Shutdown and turnaround are essential aspects of maintaining and optimizing industrial facilities, whether they are in the petrochemical, manufacturing, or energy sectors. These planned outages provide organizations with the opportunity to inspect, repair, and upgrade equipment, ensuring the continued safe and efficient operation of their plants.

However, the process can be complex, costly, and time-consuming if not well-managed. In this article, we’ll demystify shutdowns and turnarounds to help your organization effectively plan and execute these critical events. We’ll also tell you why using FAT FINGER’s shutdown checklist is the best way to manage this maintenance process.

What Are Shutdowns and Turnarounds?

To understand shutdowns and turnarounds, let’s start with the fundamentals.

Shutdowns

A shutdown, also known as a “planned outage,” is a temporary suspension of plant operations in specific units or even entire industrial plants. These outages are typically done for routine maintenance, inspections, and minor repairs. Shutdowns are often shorter, usually from a few hours to a few days.

Shutdowns are what equipment and systems require to remain in optimal working condition.

Turnarounds

Turnarounds, sometimes called outages, are more encompassing than regular shutdowns. They occur periodically, often every few years, and go beyond maintenance. Turnarounds involve substantial overhauls and modifications intended to elevate the overall performance and reliability of the facility.

Step by Step Shutdown and Turnaround Process

Step 1: Pre-Planning

- Define Objectives

Setting your goals and objectives is the first step in executing a successful shutdown or turnaround. What precisely do you want to accomplish during this planned break? Are you focusing on maintenance, replacing equipment, or optimizing performance? Clear objectives pave the way for a seamless process.

- Assemble a Team

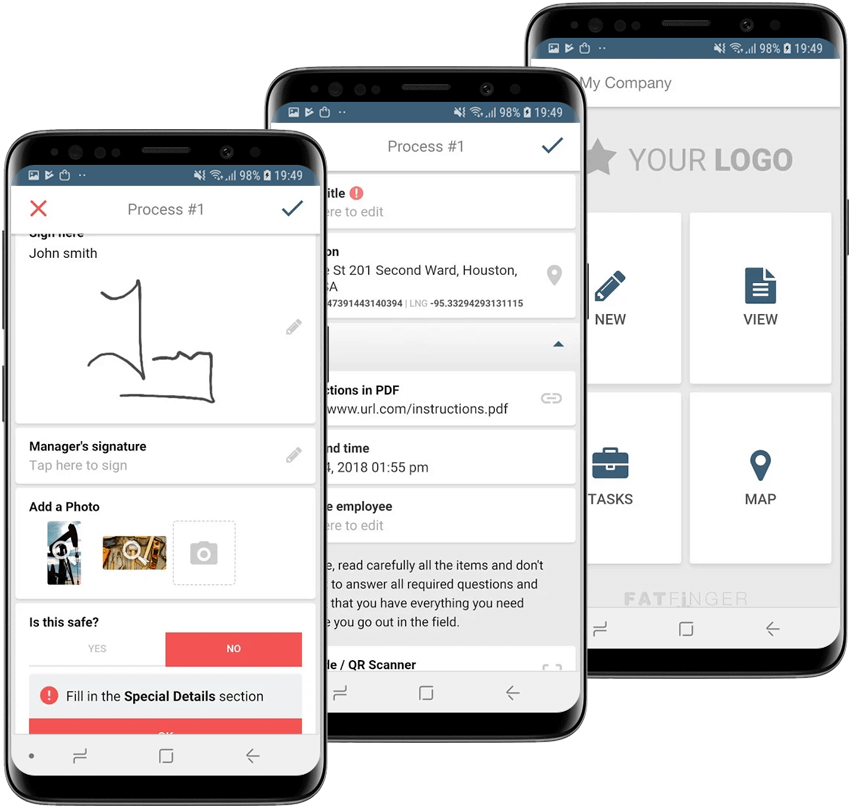

Constitute a team of individuals well-versed in the intricacies of shutdowns and turnarounds. Your team should ideally include planners, engineers, safety experts, and skilled technicians. Effective teamwork is key to a trouble-free operation. Keep everyone on the same page with FAT FINGER workflows. Every team member will know their specific objectives, and you can monitor all activities in real-time.

Step 2: Detailed Planning

Scope of Work

Create a meticulous scope of work. This document should outline every task that needs to be performed, from inspections and repairs to equipment replacements and potential upgrades. The scope of work acts as your roadmap during the event.

Budgeting

Establish a realistic budget, considering labor, materials, and any unforeseen costs that might surface. A carefully crafted budget safeguards the financial integrity of the project.

Step 3: Scheduling

- Timeline

Develop a comprehensive timeline that dictates when the shutdown or turnaround commences and concludes. This timeline is paramount in coordinating all the work, ensuring minimal downtime, and keeping the project on track.

- Critical Path Analysis

Identify the critical path of activities. These are the tasks that must be completed before others can commence. Recognizing the critical path ensures a logical sequence of work that avoids bottlenecks and delays.

Step 4: Safety and Compliance

Risk Assessment

Conduct a thorough risk assessment to identify potential hazards and perils. Implement stringent safety measures to safeguard your team and the environment from harm.

Regulatory Compliance

Compliance with industry regulations and standards is non-negotiable. Non-compliance can lead to costly penalties and legal complications.

Step 5: Execution

- Mobilization

As the scheduled date for the shutdown or turnaround approaches, mobilize the necessary resources, equipment, and personnel to the site. Proper preparation is the key to a smooth launch.

- Work in Phases

Execute the plan in well-defined phases, commencing with the most critical tasks. Regular progress monitoring allows for adjustments, ensuring the project stays on course.

Step 6: Quality Control

- Inspections

Regular and rigorous inspections are imperative to ensure all work meets the required standards. Any deviations from the plan should be addressed promptly.

- Testing

Before restarting operations, thorough testing is a must. This verifies that all systems function correctly, minimizing the risk of unexpected issues post-execution.

Step 7: Completion

- Documentation

Maintain detailed records of all work performed. Document changes made and any unforeseen issues that arose. This comprehensive record is invaluable for future reference.

- Post-Project Review

Gather your team for a post-project review. This is the moment to reflect on the entire process, discussing successes and areas for improvement. A candid post-mortem is the path to continuous enhancement.

Shutdown and Turnaround FAQs

1. Why are shutdowns and turnarounds necessary?

Shutdowns and turnarounds are necessary to ensure industrial facilities’ ongoing efficiency and safety. They allow for maintenance, repairs, and performance enhancements.

2. How often should a turnaround be conducted?

The frequency of turnarounds depends on the facility and its specific needs. However, they are typically conducted every few years to address accumulated wear and tear.

3. What are the key challenges during shutdowns and turnarounds?

Challenges include efficient resource and time management, safety measures, and adherence to regulatory requirements.

4. Can shutdowns and turnarounds be completed by anyone?

A skilled and experienced team is optional for the success of these operations. The collaboration and expertise of team members are essential for a smooth process.

5. What is the role of risk assessment in shutdowns and turnarounds?

Risk assessment is pivotal in identifying potential hazards and threats during the process. It helps implement safety measures to protect personnel and the environment.

Manage Shutdowns and Turnarounds with FAT FINGER

Shutdowns and Turnarounds are crucial but they can be difficult to run without the right tools.

Running these processes without digital workflows, will likely result in the following:

- Inefficient shutdowns and turnarounds, leading to long delays in production hence increased costs

- Increased asset risk as you have no workflows to guide you

- No data means you’re operating blind, leading to running equipment to the point of failure

FAT FINGER is the answer to running seamless, smooth, effortless transitions.

Our intuitive digital procedure gives you control over scheduling, scope management and budgeting.

Take control today with FAT FINGER’s comprehensive shutdown checklist or customize your own with the drag and drop editor.