When it comes to workplace safety, the Take 5 procedure is one of the most important things you need to know. The steps involved in Take 5 safety are designed to help workers identify and control hazards in the workplace, preventing injuries and accidents.

Take 5 safety is a simple procedure that can make a big difference in the safety of your workplace. Here’s everything you need to know about Take 5 safety.

Table of Contents:

I. What is Take 5 Safety?

II. Challenges in Using Traditional Checklist during Take 5 Safety

III. What are the Take 5 Steps?

IV.Take 5 Safety Digital Checklist

What is Take 5 Safety?

Take 5 Safety is a program that encourages people to take five minutes to think about safety before starting their work day.

The goal of Take 5 Safety is to reduce the number of accidents and injuries by promoting mindfulness and safe work habits. Take 5 Safety is based on the principle that most accidents are preventable if workers take the time to pause and think about their actions. By taking just five minutes to reflect on their work environment, workers can identify potential hazards and take steps to avoid them.

In addition to reducing the number of accidents, this also promotes healthy work habits and can help workers feel more alert and focused.

Take 5 Safety is an important part of keeping ourselves and our industries safe, and it is something that we should all take seriously.

Challenges in Using Traditional Checklist during Take 5 Safety

Paper-based inspection systems have been the traditional method for logging and tracking safety issues and near misses in many industries. Although paper-based reporting is vital to safety programs, it has several disadvantages.

1.It can be difficult to track safety incidents when they are scattered across multiple forms. This can potentially lead to a delay in reporting an incident, which could have serious consequences.

2.Paper records are often difficult to read and can be lost or damaged.

3.Paper reporting systems can be susceptible to errors, omissions, and data entry mistakes.

4.It can be difficult to track progress on incident audits when using a paper-based checklist as workers may not have access to real-time data.

5.Paper-based checklist can be difficult to scale and manage for large industries especially if data analysis is required.

In sum, paper-based inspection checklist can be difficult to use and maintain, and they often don’t provide the level of flexibility and adaptability that digital incident reporting systems do.

What are the Take 5 Steps?

When it comes to Take 5 safety, there are five key steps that workers need to take before starting their work day. The Take 5 Steps are easy to remember and can help prevent accidents. Since a Take 5 pre-task evaluation is completed before work begins, make sure you spend no more than 5 minutes assessing the key steps. The Take 5 steps are:

1. Stop and think

Before starting any task, it is important to take a moment to think about what you are about to do. What are the steps involved in completing the task? What could go wrong? Where you will be doing this activity?

For example, if you’re working with power tools, make sure to wear proper eye and ear protection. If you’re lifting heavy objects, use proper lifting techniques. And if you’re working in an area with potentially dangerous chemicals, take precautions to avoid exposure.

Remember, Take 5 safety is all about being proactive and thinking before you act. So if you take the time to stop and think, you’ll be much more likely to stay safe in any situation.

2. Look and Identify

This means that you take a moment to look around you and identify any potential hazards before proceeding. This step is crucial if you work in an unfamiliar environment or if the task is particularly dangerous. By taking a few seconds to assess the situation, you can ensure that you are aware of any potential risks and can take steps to avoid them. In some cases, it may also be necessary to consult with someone who is more familiar with the area or the task at hand.

3. Assess the risks

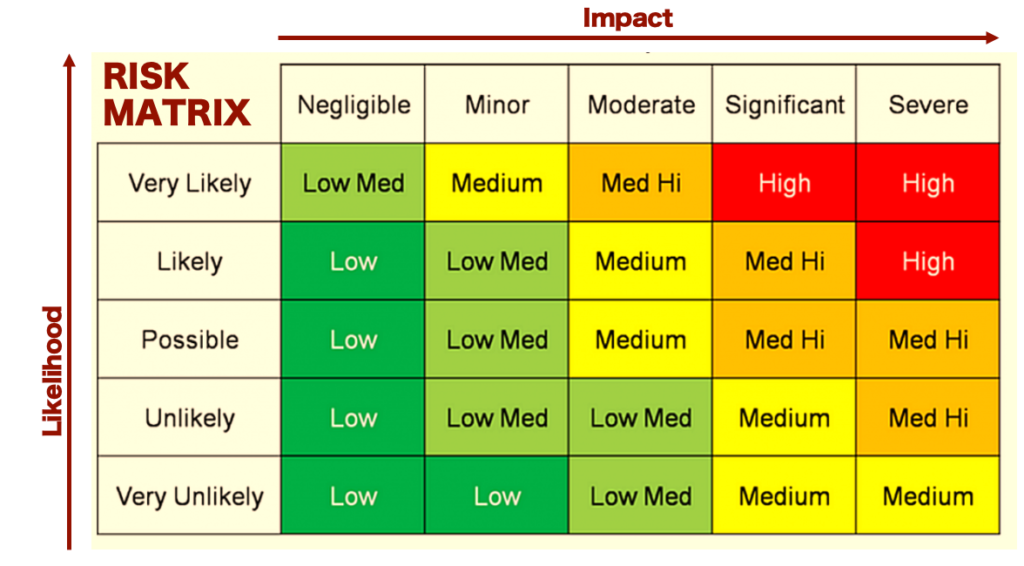

Once you have identified the potential hazards and imagined what could go wrong, it is time to evaluate the risks. What is the likelihood of an accident happening?

By evaluating the risks, you can decide whether or not the task is worth doing. If the risks are too high, it is important to find a safer way to do the task or to get help from someone who has more experience.

The risk matrix is a widely used decision-making tool to evaluate risk because it is practical and easy to use. Additionally, the matrix is flexible enough to be applied across different types of risks and situations. Some examples include using the tool to assess risks connected with a certain event or asset, as well as deciding which controls should be put in place for managing specific risks.

4. Control hazards

Once you have evaluated the risks, it is time to make a plan to do the job safely.

What are the steps you need to take to avoid the potential hazards? What safety equipment do you need to use? By making a plan, you can be sure that you are taking all of the necessary precautions to prevent an accident from happening.

Since Take 5 safety focuses on fast hazard management, acting on the best solution accessible to you right now is better than doing nothing at all to minimize a hazard or risks.

5. Monitor hazard

Only after you have taken the necessary precautions to avoid all potential hazards, may you begin work. However, once you have made a plan to control the hazards, it is important to follow it. Do not take shortcuts or take risks that you did not account for in your plan. If something goes wrong, make sure to stop and assess the situation before proceeding to work.

Take 5 Safety assessments can be difficult without a checklist. Carrying around numerous paperwork on a clipboard and a camera while manually checking and documenting hazards in the facility can be time-consuming and dangerous.

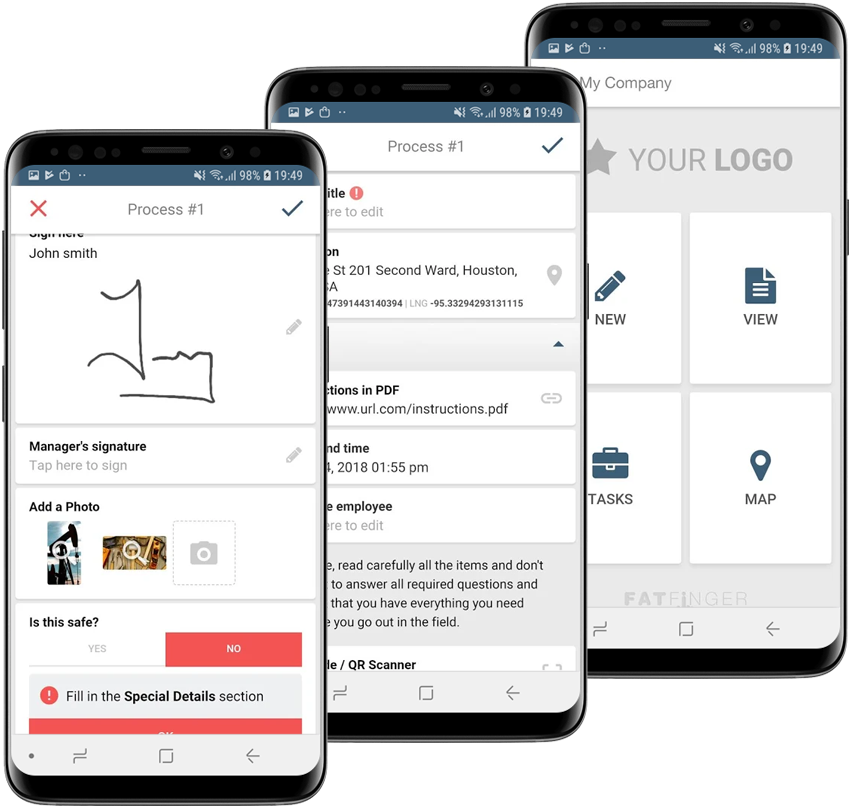

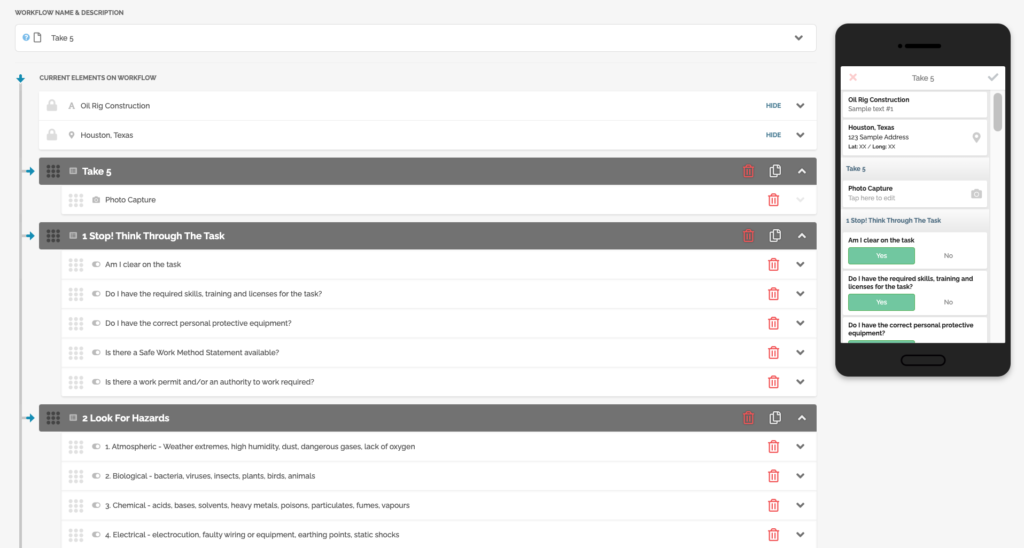

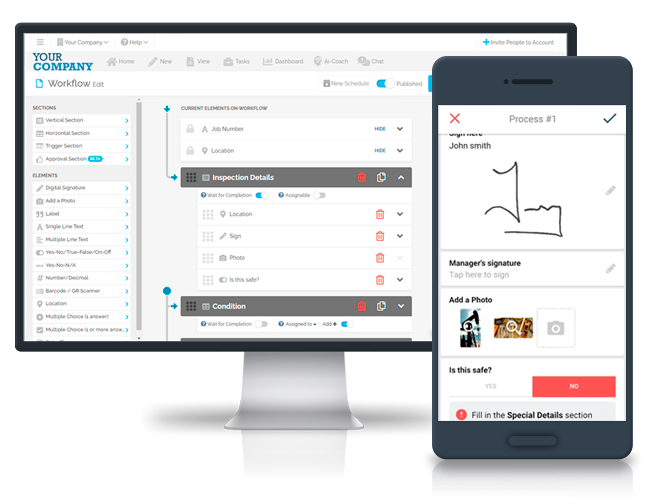

FAT FINGER makes safety assessments quick, easy, and accurate. Our digital templates guide workers through the Take 5 safety steps with customized response choices such as multiple choice, photos, text answers, and checkboxes.

This will help you identify key areas to improve so you can make better decisions about your workplace’s safety before getting started on your next tasks.

Take 5 Safety Digital Checklist

The Take 5 Safety digital checklist is a mobile solution that offers a number of advantages over traditional manual methods. For one, it is much faster and easier to use. Simply enter the job site information into the system and the Take 5 Safety checklist will generate a personalized list of safety precautions that need to be taken. This can save a lot of time and hassle, particularly on larger job sites.

In addition, the Take 5 safety checklist is more accurate than manual methods, as it takes into account a number of factors that could otherwise be overlooked. This can help to ensure that jobs are carried out safely and effectively, preventing accidents and injuries.

FAT FINGER can help in Take 5 safety checklist with an easy-to-use, accurate, and complete digital platform for safety assessments.

Safety is key in the workplace, and with FAT FINGER you can easily communicate hazard updates anytime and anywhere.

FAT FINGER makes it easy for you to automate workflows and schedule tasks so they’re done correctly every time – without any coding!

You’ll be able to clearly communicate hazard updates with images and facts, so everyone will be on the same page. Our mobile app makes it possible for you to identify key areas of improvement so you can focus your efforts where they’re needed most.

Stop wasting time and money on safety hazards that could have been prevented. Sign up at FAT FINGER today!

About FAT FINGER

Ensure front-line teams do their work correctly every time. Drag & drop digital procedures that unlock operational excellence.

In seconds anyone can build and deploy enterprise-grade mobile applications using an easy drag-and-drop no-code builder.

FAT FINGER uses machine learning to coach app users in real-time to make safer and improved decisions.

Try building your digital procedure on FAT FINGER for free @ www.fatfinger.io

Inspections for everyone – Anytime and anywhere.

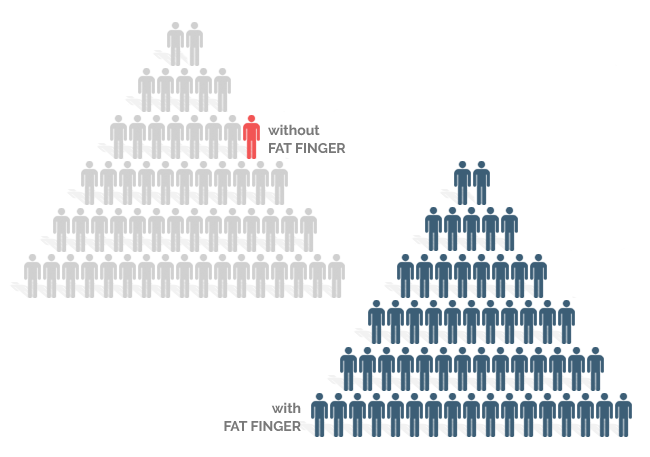

We empower EVERYONE to initiate and create positive change to improve the company’s safety records. The only way to keep up with the speed at which the world moves today is to empower everyone from the front-line worker to the executive.

Intuitive digital workflow – Paperless and powerful.

Every site has its own potential hazards. In FAT FINGER you will be able to import different incident reporting procedures and make them your own, or simply create one from scratch. And once you are done, you will be able to export your incident reporting workflow to all of your different sites.

Data powerhouse – Keeping everything in one place.

FAT FINGER is the right place where to do all your safety inspection checklists before performing risky tasks out in the field. And also allows any employee to share information in real-time with the entire team, such as photos of a potential near miss.