revolution: Computer technology came to the scene. Over time, there was a change to put less focus on analog and machine technology, and more focus on digital technology and automation software.

- The fourth industrial revolution (industry 4.0): In the past few decades, industry 4.0 has emerged. The physical is connected with the digital, to allow for better collaboration, and access across departments, partners, vendors, products, and people. Workflow software is a tool of industry 4.0.

Workflow software is leading the front of industry 4.0. The benefits workflow software brings is contributing to a substantial market growth in workflow management software globally. I’ve listed the main benefits to using workflow software below.

Workflow software increases business interconnectivity

Workflow software gives businesses the means to map their operations, pooling information and data on how work happens in one platform. This gives transparency regarding work done by all teams, people, and departments.

Workflows require collaboration between multiple teams. Plus a given workflow is rarely run in isolation. That is, one workflow will feed information into another, and operate in synchrony with multiple different workflows. Workflow software gives the means to document this connectivity between people, departments, and different business systems.

Workflow software enables automation

McKinsey and Company estimated that 45% of current paid activities can be automated using today’s technology, which is equal to $2 trillion in total annual wages.

Workflow software means old paper-based processes are digitized. With this digitization comes automation. Checking a task, entering data into a workflow form field, or any other user action can be used as a trigger signal for automation. Data from the workflow is transferred as per your instructions. This hands-off approach helps streamline repetitive and time-consuming work.

Take FAT FINGER for example. FAT FINGER is workflow software that enables you to document business procedures and workflows in seconds. The software features give you the means to instantly automate key processes and integrate with existing systems.

It’s possible to integrate machine learning with workflow management

Machine learning is the development of computer systems that can use real-time data to adapt and learn without following explicit instructions.

Machine learning is possible by drawing algorithms and statistical models that analyze and draw inferences from patterns in data.

Research shows it’s possible to apply the techniques from machine learning to workflow management systems. This creates adaptable and automatic process control, and is something that’s used by Amazon.

As you know, Amazon is an online powerhouse that’s stormed through the retail industry providing everything from books, to furniture, to gadgets – you name it, and Amazon probably sells it.

Yet to be great at pretty much everything, you need to have efficient workflows. Furthermore, these workflows need to be self-correcting, using machine learning and AI every second data is imputed.

Amazon uses AI and machine learning to improve its operations. As David Alperson, Director of logistics at Amazon says:

“With the millions of items that we ship, every opportunity to improve a process by a second is relevant”

David Alperson, Vice President, Amazon Logistics, Amazon This Company built one of the world’s most efficient warehouses by embracing chaos

Workflow software uses real-time data

When a workflow is run, real-time data is documented.

Let’s say you want to run a risk assessment, an ISO audit, or create an invoice – whatever your goal, all you have to do is open your specific documented workflow and complete each step.

As you go you’ll enter data specific to your workflow run query. This data is imputed in real-time and hence your workflow acts as a data storage system.

By helping organizations use industry 4.0 principles, workflow software supports a digital transformation, which brings benefits for businesses, as outlined by K.M. and H.R Wilburn. Industry 4.0 means:

- Businesses can do more with less.

- Manual labor is removed meaning fewer workers and hence employee expenses.

- Time from product idea to product creation is reduced.

- Automation is employed cutting costs and removing time wasted.

The direct benefits of workflow software

On top of being industry 4.0 compliant, workflow software gives more direct benefits worth noting.

Keeping it brief, listed below are the direct benefits that workflow software brings:

Near-term benefits:

- Accountability: Workflow software gives employees a centralized view of all current and upcoming assignments. Uncompleted tasks can be followed up in a timely fashion.

- Continuous improvement: Redundant tasks and workflow bottlenecks are identified, and repetitive tasks are automated.

- Big picture thinking: Connected workflows can be viewed as a network, giving managers a big picture view of business operations.

Long-term benefits:

- Less human error: Following a workflow means executing the step-by-step instructions needed to deliver the required output. Workflows provide the information on how to perform a given step. This removes the likelihood of human error.

- Process flexibility: Want to update your standard practices? No problem. Workflow software allows you to digitally update your relevant workflows in seconds. This gives a streamlined way of communicating changes on a team-wide level.

- A culture of accountability and transparency: With workflow software, you can see who is assigned to what task, how much of that task they’ve completed, and what they have to do to complete that given task.

How SpaceX used workflow management solutions to launch 100 rockets into space

SpaceX designs, manufactures and launches advanced rockets and spacecrafts. SpaceX made it their mission to launch a rocket into space every two weeks. This was a high bar to set until their optimized workflows finally launched them towards their goals.

In their quest to increase accessibility to space, SpaceX strived to optimize the use of automation, workflow-flow and communication. This meant the human operator could focus on decision-making tasks.

This optimization helped SpaceX master their supply lines, in-house production, and engine testing. In 2020 alone, SpaceX launched 26 rockets including their 100th successful space mission.

In conclusion workflow management helped SpaceX operate on a refined system with well-designed workflows and automation.

Workflow software solutions, such as FAT FINGER, makes it easy for you to manage and optimize your business workflows, just as SpaceX does.

4 actions you need to execute before applying workflow software

Before you apply workflow software, there are a few things you’ll need to figure out. I’ve detailed these as action items, and listed them below.

Action item #1: Evaluate the existing system

You need to understand how everything in your business works. All managers and subject matter experts must be involved in this stage. Ask your teams and departments what vital elements need to be included in your workflow. Also, think about strategy adjustments and how your workflow should represent these.

FAT FINGER offers an easy drag-and-drop approach to help you build out your business operations quickly and effortlessly. Document your workflows using FAT FINGER to evaluate your existing systems.

For more information on how you can document your business workflows, check out the following FAT FINGER articles:

- Swimlane Diagram: How to Complete Multi-Departmental Processes Without Chaos & Confusion

- Process Design: What It Is, Why You Need It, & How To Get It Right

Action item #2: Identify your workflow challenge

Once you understand how your business works, you then need to consider how you can improve on this. Take the time to dig deep and find out your specific pain points. Apply process improvement models to optimize your workflows.

For more information on how to optimize your business workflows, check out the following articles:

- Muda: What It Is & How to Easily Remove Waste In Essential Processes

- Kaizen Event: How to Go About Continuous Business Improvement Like a Pro

- Time = Money, How to Save Both with Workflow Analysis

Action item #3: Take a test drive

Approach employees who will be using your newly designed and optimized workflows day-in, day-out. Ask them about their requirements.

Then, run 5 mock instances that take different paths of your newly designed and optimized workflow. Even if this takes a few hours it’s worth it. Gather feedback and find out if your optimized way of doing things is optimized.

Action item #4: Determine your metrics for success

How will you know if your workflow is operating properly without having a comprehensive plan to measure performance?

Establish a metrics system that allows management to quickly and efficiently monitor performance across divisions. Compare metric measures to measures from your old processes as a baseline to decipher improvements.

Choose the right workflow software and start optimizing your business processes

Workflow software allows you to easily take control of your business operations, manage and optimize them. This brings substantial benefits to business, allowing organizations to lead a digital transformation in response to a new industry, industry 4.0.

Yet, despite the plethora of benefits workflow software brings, you must choose the right software to suit your needs.

If you’re looking for a no-code solution to your workflow woes, then FAT FINGER is the tool for you. For more information on all of FAT FINGER’s workflow management abilities, check out the video below.

Once more, at FAT FINGER we have over 100,00 free templates detailing already optimized workflows and best practices for common business activities.

From running a Marketing Audit to Safety Inspection checklists – you name it, we have it. And if we don’t, then you can easily document any workflow to add to your workflow library.

First, signup to your free FAT FINGER account, browse our extensive workflow library and start optimizing your business workflows today.