As the energy sector continues to evolve, the need for improved safety and efficiency has never been more critical. One solution that is making a significant impact is the concept of the ‘connected worker’. This approach leverages digital technology to enhance communication, streamline processes, and improve safety. A key player in this field is FAT FINGER, a digital workflow procedure builder that empowers front-line teams to do their work correctly every time.

Understanding the Connected Worker Concept

The Connected Worker concept is grounded on the premise that through the use of technological tools such as wearables, augmented reality (AR), virtual reality (VR), mobile devices, and internet of things (IoT) devices, workers can stay connected with each other, with their supervisors, and with their work environment in real-time.

This concept has three main aspects:

1. Communication: Connected workers can easily communicate with their coworkers, supervisors, and other relevant people. This can be via messaging, video conferencing, data sharing, etc. This real-time communication facilitates quick decision-making, immediate problem-solving, and efficient teamwork.

2. Data Access and Sharing: Through IoT devices and cloud technology, connected workers can access and share real-time data about the work environment, machinery, work progress, etc. This helps in maintaining transparency, avoiding errors, and improving the overall work quality. Moreover, it facilitates predictive maintenance, as any issue with the machinery can be detected early.

3. Safety: With wearables and sensors, connected workers’ health and safety can be monitored. For instance, workers in hazardous environments can be constantly monitored for signs of fatigue, excessive exposure, etc. Also, in case of any emergency, immediate alerts can be sent out, ensuring quick response.

In sum, the Connected Worker concept is about leveraging technology to create a work environment that is more efficient, collaborative, transparent, and safe. It’s a major step towards digitizing the industrial workforce and is being seen as a significant contributor to the Industry 4.0 revolution.

The Role of FAT FINGER in Connected Worker Dynamics

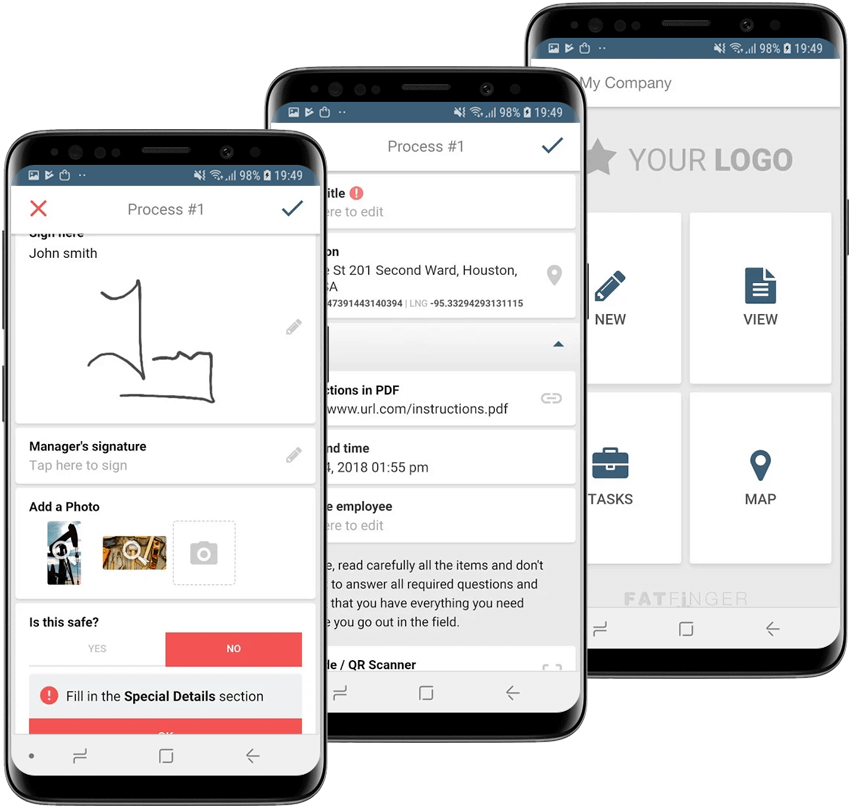

FAT FINGER is a leading solution in the connected worker space, offering a range of features designed to unlock operational excellence. These include a drag & drop workflow builder, mobile & desktop workflows, dashboards, integrations, augmented reality, IoT device connectivity, and artificial intelligence coaching.

With FAT FINGER, companies can create digital workflows and checklists across a range of safety, maintenance, and operations areas. These include safety procedures like near miss reporting and risk assessment, operations tasks like quality control and shift handovers, and maintenance activities like work order checklists and predictive maintenance.

Case Studies: Safety and Efficiency in the Energy Sector

Several case studies highlight the impact of Connected worker dynamics and FAT FINGER’s solutions in the energy sector.

Case Study 1: Improving Safety with Near Miss Reporting

One energy company implemented FAT FINGER’s near miss reporting solution to improve safety. The digital workflow allowed workers to quickly and easily report near misses, leading to faster response times and a reduction in accidents.

Case Study 2: Enhancing Efficiency with Quality Control

Another company used FAT FINGER’s quality control solution to streamline their operations. The digital workflow provided real-time access to quality control data, enabling the company to identify and address issues more quickly and efficiently.

Case Study 3: Boosting Maintenance with Predictive Maintenance

Energy companies also leverage FAT FINGER’s predictive maintenance solution to enhance their maintenance processes. The digital workflow allowed the company to predict and prevent equipment failures, leading to increased uptime and reduced maintenance costs.

Conclusion: The Power of the Connected Worker

The connected worker concept, powered by solutions like FAT FINGER, is transforming the energy sector. By leveraging digital technology, companies can improve safety, streamline operations, and enhance maintenance processes. The result is a more efficient, effective, and safe energy sector.

Ready to experience the benefits of the connected worker for yourself? Sign up for FAT FINGER or request a demo today.