Quality assurance ensures that all aspects of a project are completed to meet the required standards.

This article will introduce a quality assurance checklist essential for any project.

Table of Contents:

1. Quality assurance vs. Quality Control

2. Importance of Quality Assurance

3. Best Practices for Quality Assurance

4. Quality Assurance Checklist with FAT FINGER

Quality Assurance vs. Quality Control

Quality assurance (QA) and quality control (QC) are two terms often used interchangeably, but they represent two different concepts. Quality assurance is a proactive process that is designed to prevent defects from occurring in the first place.

On the other hand, quality control is a reactive process intended to identify and correct defects after they have already occurred. While they have a different focus, Quality assurance and quality control share many similarities. Both involve setting standards, measuring performance, and taking corrective action when necessary. In addition, both require close attention to detail and strong communication skills.

While quality assurance and Quality control are essential for ensuring a product’s or service’s quality, they each represent different approaches to achieving this goal. By understanding the critical differences between these two concepts, businesses can choose the method that best meets their needs.

Importance of Quality Assurance

Quality assurance, therefore, sits at the heart of an engineering project, ensuring that the final product meets all the requirements and is fit for purpose.

1. Ensure that engineering projects meet all requirements and specifications. In today’s competitive marketplace, Quality assurance is essential for success. Forward-thinking companies understand that Quality assurance is not optional but a necessary part of any successful engineering project.

2. Identify and correct errors during the development process before the product is released to the public. As a result, QA can save time and money by preventing expensive mistakes from being made. By investing in Quality assurance, companies can reap the rewards of improved customer loyalty and increased sales

.3. Build trust between the engineering team and the client. Ensuring that projects meet all expectations, QA can help create a reputation for reliability and excellence. Quality assurance is not optional but an essential part of any successful engineering project. Quality assured products and services are vital in maintaining customer confidence and satisfaction.

4. Ensure that engineering projects are completed on time and within budget. Ensuring that projects meet all expectations, QA can help create a reputation for reliability and excellence.

Qualified and experienced engineers should be involved in quality assurance from the beginning of the project to ensure that the finished product meets all expectations. Quality assurance can help improve the overall satisfaction of the customer or client and the company’s reputation.

Best Practices for Quality Assurance

Quality assurance is a process that helps to ensure that products and services meet the highest possible standards. There are various ways to approach quality assurance, but one of the most popular methods is known as the Plan-Do-Check-Act (PDCA) cycle.

This model provides a structured approach for identifying best practices, implementing improvements, and monitoring results.

1.Plan. Quality Assurance teams develop Quality Plans that outline the best practices for ensuring quality.

The Quality Plan should be tailored to the project’s specific needs and should be reviewed and updated regularly.

2.Do. Quality Assurance teams implement the Quality Plans and monitor compliance. Quality Plans should be followed as closely as possible to ensure maximum effectiveness.

3.Check. Quality Assurance teams audit compliance and identify any areas of non-compliance. Corrective action should be taken to address any areas of non-compliance.

4. Act. Quality Assurance teams take corrective action to address any areas of non-compliance. Quality Plans should be updated as necessary to prevent future problems.

As a result, a Plan-Do-Act-Check method is an essential tool for any business that wants to ensure high levels of quality assurance. By following this process, organizations can continuously improve their products and services while ensuring that customer requirements are met.

Quality Assurance Checklist with FAT FINGER

Quality assurance can be applied to various product or service aspects, including design, development, production, delivery, and support. Quality assurance is often seen as a proactive approach, aimed at preventing defects from occurring in the first place. Without a good quality assurance program, you risk your products and customers’ satisfaction.

Quality audits are necessary for any business looking to ensure that its products and services meet the required standards. However, conducting these audits can be very time-consuming and require a lot of resources from the organization.

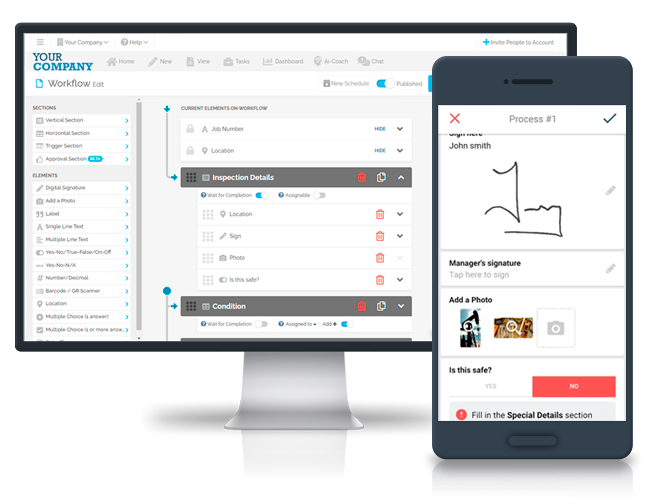

FAT FINGER is an easy-to-use quality assurance tool that makes it simple to track your progress during an audit, identify problem areas, and find solutions quickly.

With FAT FINGER, you’ll spend less time worrying about the audit process and more time improving your business. With FAT FINGER quality assurance checklist, users are empowered to:

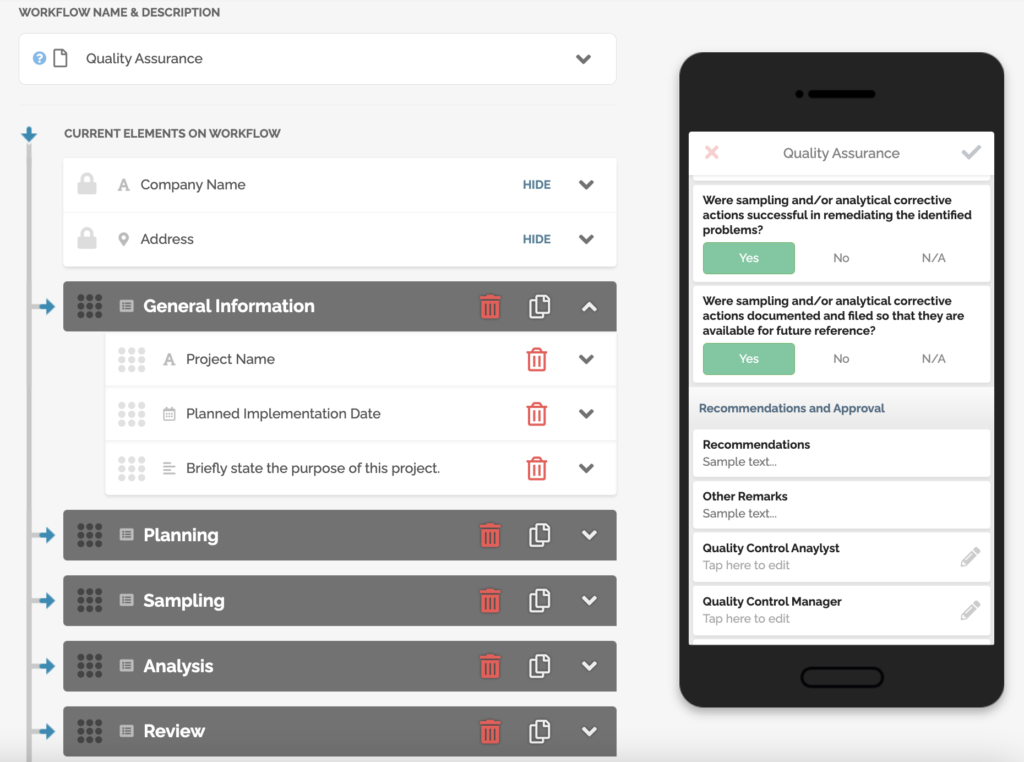

-Create a customized workflow that suits your quality assurance needs.Remarks, corrective actions, and photos collected during inspections can be added to the workflow.

-With quality assurance templates available on mobile devices, authorized users can assign and conduct audits to gather relevant data, streamlining the process for teams of all sizes – anytime and anywhere.

-Generate reports on-site and send them to relevant stakeholders via email, PDF, or web link. This way, everyone can stay up-to-date on the latest information.

-Assign tasks and schedule your next quality assurance plan directly from the app. This ensures everyone is on the same page and no one misses a beat.

-Data collection with the app can give you powerful insight into where your quality stands now and what corrective actions need to be taken.

With FAT FINGER, you’ll have everything you need to pinpoint where to focus next to improve your quality assurance program. Improve your business today with FAT FINGER!

About FAT FINGER:

Ensure front-line teams do their work correctly every time. Drag & drop digital procedures that unlock operational excellence.In seconds anyone can build and deploy enterprise-grade mobile applications using an easy drag-and-drop no-code builder.

FAT FINGER uses machine learning to coach app users in real-time to make safer and improved decisions. Try building your digital procedure on FAT FINGER for free @www.fatfinger.io

Quality assurance reporting made easy for everyone

We empower EVERYONE to initiate and create positive change to improve the company’s quality records. The only way to keep up with the speed at which the world moves today is to empower everyone from the front-line worker to the executive.

Build and customize your safety procedures in seconds

Every site has its own potential hazards. In FAT FINGER you will be able to import different quality processes and make them your own, or simply create one from scratch. And once you are done, you will be able to export your quality assessment workflow to all of your different sites.

Quality insights in real-time

Every single piece of information captured by your FAT FINGER users will feed your company analytics in real-time. Adopting FAT FINGER will give you show you the risky points of your operations and how to make them risk-free.