As industries continue to evolve, the need for efficient and reliable inspection methods for conductive materials becomes increasingly crucial. One such method that has gained significant traction is Eddy Current Testing (ECT). This non-destructive testing technique is widely used in various industries, including aerospace, automotive, and oil and gas, to detect defects and ensure the integrity of conductive materials. In this context, digital workflow procedure builders like FAT FINGER play a pivotal role in streamlining the inspection process and ensuring operational excellence.

Understanding Eddy Current Testing

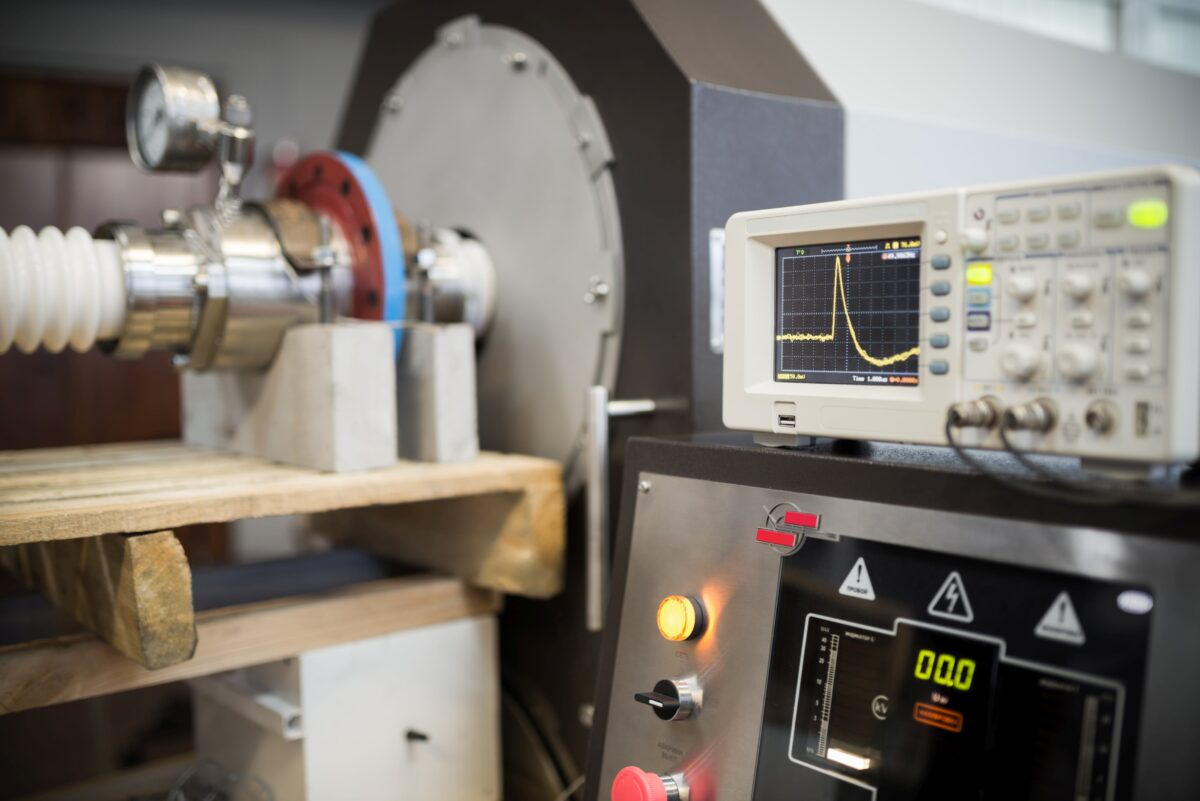

Eddy Current Testing is a non-destructive testing method that uses electromagnetic induction to detect flaws in conductive materials. It is based on the principle of electromagnetic induction, where a changing magnetic field induces an electric current, known as an “eddy current,” in a conductive material.

How Eddy Current Testing Works

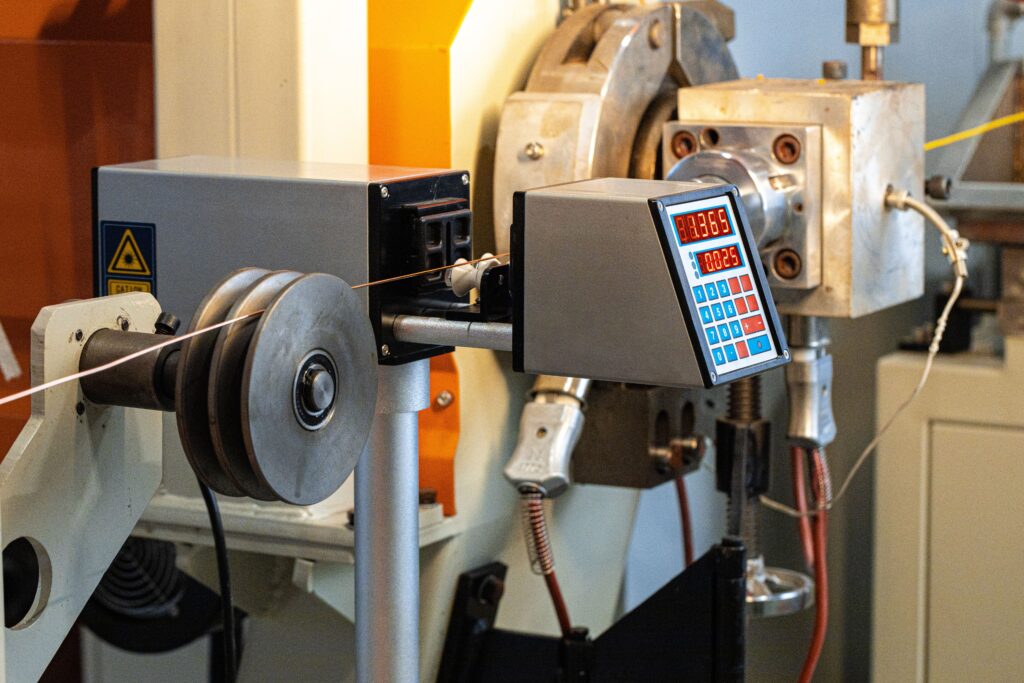

The ECT process involves placing a coil carrying an alternating current near the material to be tested. This creates a changing magnetic field that induces eddy currents in the material. Any change in the material’s properties, such as a crack or corrosion, disrupts these currents. The disruption is detected and analyzed by the testing equipment, providing valuable information about the material’s condition.

Benefits of Eddy Current Testing

- Non-destructive: ECT does not damage or alter the material being tested, making it ideal for inspecting valuable or delicate materials.

- Sensitive to small defects: ECT can detect very small cracks and other defects that may be missed by other testing methods.

- Fast and efficient: ECT can inspect large areas quickly, making it suitable for high-volume production environments.

The Role of FAT FINGER in Eddy Current Testing

FAT FINGER, a digital workflow procedure builder, empowers front-line teams to perform their work correctly every time. It allows you to create checklists, workflows, and digital procedures that unlock operational excellence. In the context of Eddy Current Testing, FAT FINGER can be used to streamline the inspection process.

Material Inspection with FAT FINGER

With FAT FINGER, you can create a digital workflow for the ECT process. This includes a step-by-step guide for conducting the test, a checklist for ensuring all necessary equipment is available and in good condition, and a procedure for analyzing and reporting the test results. This not only ensures that the test is conducted correctly but also makes the process more efficient and reliable.

Quality Control with FAT FINGER

FAT FINGER also plays a crucial role in quality control. The software allows you to track and analyze the results of ECT tests, identify trends, and take corrective action if necessary. This helps maintain the quality of your products and ensures compliance with industry standards.

Conclusion

Eddy Current Testing is a powerful tool for inspecting conductive materials. It is non-destructive, sensitive to small defects, and fast and efficient. However, to fully leverage the benefits of ECT, it is essential to have a robust and reliable workflow in place. This is where FAT FINGER comes in. With its ability to create digital workflows and checklists, FAT FINGER ensures ECT tests are conducted correctly and efficiently every time. Furthermore, its quality control features allow you to maintain the quality of your products and ensure compliance with industry standards.

Ready to take your ECT process to the next level? Get started now by visiting FatFinger.io and explore our range of inspection solutions.