Material inspection is a critical aspect of quality control in various industries, ensuring that products meet the required standards and specifications. One of the most common and effective methods of material inspection is visual inspection. This article explores the various visual inspection techniques and tools used in material inspection, with a particular focus on the role of FAT FINGER, a digital workflow procedure builder, in enhancing these processes.

Understanding Visual Inspection

Visual inspection involves the use of the naked eye or visual aids to examine materials for defects or irregularities. It is a non-destructive testing method that can detect surface flaws such as cracks, corrosion, and misalignments. Visual inspection is cost-effective, easy to implement, and provides immediate results, making it a preferred method for many industries.

Visual Inspection Techniques

There are several techniques used in visual inspection, each with its unique advantages and applications. These include:

- Direct visual inspection: This involves the naked eye examination of materials. It is the simplest and most straightforward method.

- Remote visual inspection: This technique uses tools like borescopes and cameras to inspect hard-to-reach areas.

- Automated visual inspection: This involves the use of machine vision systems to automatically inspect materials. It is particularly useful in high-speed production lines.

Visual Inspection Tools

Various tools aid in visual inspection, enhancing accuracy and efficiency. These include magnifying glasses, microscopes, borescopes, and machine vision systems. However, the advent of digital technology has revolutionized visual inspection, introducing tools like FAT FINGER that streamline and automate the process.

The Role of FAT FINGER in Visual Inspection

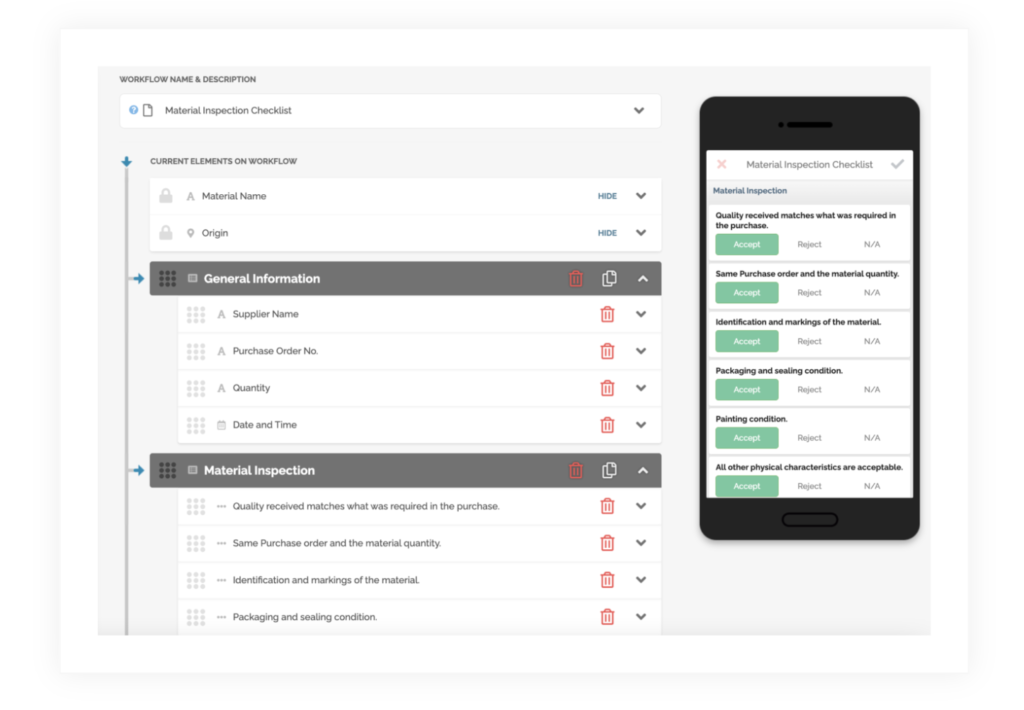

FAT FINGER is a digital workflow procedure builder that empowers front-line teams to do their work correctly every time. It allows you to build checklists, workflows, and digital procedures that unlock operational excellence. FAT FINGER features include a drag & drop workflow builder, mobile & desktop workflows, dashboards, integrations, augmented reality, and artificial intelligence coaching.

In the context of visual inspection, FAT FINGER can be used to create digital workflows and checklists for material inspection. This ensures that the inspection process is standardized, reducing the risk of human error and enhancing the quality of inspection. Furthermore, FAT FINGER’s dashboards provide real-time insights into the inspection process, enabling quick decision-making and continuous improvement.

Case Study: FAT FINGER in Action

A manufacturing company implemented FAT FINGER to streamline its visual inspection process. The company was able to create a standardized checklist for material inspection, ensuring that all inspectors followed the same procedure. The use of FAT FINGER’s dashboards provided real-time insights into the inspection process, enabling the company to identify and address issues promptly. As a result, the company reported a significant reduction in defects and an improvement in product quality.

Conclusion

Visual inspection is a critical aspect of material inspection, ensuring that products meet the required standards and specifications. The use of digital tools like FAT FINGER can significantly enhance the efficiency and effectiveness of visual inspection, providing real-time insights and standardizing the inspection process. By leveraging these tools, companies can ensure the quality of their products, reduce defects, and achieve operational excellence.

Ready to take your visual inspection process to the next level? Sign up for FAT FINGER or request a demo today to see how our digital workflow procedure builder can transform your operations.