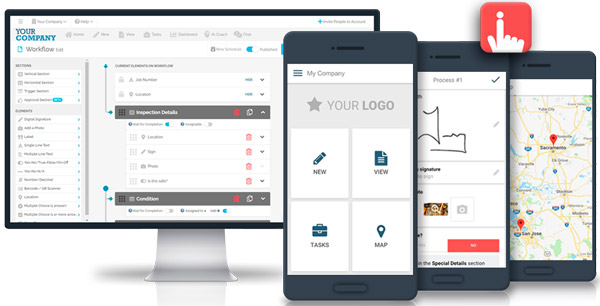

As industries evolve, so does the need for advanced safety measures. This is particularly true for high-risk industries such as construction, mining, and manufacturing. In this context, the Internet of Things (IoT) has emerged as a game-changer, enhancing connected worker safety in unprecedented ways. One such tool that leverages the power of IoT to ensure worker safety is FAT FINGER, a digital workflow procedure builder that empowers front-line teams to do their work correctly every time.

Understanding the Power of IoT in High-Risk Industries

In high-risk industries such as mining, construction, manufacturing, or oil and gas, IoT can play a pivotal role in ensuring worker safety. The technology can be utilized to monitor workers and their environment in real-time. This can include tracking the location of workers in a potentially hazardous site, monitoring environmental conditions such as temperature, humidity, or the presence of toxic gases, and even monitoring the health and physical state of the workers themselves such as heart rate or stress levels.

In addition to real-time monitoring, IoT can also be used for predictive maintenance. This involves using the data collected from IoT sensors to predict when equipment or machinery is likely to fail or require maintenance. By identifying these issues in advance, steps can be taken to rectify them before they cause accidents or injuries. This can significantly reduce the risk of equipment-related accidents and improve overall operational efficiency.

Moreover, IoT can enable instant communication, which is especially important in emergency situations. For instance, in the event of an accident or a hazardous situation, IoT devices can send instant alerts to workers, supervisors, or even emergency services. This can help to ensure a swift response, reducing the potential for serious injuries or fatalities.

This technology also has the potential to automate certain tasks that can be dangerous for humans, further enhancing safety. For example, drones equipped with IoT technology can be used to inspect hard-to-reach or hazardous areas, reducing the need for workers to be exposed to these risks.

Therefore, the Internet of Things is not just about interconnectivity and efficiency; it’s also about creating safer and more secure environments, particularly in high-risk industries. Its capabilities for real-time monitoring, predictive maintenance, and instant communication are transforming the way safety is managed, contributing to a significant reduction in workplace accidents and injuries.

How FAT FINGER Enhances Worker Safety with IoT

FAT FINGER leverages IoT to create digital workflows and checklists across safety, maintenance, and operations areas. These include:

- Safety: Take 5 safety, Near miss reporting, JSA / JHA, Risk Assessment, Incident reporting, Journey report

- Operations: Material Inspection, Quality Control, Shift Handover, Facility inspection / Production rounds, Line Changeover, Field ticket

- Maintenance: Work Order Checklist, Truck inspection checks, Mobile Asset Inspection, Shutdown / Turnaround form, Preventive maintenance inspection, Predictive Maintenance

By integrating IoT devices, FAT FINGER can provide real-time data, enabling immediate response to any safety concerns. This not only prevents accidents but also improves overall operational efficiency.

Case Studies: IoT and Worker Safety

Several high-risk industries have already started leveraging IoT for worker safety. For instance, in the mining industry, IoT devices are used to monitor air quality and detect hazardous gases. In the construction industry, wearable IoT devices can alert workers about potential hazards in their vicinity. FAT FINGER, with its IoT integration, can further enhance these safety measures by providing real-time data and actionable insights.

Statistics: The Impact of IoT on Worker Safety

According to a report by Deloitte, companies that have implemented IoT for worker safety have seen a 10-20% reduction in workplace injuries. Furthermore, a study by PwC found that IoT can reduce workplace fatalities by 16%. These statistics clearly highlight the potential of IoT in enhancing worker safety in high-risk industries.

The Future of Worker Safety with IoT

The future of worker safety in high-risk industries lies in the integration of advanced technologies like IoT. With tools like FAT FINGER, companies can not only ensure the safety of their workers but also improve their operational efficiency. As IoT technology continues to evolve, we can expect even more sophisticated safety measures in the future.

Conclusion

The role of IoT in enhancing connected worker safety in high-risk industries is undeniable. By providing real-time monitoring, predictive maintenance, and instant communication, IoT can significantly reduce workplace injuries and fatalities. Tools like FAT FINGER, with their IoT integration, are leading the way in leveraging this technology for worker safety. As we move forward, the integration of IoT in worker safety measures is set to become the norm rather than the exception.

Ready to enhance your worker safety with IoT? Sign up for FAT FINGER or request a demo today to see how our digital workflow procedure builder can empower your front-line teams and ensure their safety.