A risk assessment is an essential tool for mitigating potential workplace hazards. By identifying and analyzing potential risks, you can implement measures to eliminate or control them, keeping your employees safe and productive.

A risk assessment checklist is a thorough look at your workplace that can help you identify those things, situations, processes, etc., that may cause harm.

Table of Contents:

1. What is Risk Assessment?

2. Disadvantages of Paper-based Risk Assessments

3. Benefits of Risk Assessments

4. How to Conduct Risk Assessment?

5. FAT FINGER as your Reliable Risk Assessment Partner

What is Risk Assessment?

Risk assessment is identifying, assessing, and managing potential risks to an organization. It includes risk analysis, which is the process of identifying and quantifying risks, and risk management, which is the process of mitigating or reducing risks. Risk assessment is identifying, assessing, and managing potential risks to an organization.

It includes risk analysis, which is the process of identifying and quantifying risks, and risk management, which is the process of mitigating or reducing risks.

Risk assessment is a critical part of any engineering or industrial operation, as it helps to ensure safety and compliance with regulations. In the manufacturing sector, for example, risk assessment is used to identify and assess potential hazards associated with industrial processes. This information can then be used to develop safer production methods and improve worker safety. Risk assessment is also an essential tool in emergency planning, as it can help to identify potential threats and develop plans to mitigate them.

Organizations can protect themselves from potentially damaging events by understanding and managing risks.

Disadvantages of Paper-based Risk Assessments

Risk assessment is critical in many industries, from engineering and manufacturing to other industrial sectors. Traditionally, risk assessments have been paper-based, using checklists to identify and assess potential risks. However, this approach has several limitations.

1.Paper-based checklists can be time-consuming and tedious to fill out. Engineering projects are often fast-paced and dynamic, so having to stop and complete a paper-based risk assessment can slow down the work.

2. It can be challenging to identify all potential risks when using a paper-based checklist. This can lead to missed risks, potentially leading to accidents or other problems.

3. Paper-based checklists can be lost or misplaced, jeopardizing the project’s safety.

4. Paper-based checklists may not always be up-to-date with the latest risk information. As a result, they may not be as effective at identifying new or emerging risks.

5. Tracking historical risk data using paper-based checklists is a challenge, especially in large industries, because of double entry, and manual tasks. Risk data are essential for understanding trends and developing strategies to prevent future accidents.

These challenges have led to the developing of new risk assessment tools, such as digital risk management workflow. This platform offers more accurate and reliable risk analysis than paper-based assessments. As a result, it is becoming increasingly popular in the industry because of its promising solutions.

Benefits of Risk Assessments

Risk assessment is an integral part of engineering and the industrial sector. It helps organizations make informed decisions about how to manage risks and can also be used to identify opportunities for improvement. Risk assessment has many benefits, including:

– Improved decision-making: Risk assessment can help organizations make better decisions about risks taking and how to minimize the impact of potential hazards.

– Improved communication: Risk assessment can help to enhance communication between different departments and stakeholders within an organization.

– Identification of potential problems: Risk assessment can help organizations identify potential issues before they occur, which can help avoid costly accidents or disasters.

– Improved safety: Risk assessment can help organizations to improve safety by identifying and assessing risks. This can help to reduce the number of accidents and injuries.

– Reduced liability: Risk assessment can help organizations to facilitate their liability by identifying and managing risks.

– Improved reputation: Risk assessment can help organizations to improve their reputation by demonstrating their commitment to safety and risk management.

Ultimately, risk assessment is a powerful tool that can profoundly impact the safety of workers, industries, and society as a whole.

How to Conduct Risk Assessment?

Risk assessment is a vital step in the risk management process, and it can be used to identify potential hazards, assess the risks they pose, and develop mitigation strategies. The steps involved in conducting a risk assessment are:

1. Identify potential hazards. This can be done by looking at the work environment, equipment, and materials used. This can also be done by brainstorming with the team or reviewing previous risk assessments for similar projects.

2. Evaluate the risks posed by each hazard. First, it is crucial to consider the likelihood of the hazard occurring. What is the probability that the hazard will happen, and what is the potential severity of the consequences? Second, it is essential to consider how vulnerable the system is to the hazard. What are the weaknesses in the system that the hazard could exploit?

3. Identify and implement mitigation strategies to reduce the risks posed by each hazard.This involves designing systems and processes that are resistant to the effects of a given hazard. In some cases, it may also be possible to implement administrative controls, such as safety training programs, to reduce the likelihood of accidents. The industrial sector also offers a variety of resources, such as safety data sheets and chemical hazard information, that can be used to develop mitigation strategies.

4. Record your risk assessment.

When conducting a risk assessment, it is essential to record all data carefully to have a unified source of information and make an informed decision about mitigation strategies.

This helps to ensure that all risks have been considered and strategies are in place.

5. Monitor and review the effectiveness of mitigation strategies.

This allows for determining whether the strategies are working as intended and whether they need to be modified or replaced. By monitoring and reviewing mitigation strategies, you can ensure that they are doing what they’re supposed to do and keeping people safe. This can be done through regular inspections and audits, as well as by tracking changes in safety data over time.

Risk assessments are critical for ensuring workers’ safety in the industrial sector. By following these steps, companies can ensure that they take all necessary measures to protect their employees and prevent accidents.

A digital checklist can help to streamline the risk assessment process by providing a structured approach to identifying and evaluating risks. Checklists help to ensure that all potential risks are considered and that no steps are missed during the risk assessment process. However, risk assessment can be time-consuming, mainly when done manually.

Fortunately, new digital workflow software like FAT FINGER has made it possible to create digital checklists that can accelerate the risk assessment process.

Using the digital checklist during risk assessment in the industrial and engineering sector offers many advantages and can help ensure that all potential risks are considered. FAT FINGER features:

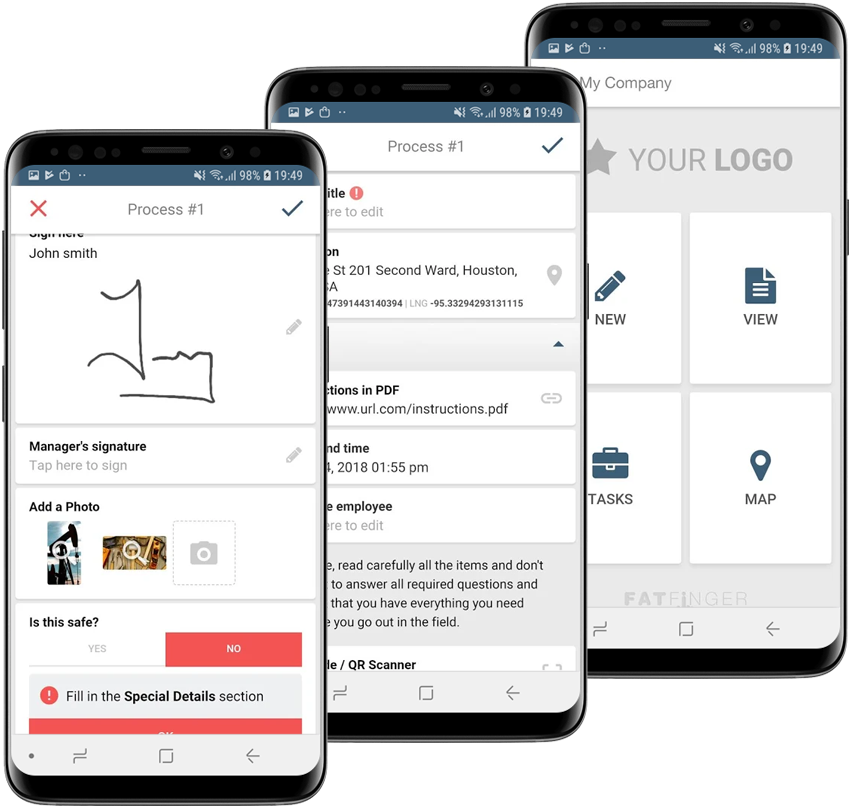

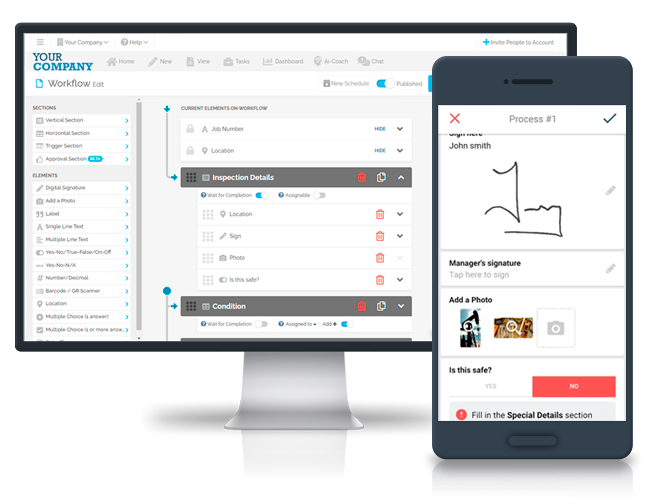

Intuitive digital workflow – Paperless and Powerful.

FAT FINGER’s digital risk assessment checklist is designed to streamline the risk data collection process and make it easy to generate professional reports. With our intuitive workflow, you can quickly customize your checklist with images and video to create workflows with No-Code directly where work is done. Automatically generate reports with one click and share them with stakeholders.

Advanced Analytics- What gets measured, gets managed.

FAT FINGER’s digital risk assessment checklist is easy to use and provides you with valuable insights to help improve your workplace safety. With our detailed dashboards, you can quickly identify areas of improvement and track your progress over time.

Data powerhouse – Keeping everything in one place.

All your up-to-date work risk assessment findings, mitigation strategies, and training content are available across any device as employees perform the work. Data are stored in the cloud and available in real-time to everyone who needs it.

Inspections for everyone – Anytime and anywhere.

No matter your location, you can use or view your risk assessment checklist on any device with a web browser or FAT FINGER app. Whether at the job site or in the office, you can easily collect data and generate reports.

FAT FINGER was designed to create the most reliable and user-friendly digital checklist software. With FAT FINGER, you can have peace of mind knowing that safety is always the number one priority.

Sign up for a free trial of FAT FINGER today.

About FAT FINGER:

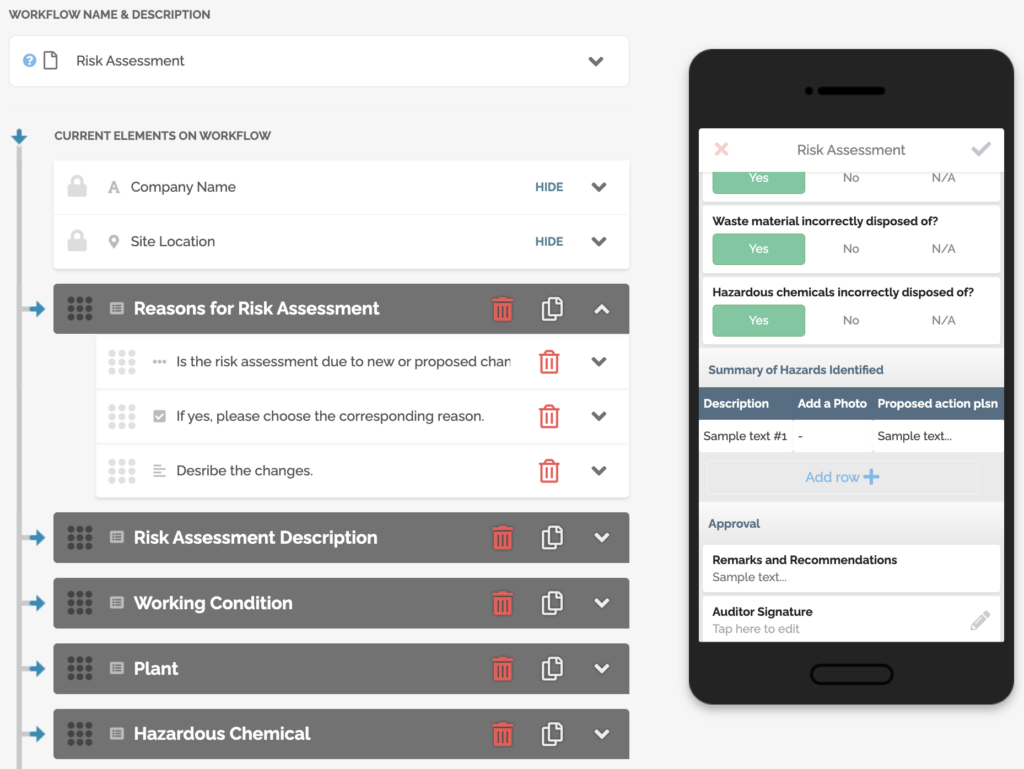

Ensure front-line teams do their work correctly every time. Drag & drop digital procedures that unlock operational excellence.

In seconds anyone can build and deploy enterprise-grade mobile applications using an easy drag-and-drop no-code builder.

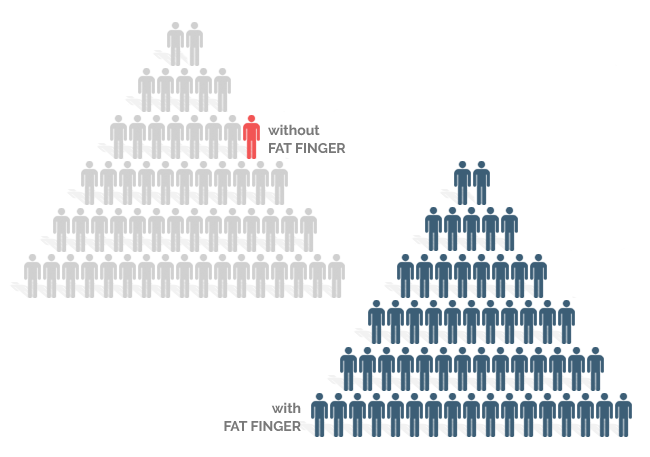

FAT FINGER uses machine learning to coach app users in real-time to make safer and improved decisions.

Try building your digital procedure on FAT FINGER for free @ www.fatfinger.io

Risk assessment made easy for everyone

We empower EVERYONE to initiate and create positive change to improve the company’s safety records. The only way to keep up with the speed at which the world moves today is to empower everyone from the front-line worker to the executive.

Build and customize your risk reporting procedures in seconds

Every site has its own potential hazards. In FAT FINGER you will be able to import different risk reporting procedures and make them your own, or simply create one from scratch. And once you are done, you will be able to export your incident reporting workflow to all of your different sites.

FAT FINGER is a key risk reporting tool

FAT FINGER is the right place where to do all your risk reporting checklists before performing risky tasks out in the field. And also allows any employee to share information in real-time with the entire team, such as photos of a potential near miss.