Food safety is a critical part of running any food service operation. From ensuring that food is properly stored and handled to preventing the spread of bacteria, food safety protocols are essential for minimizing risk and protecting your business.

Fortunately, implementing effective food safety SOPs need not be a daunting task. By following some simple steps, you can create a food safety program that meets your specific needs and helps keep your kitchen running safely and smoothly.

Table of Contents:

I. What are Food Safety SOPs and Why are They Important

II. 5 Steps on How to Customize Food Safety SOPs

III. Benefits of digital workflow in Food Safety SOPS

What are Food Safety SOPs and Why are They Important

Food safety SOPs are standard operating procedures that food businesses use to ensure food is safe for consumption. SOPs cover all aspects of food safety, from food handling and preparation to storage and transportation.

They are an important part of any food business’s operations, as they help to minimize the risk of food contamination and foodborne illness.

Effective food safety SOPs must be tailored to the specific needs of the business and should be regularly reviewed and updated as necessary. They should be easily accessible to all staff and should be followed diligently at all times.

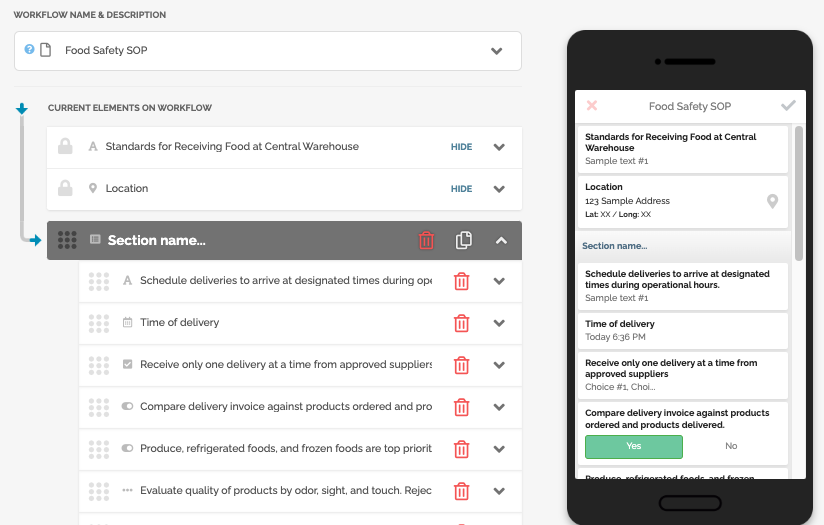

Digital workflow management systems like FAT FINGER can be a valuable tool in helping businesses to develop and maintain effective food safety SOPs, by providing a centralized repository for all SOPs and supporting documentation. By using a digital workflow management system, food businesses can help to ensure their SOPs are always up-to-date and compliant with current food safety regulations.

5 Steps on How to Customize Food Safety SOPs

Food safety is a serious issue in the food industry. No one wants to get sick from eating at their establishment, and there are a lot of foodborne illnesses that can be easily prevented with proper food safety procedures. Each year, foodborne illness sickens millions of people and costs the industry billions of dollars.

While there are much different food safety SOPs (standard operating procedures) that you can implement in your food manufacturing site or restaurant, it’s important to customize them to fit your specific needs.

Otherwise, you might find that your staff isn’t following the procedures correctly, or that they’re not effective in preventing foodborne illnesses. Here are a few tips on how to customize food safety SOPs:

1. Identify the food safety hazards that are specific to your site.

This could include things like cross-contamination, food storage temperatures, and food handling procedures. There are a lot of food safety hazards to consider, so it’s important to narrow down the list to the ones that are most relevant to your food manufacturing site.

This can be done by conducting a hazard analysis. Once you have identified the hazards, you can develop policies and procedures to address them. For example, if you are concerned about cross-contamination, you might implement a policy that requires food items to be cooked in a certain order.

2. Research the best food safety practices that fit your need.

To ensure that your food safety procedures are up to par, it is important to customize them to fit the specific needs of your food manufacturing site or restaurant. While there are many different ways to do this, here are a few key considerations:

– The type of food you serve: Certain foods are more likely to harbor bacteria and other contaminants than others. For example, raw meat and poultry are especially susceptible to foodborne illness. As such, it is important to have strict food safety procedures in place if you serve these items.

– The size of your operation: The larger your manufacturing site, the more complex your food safety procedures will need to be. This is because there is a greater risk of contamination when food is prepared in large quantities.

– Your location: If your manufacturing site is located in an area with a high risk of foodborne illness (such as close to farms or food processing facilities), you will need to take extra precautions to protect your customers.

By taking into account these factors, you can develop food safety procedures that are tailored to the unique needs of your manufacturing site. This will help you keep your customers safe and improve the overall quality of your food operation.

3. Write down the food safety procedures that you want your staff to follow.

Be as specific as possible, and make sure to include all of the steps that need to be taken for each hazard.

The following are some of the food safety procedures that are in a food manufacturing site:

– Wash hands thoroughly with soap and water before handling food.

– Keep food preparation surfaces clean and free of contaminants.

– Cook food thoroughly to kill any bacteria or other contaminants.

– Avoid cross-contamination by keeping raw food separate from cooked food.

– Store food at proper temperatures to prevent bacteria from growing.

– Use clean utensils and serve dishes when serving food.

– Discard any food that has been contaminated or that is past its expiration date.

By following these simple food safety procedures, we can ensure that our food is safe to eat and that our customers are satisfied.

4. Train your staff on the new food safety procedures, and make sure they understand why these procedures are important.

Give them time to ask questions and raise any concerns they have.

Your staff must be properly trained on the food safety procedures that you have put in place. They need to understand not only what to do, but also why these procedures are important. For example, they should know that food needs to be cooked to a certain temperature to kill bacteria.

Your staff must be properly trained on the food safety procedures that you have put in place. They need to understand not only what to do, but also why these procedures are important. For example, they should know that food needs to be cooked to a certain temperature to kill bacteria.

We all know that having good procedures in place is key to running a smooth food manufacturing operation, but it’s hard to get everyone on the same page and keep things organized. Without clear procedures in place, employees can often become confused about what they’re supposed to do and how they’re supposed to do it. This can lead to mistakes and decreased efficiency.

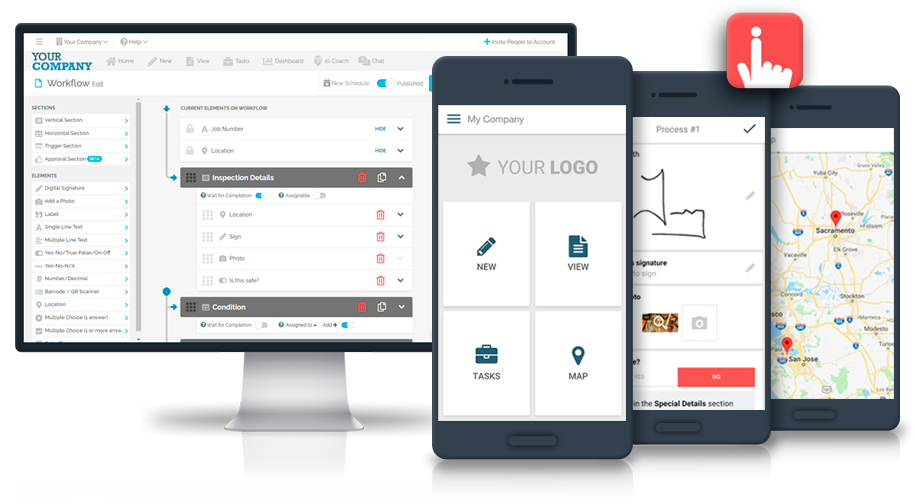

FAT FINGER is the solution you need. Our workflow app will help you capture and standardize knowledge, clearly communicate standards and how-to’s, automate workflows, and identify key areas for improvement. With FAT FINGER, you’ll be able to run a smooth, efficient operation every time.

5. Implement the new food safety procedures on your site, and monitor them closely to ensure they are being followed correctly.

To ensure the food safety procedures are being correctly implemented in your manufacturing site, you will need to closely monitor the process.

One of the best ways is to create a digital workflow that can be easily followed by all employees wherever they are. This should include detailed instructions on how to handle food such as food temperatures and storage times, as well as what to do in the event of a foodborne illness outbreak. This workflow should include all steps from food preparation to serving and should be updated regularly as new information becomes available.

Once the workflow is in place, you will need to train all employees on the new procedures and make sure they understand the importance of following them correctly. You will need to monitor the process closely to ensure that everyone is adhering to the new procedures.

A digital workflow can also help you quickly and easily update your SOPs as new information becomes available. This will help ensure that your manufacturing site is always up-to-date with the latest food safety guidelines.

Benefits of Digital Workflow in Food Safety SOPS

Maintaining a food safety protocol is essential for any food-related business. However, implementing and following these procedures can be difficult, especially for businesses that are short-staffed or have limited resources. That’s where a digital workflow can come in handy.

There are many benefits of using a digital workflow in food safety SOPs, including:

-Improved communication between employees and reduced mistakes.

By having all the necessary information at their fingertips, employees will be able to work more efficiently and effectively together.

– Easier to follow instructions.

– Can be accessed anywhere in the manufacturing site or restaurant since it is on the app.

– Helps reduce foodborne illness outbreaks.

This is by creating detailed instructions on how to prepare food, store it, and serve it safely depending on your preference.

The bottom line: A digital workflow is an essential tool for any food-related business looking to maintain a safe and healthy environment for customers and employees alike.

Digital food safety workflows are becoming increasingly important as the food industry strives to maintain high standards of food safety. One digital workflow tool that is reliable in the market is FAT FINGER.

FAT FINGER is a food safety application that helps food businesses to standardize and streamline their food safety SOPs (standard operating procedures).

The application provides a centralized platform for storing and managing food safety SOPs, as well as a variety of features to help businesses automate and improve their food safety compliance.

For example, FAT FINGER can be used to create and track food safety audits, generate automatic reminders for food safety tasks, and create digital forms and checklists for food safety inspections.

In addition, FAT FINGER integrates with other software applications to provide a complete digital solution for food businesses. By using FAT FINGER, food businesses can improve their food safety compliance while reducing costs and increasing efficiency.

If you’re looking to improve the food safety procedures on your site, consider implementing a digital workflow. It could make all the difference in keeping your customers and employees safe.

Are you looking for a better way to manage your food safety SOPs?

FAT FINGER understands the importance of streamlining and automating food safety compliance. Our software provides a variety of features to help businesses automate their food safety processes, making it easier and more efficient than ever before.

With FAT FINGER, you can rest assured that your food safety SOPs are standardized and up-to-date. You’ll have a centralized platform for storing and managing your SOPs, as well as a variety of features to help you automate your food safety compliance. So why wait? Sign up for a free trial today!

About FAT FINGER

Ensure front-line teams do their work correctly every time. Drag & drop digital procedures that unlock operational excellence.

In seconds anyone can build and deploy enterprise-grade mobile applications using an easy drag-and-drop no-code builder.

FAT FINGER uses machine learning to coach app users in real-time to make safer and improved decisions.

Try building your digital procedure on FAT FINGER for free @ www.fatfinger.io