When it comes to excavation work, numerous hazards must be assessed and controlled to ensure the safety of workers. The most effective way to conduct such an assessment is with a Job Hazard Analysis (JHA) for excavation work.

This article delves into the steps for conducting a Job Hazard Analysis for excavation work.

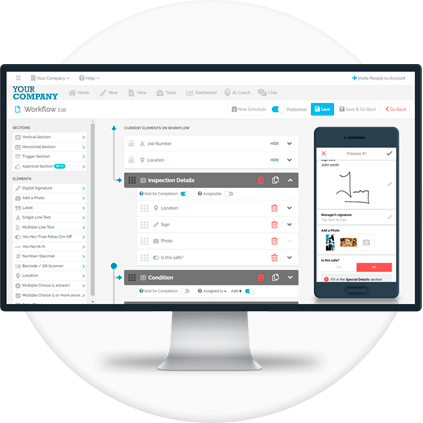

It also recommends FAT FINGER as the best application to build and deploy your Job Hazard Analysis (JHA) Workflow and enhance safety levels during excavations.

FAT FINGER is a no-code, drag-and-drop builder. Therefore, anyone can build enterprise-grade applications in minutes.

10 Steps to Conduct a JHA During Excavations

A Job Hazard Analysis (JHA) -also known as a Job Safety Analysis (JSA), is a systematic process for identifying and mitigating potential hazards associated with specific job tasks or activities.

Below are ten steps to conduct a Job Hazard Analysis for excavation work;

Step 1 -Select the Job/Task

Clearly define the specific excavation task to be analyzed. This might include tasks such as digging trenches, excavating for foundations, or creating utility lines.

Step 2 -Identify a Team

Assemble a team of knowledgeable and experienced individuals in excavation work. This team may include supervisors, equipment operators, safety officers, and workers who will perform the task.

Step 3 -Break down the Job

Divide the excavation task into distinct steps or phases. For example, for a trench excavation, steps might include site preparation, trench digging, installation of protective systems, and back filling.

Step 4 -Identify Hazards

For each step or phase of the excavation process, identify potential hazards.

Here are more detailed considerations for common excavation hazards:

a. Cave-ins: The risk of the excavation collapsing is a significant hazard.

- Analyze soil types and stability to assess the risk of trench collapse.

- Consider the depth of excavation and the potential for sidewall sloughing.

b. Falling Objects: Evaluate the likelihood of objects falling into the excavation, such as equipment, materials, or soil from the sidewalls.

c. Utility Strikes: Identify the presence of underground utilities. Assess the risk of striking utilities while excavating.

d. Engulfment: Workers can be engulfed while inside the excavation. Examine the possibility of workers being trapped or engulfed by materials or soil.

e. Trench Collapse: Assess the stability of trench walls and the necessity for protective systems like shoring, sloping, or trench boxes.

f. Hazardous Atmosphere: Determine if the excavation site might contain hazardous gases or chemicals and evaluate the need for air monitoring and confined space entry procedures.

g. Heavy Equipment: Consider the risks of using heavy machinery, including rollovers, collisions, and safe operating practices.

h. Weather Conditions: Account for weather conditions affecting excavation safety, such as rain, which may destabilize soil.

Step 5 -Risk Assessment

After identifying excavation hazards , assess the risk associated with each hazard by considering the likelihood and severity of potential incidents.

Step 6 -Implement Controls

Develop and implement control measures to mitigate or eliminate hazards. Some examples of control measures include:

a. Protective Systems: Use shoring, sloping, or trench boxes to prevent cave-ins.

b. Barricades and Warning Signs:

Install barriers and signage to prevent unauthorized entry into the excavation area.

c. Utility Locates: Contact utility companies to locate underground utilities before excavation.

d. Training: Ensure all workers are trained on safe excavation practices and hazard-specific protocols.

Step 7 -Document the JHA

Create a written document outlining the excavation task, identified hazards, risk assessment, and control measures. Ensure all workers involved in the excavation job have access to this document.

Step 8 -Review and Update

Regularly review and update the JHA as conditions change, new hazards arise, or new control measures become available.

Step 9 –Training

Ensure that all workers involved in excavation work are adequately trained on the JHA and the specific safety procedures for the job. Regularly reinforce safety practices through toolbox talks or safety meetings.

Step 10 -Supervision and Monitoring

Assign a competent person to supervise the excavation work and monitor safety compliance throughout the job. Encourage workers to report hazards or unsafe conditions.

By following these steps and incorporating them into your excavation work practices, you can help ensure the safety of workers and reduce the risk of accidents and injuries associated with excavation tasks. Always remember excavation work can be particularly hazardous, so a thorough analysis and robust safety measures are essential.

Easy Job Hazard Analysis for Excavation Work With FAT FINGER

Managing safety in excavation work is easy with FAT FINGER -a user-friendly, no-code application builder.

Whether you prefer to build your safety workflow from the ground up or customize our pre-existing templates, FAT FINGER offers extensive flexibility to:

- Design offline workflows tailored to your specific needs

- Invite team members to collaborate seamlessly

- Schedule tasks efficiently

- Integrate with existing tools such as Microsoft BI, Azure, Snowflake, ESRI, and Azure Synapse

- Harness the potential of AI and machine learning to streamline your processes

Once you have your FAT FINGER workflow up and running, you will:

- Gain access to valuable quality control insights for informed decision-making.

- Remain vigilant about safety hazards and devise proactive measures to prevent them.