As technology continues to evolve, businesses are constantly seeking innovative ways to improve efficiency and safety. One such technology that is making significant strides in this regard is Augmented reality (AR). This article will explore how AR, particularly when integrated with a digital workflow procedure builder like FAT FINGER, can provide real-time maintenance guidance, thereby enhancing operational efficiency and safety.

Understanding Augmented Reality (AR)

AR is a technology that overlays digital information onto the real world, providing users with an enhanced version of reality. This technology has found applications in various sectors, including maintenance and operations, where it can provide real-time guidance and support.

Augmented Reality in Maintenance: A Game Changer

AR technology can revolutionize maintenance procedures by providing real-time, step-by-step guidance to technicians. This can significantly reduce the time taken to complete tasks, minimize errors, and improve safety. Here’s how:

- AR can provide visual instructions overlaid on the equipment, guiding technicians through the maintenance process.

- It can help identify potential issues before they become major problems, enabling preventive maintenance.

- AR can provide real-time data about the equipment, helping technicians make informed decisions.

- It can also provide remote assistance, where experts can guide technicians through complex procedures, improving safety and efficiency.

FAT FINGER: Empowering Front-Line Teams with AR

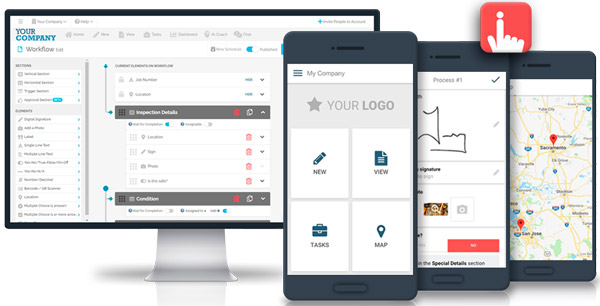

FAT FINGER is a digital workflow procedure builder that empowers front-line teams to do their work correctly every time. It allows you to build checklists, workflows, and digital procedures that unlock operational excellence. One of the key features of FAT FINGER is its integration with AR technology, which can significantly enhance maintenance procedures.

How FAT FINGER Uses AR for Real-Time Maintenance Guidance

FAT FINGER uses AR to provide real-time maintenance guidance, improving efficiency and safety. Here’s how:

- With FAT FINGER’s AR feature, technicians can get visual instructions overlaid on the equipment, guiding them through the maintenance process.

- It can help identify potential issues before they become major problems, enabling preventive maintenance.

- FAT FINGER’s AR can provide real-time data about the equipment, helping technicians make informed decisions.

- It can also provide remote assistance, where experts can guide technicians through complex procedures, improving safety and efficiency.

Case Study: Improving Efficiency and Safety with FAT FINGER’s AR

A leading manufacturing company implemented FAT FINGER’s AR feature for its maintenance procedures. The results were impressive:

- The time taken to complete maintenance tasks was reduced by 30%.

- The error rate in maintenance procedures was reduced by 40%.

- The safety incidents during maintenance procedures were reduced by 50%.

Conclusion

Augmented reality (AR) is a game-changing technology that can significantly improve efficiency and safety in maintenance procedures. When integrated with a digital workflow procedure builder like FAT FINGER, it can provide real-time maintenance guidance, helping technicians do their work correctly every time. With features like visual instructions, preventive maintenance, real-time data, and remote assistance, FAT FINGER’s AR can revolutionize your maintenance procedures.

Ready to unlock operational excellence with FAT FINGER’s AR? Sign up today or request a demo to see how it can transform your maintenance procedures.