As the world shifts towards renewable energy, wind turbines have become a significant player in the energy sector. However, like any other machinery, wind turbines require regular maintenance to ensure optimal performance. This is where predictive maintenance strategies come into play, and tools like FAT FINGER can be instrumental in implementing these strategies effectively.

Understanding Predictive Maintenance

Predictive maintenance is a proactive approach that uses data analysis and predictive modeling to anticipate when equipment might fail. This allows for timely maintenance, reducing downtime and increasing efficiency. In the context of wind turbines, predictive maintenance can help identify potential issues before they escalate, saving time and resources.

Identifying potential issues before they escalate is a crucial aspect of effective management that helps in saving time and resources. This could involve identifying potential risks in a project, spotting weaknesses in a system, or noticing signs of conflict within a team.

1. Reduces Risk: When potential issues are identified early, steps can be taken to mitigate or completely avoid those risks. This can save a company from potential losses, both in terms of finances and reputation.

2. Saves Time: If problems are detected and dealt with early, it saves the time that would otherwise be spent in dealing with the crisis situation that could develop if the problem was allowed to escalate.

3. Saves Resources: Early problem detection also saves resources. Whether it’s human resources, financial resources, or material resources, preventing a problem from escalating avoids wastage.

4. Increases Efficiency: When potential issues are identified and dealt with promptly, it boosts the efficiency of the team or the system. It reduces downtime and allows for smoother operations.

5. Enhances Planning: Identifying potential problems ahead of time can help in better planning and decision making. It allows for contingency plans to be put in place.

6. Boosts Confidence: A system or team that is capable of identifying and addressing issues promptly tends to boost confidence among stakeholders, including employees, investors, and customers.

7. Improves Adaptability: This proactive approach helps businesses adapt to changes more easily. When potential issues are identified, it can also help point out areas where change is needed.

The Role of FAT FINGER in Predictive Maintenance

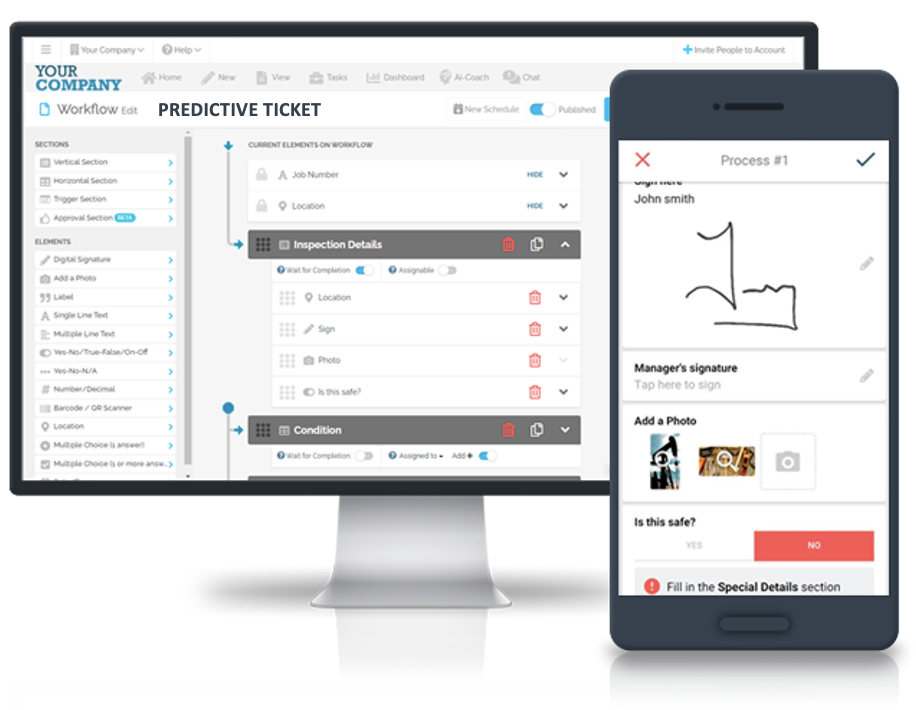

FAT FINGER is a digital workflow procedure builder that empowers front-line teams to do their work correctly every time. It allows you to build checklists, workflows, and digital procedures that unlock operational excellence. With features like Drag & Drop Workflow Builder, Mobile & Desktop Workflows, Dashboards, Integrations, Augmented Reality, Connect IoT Devices, and Artificial Intelligence Coaching, FAT FINGER can be a game-changer in implementing predictive maintenance strategies for wind turbines.

How FAT FINGER Facilitates Predictive Maintenance

FAT FINGER offers solutions across safety, maintenance, and operations areas. Here are some ways it can facilitate predictive maintenance:

- Work Order Checklist: FAT FINGER allows you to create a comprehensive work order checklist, ensuring that all maintenance tasks are performed systematically and nothing is overlooked.

- Mobile Asset Inspection: With FAT FINGER, you can conduct mobile asset inspections, making it easier to monitor and maintain wind turbines.

- Preventive Maintenance Inspection: FAT FINGER’s preventive maintenance inspection feature allows for regular checks, helping to identify potential issues before they become major problems.

- Predictive Maintenance: FAT FINGER’s predictive maintenance feature uses data analysis and predictive modeling to anticipate when a wind turbine might need maintenance, reducing downtime and increasing efficiency.

Case Study: FAT FINGER in Action

A wind energy company implemented FAT FINGER’s predictive maintenance strategies and saw a significant reduction in turbine downtime. By identifying potential issues before they escalated, the company was able to perform timely maintenance, saving time and resources. This case study demonstrates the effectiveness of FAT FINGER’s predictive maintenance strategies in the wind energy sector.

Conclusion

Predictive maintenance strategies for wind turbines can be a game-changer in the energy sector. By anticipating potential issues and performing timely maintenance, these strategies can reduce downtime and increase efficiency. Tools like FAT FINGER, with its comprehensive features and solutions, can be instrumental in implementing these strategies effectively. Whether it’s creating a work order checklist, conducting mobile asset inspections, or using data analysis for predictive maintenance, FAT FINGER empowers front-line teams to do their work correctly every time.

Ready to unlock operational excellence with FAT FINGER? Sign up today or request a demo to see how FAT FINGER can revolutionize your maintenance strategies.