This post takes an in-depth look into the role quality control plays in safety management in manufacturing.

It also introduces FAT FINGER as a solution for workplace safety implementation.

The relationship between quality control and workplace safety management may seem tenuous.

This is because Quality Control is primarily understood in the context of end-product quality.

But quality control has far-reaching consequences than that, and plays a critical role in safeguarding workplace safety in manufacturing.

For instance, the 2006 explosion at Falk Corporation is a classic case of how a lack of quality control in a manufacturing plant can result in an unsafe workplace.

The explosion, which killed three people and injured 47, resulted from a leaking gas pipe underneath the factory.

Had quality control procedures been created and thoroughly followed, safety recommendations may have been implemented, and the crisis averted.

Similar incidents are reported globally each year. And while the cause of each accident may vary, the lack of quality control processes is the underlying problem.

Quality control minimizes legal and financial risk.

Every time there is an accident at work, investigations are carried out, and more often than not, the business incurs heavy financial losses as a result of:

- Compensation payouts

- Penalties for non-compliance with safety standards

- Cost of reconstruction

- Training new workers

- PR campaigns to repair a damaged brand image

But all these risks to your company’s bottom line can be prevented with a risk and safety management system like FAT FINGER.

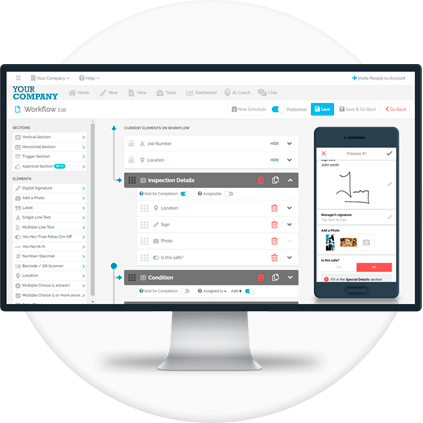

With our no-code builder, you can create a quality management system for manufacturing to help your team:

- Define quality control criteria

- Create and implement a practical quality control checklist

- Digitize your existing quality control forms

- Automate quality control

1 – Identifying and mitigating safety hazards

A quality control system outlines inspection procedures to identify potential risks and hazards in your manufacturing plant. Potential safety hazards may include:

- Clutter. Workers can trip over wires, hoses, maintenance tools, equipment such as forklifts, or packing material outside their designated storage space.

- Small floorspace. A crowded factory will likely experience overheating, toxic fumes accumulation, and low oxygen levels.

- Blocked emergency exits. A minor accident could worsen if exit routes are blocked or too small.

- Overworking. Exhaustion from long shifts can dull your workers’ judgment, making them less aware of dangers.

FAT FINGER enables you to create workflows for Job hazard analysis, letting you know beforehand where potential safety hazards lie.

With this knowledge, you can create and implement procedures to prevent injuries.

Such procedures may be as simple as requiring workers to take periodic rest when using heavy machinery or as technical as implementing machine guarding practices.

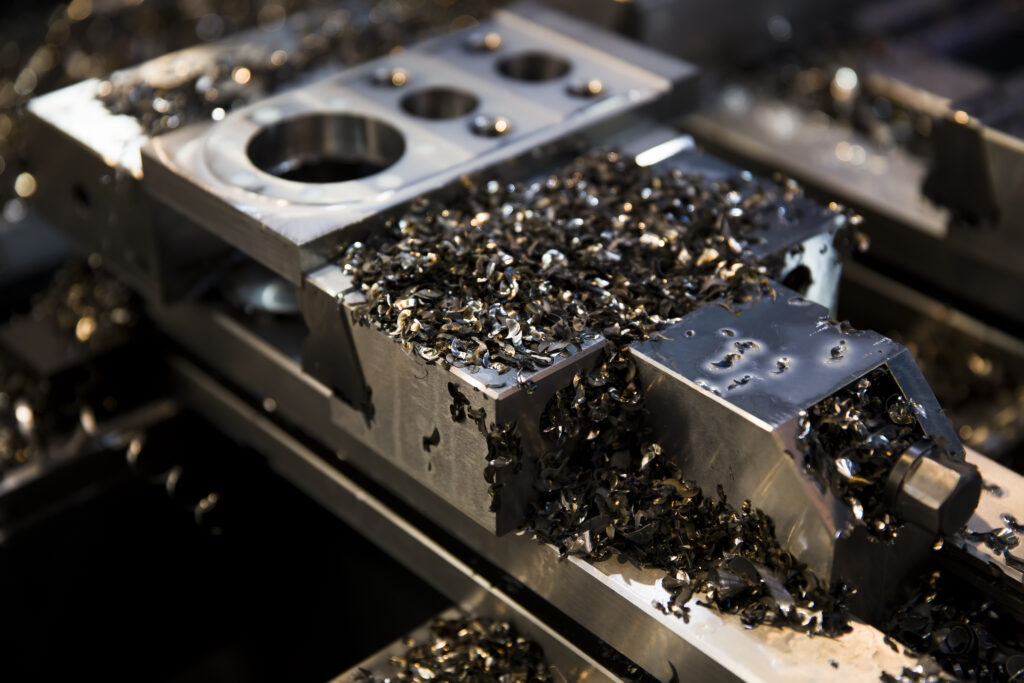

2 – Enhanced Equipment Reliability

Quality control procedures ensure you keep machinery in reliable working condition.

Faulty equipment can be prone to explosions, collapse, or loose bits snapping off, resulting in injuries such as chopped limbs, lacerations, or death.

Case in point: The Qinghe Special Steel Corporation disaster occurred when a ladle carrying molten steel snapped off its rail hoisting.

Investigations into the incident revealed that:

- The hoist used needed to be of the right quality for smelting work. The standard hoist could not withstand molten steel’s weight (30 tons) and heat (2730 F).

3 – Cultivating a culture of safety

Cultivating a culture of safety begins with bridging any disconnect in how employees and managers view safety and what contributes to an unsafe workplace.

Take workplace fatigue, for instance. One survey found that while 98% of employers agreed that fatigue can increase the risk of accidents in manufacturing, only 77% of their employees agreed.

Making safety a core company value will help you encourage company-wide buy-in.

But this is easier said than done when using traditional, inefficient methods such as printouts of detailed training manuals.

A better approach is to simplify the adoption of safety procedures.

When you simplify things, you can build consistency in how everyone in your organization perceives safety and promote responsible behavior in the workplace.

Instead of rigorous and complicated training, you can build simple take-5 safety procedures in your work environment, making adopting safety procedures second nature.

4 – Compliance with Regulatory Standards

Manufacturing is subject to several regulatory standards to safeguard workers’ welfare. They include:

- International Labor Standards. The International Labor Organization (ILO) has over 40 standards and 40 codes of practice governing workplace safety.

- The International Organization for Standardization (ISO). The ISO has hundreds of safety standards for the manufacturing industry.

Other regulatory standards from governing bodies like the IAEA and EPA may also apply to your organization, depending on your industry.

All these regulatory bodies require your company to demonstrate compliance by showing that they have implemented the required regulations and practices.

Enhancing Workplace Safety With FAT FINGER

Quality Control and workplace safety in manufacturing go hand in hand.

When workers are safe, your business minimizes legal risks associated with paying accident compensation and workman’s benefits.

With a no-code application builder like FAT FINGER, you can build an intuitive quality management system to help you:

- Access quality control insights to make smarter decisions

Reliable data helps you to stay mindful of safety hazards and devise ways to prevent them.

You can view real-time workplace safety data on the FAT FINGER dashboard and make speedy decisions to prevent injuries common in the manufacturing industry.

- Improve adoption of quality control standards

Adopting quality control standards in your business processes can help you catch equipment defects before they happen.

You can customize your quality control sheets in FAT FINGER to allow your field teams to attach photos of any defects they find.

Adding a contact number allows your team to contact you when immediate action is needed.

- Leverage AI and machine learning to improve processes.

Trying to identify gaps in employee training manually can take time and effort.

The AI Coach on FAT FINGER provides real time coaching, meaning you never have to worry about knowledge gaps.

You can create your workflow on FAT FINGER from scratch. You can also customize this Quality Control for Workplace Safety Management template.

Below are some of the ways to customize this template:

- You can create offline workflows

- Invite teams users

- Schedule tasks

- Integrate with tools you already use, such as Microsoft BI, Azure, Snowflake, ESRI, and Azure Synapse.