Industrial accidents can have devastating consequences, from loss of life and injury to significant financial costs. One of the most effective ways to prevent these accidents is through the implementation of safety management systems. A prime example of such a system is FAT FINGER, a digital workflow procedure builder that empowers front-line teams to do their work correctly every time.

Understanding Safety Management Systems

Safety management systems are comprehensive, proactive approaches to managing safety and health in the workplace. They involve identifying, assessing, and controlling risks to workers in all types of work environments.

The Importance of Safety Management Systems

Safety management systems are essential tools used in industries to prevent accidents and to ensure the safety and wellbeing of employees. They play a vital role in minimizing the risk of workplace hazards, consequently reducing the occurrence of industrial accidents.

These systems involve creating a structured and systematic approach to managing safety. This means that safety procedures and policies are planned, organized, and implemented in a manner that is consistent and coherent. Such a systemized approach allows for the identification of possible risks and hazards, the assessment of these risks and the development of measures to mitigate them.

A safety management system also provides for the continuous monitoring and review of safety performance. This ensures that safety measures are effective and are being adhered to, and that policies and procedures are updated as necessary to reflect changes in operations, technology or legislation.

By implementing safety management systems, industries can reduce the risk of accidents significantly. This is because potential hazards and risks are identified beforehand and necessary precautions are taken before any mishap occurs. This also allows for a culture of safety to be cultivated within the organization, where safety becomes a priority for all employees.

Furthermore, safety management systems can lead to improved overall safety performance. As safety procedures become more streamlined and effective, the number of accidents, injuries and illnesses can decrease, leading to fewer work stoppages and increased productivity. Additionally, by demonstrating a strong commitment to safety, businesses can improve their reputation among employees, customers, and stakeholders.

How FAT FINGER Enhances Safety Management

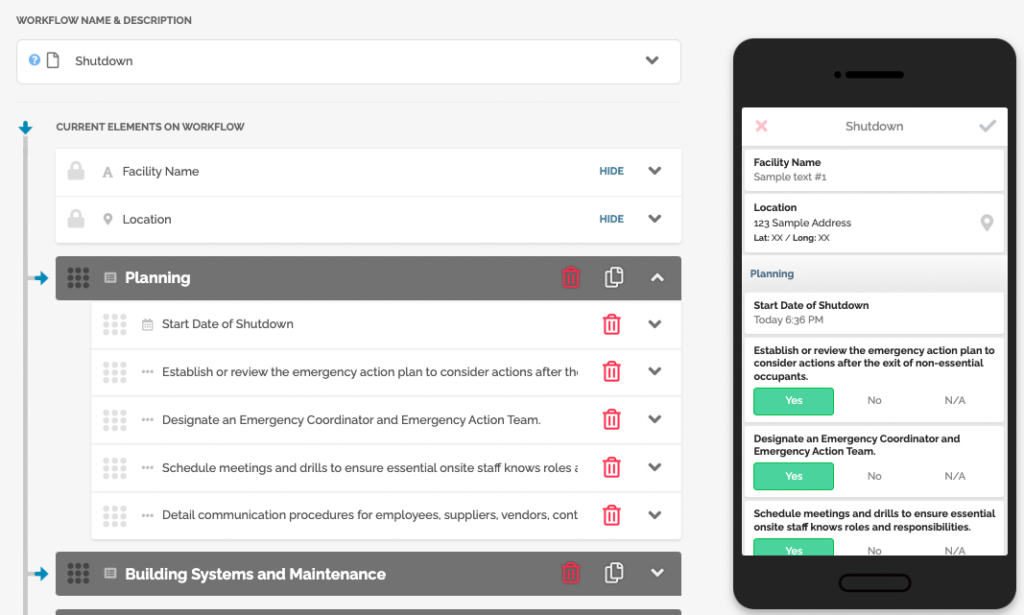

FAT FINGER enhances safety management by allowing you to build checklists, workflows, and digital procedures that unlock operational excellence. Its features include a drag & drop workflow builder, mobile & desktop workflows, dashboards, integrations, augmented reality, connect IoT devices, and artificial intelligence coaching.

Applications of FAT FINGER in Safety, Maintenance, and Operations

You can create FAT FINGER digital workflows and checklists across various safety, maintenance, and operations areas. Here are some of the solutions:

- Safety: Take 5 Safety, Near miss reporting, JSA / JHA, Risk assessment, Incident reporting, Journey report

- Operations: Material Inspection, Quality Control, Shift Handover, Facility inspection / Production rounds, Line Changeover, Field ticket

- Maintenance: Work Order Checklist, Truck inspection checks, Mobile Asset Inspection, Shutdown / Turnaround form, Preventive maintenance inspection, Predictive Maintenance

Case Study: The Impact of Safety Management Systems

A study conducted by the National Safety Council found that companies with safety management systems had injury rates 50% lower than those without. This demonstrates the significant role that safety management systems, like FAT FINGER, can play in preventing industrial accidents.

Conclusion

Industrial accidents can be devastating, but they are preventable. Safety management systems like FAT FINGER play a crucial role in this prevention by providing a structured and systematic approach to managing safety. By implementing such a system, companies can significantly reduce the risk of accidents and improve overall safety performance.

Ready to take the next step in preventing industrial accidents? Sign up for FAT FINGER or request a demo today to see how it can enhance your company’s safety management.