As the world continues to evolve technologically, the energy sector is not left behind. One of the most significant technological advancements that have revolutionized this sector is the Internet of Things (IoT). This article explores the role of IoT in enhancing energy sector productivity, with a particular focus on how FAT FINGER, a digital workflow procedure builder, is contributing to this transformation.

Understanding IoT in the Energy Sector

The Internet of Things (IoT) refers to the network of physical devices, vehicles, appliances, and other items embedded with sensors, software, and network connectivity, which enables these objects to connect and exchange data. In the energy sector, IoT has become a game-changer, providing solutions to enhance productivity, efficiency, and safety.

How IoT Enhances Productivity in the Energy Sector

IoT has a significant impact on the energy sector’s productivity in several ways:

- Real-time Monitoring and Control: IoT devices provide real-time data, enabling energy companies to monitor and control their operations effectively. This real-time data can help identify issues early, preventing costly downtime and improving productivity.

- Predictive Maintenance: IoT devices can predict potential equipment failures before they occur, allowing for timely maintenance and reducing unplanned downtime.

- Energy Efficiency: IoT devices can optimize energy use, reducing waste and improving efficiency. This not only saves costs but also contributes to sustainability efforts.

- Safety and Compliance: IoT can enhance safety by monitoring hazardous conditions and alerting workers to potential risks. It can also help companies comply with regulatory requirements by providing accurate, real-time data.

The Role of FAT FINGER in IoT and Energy Sector Productivity

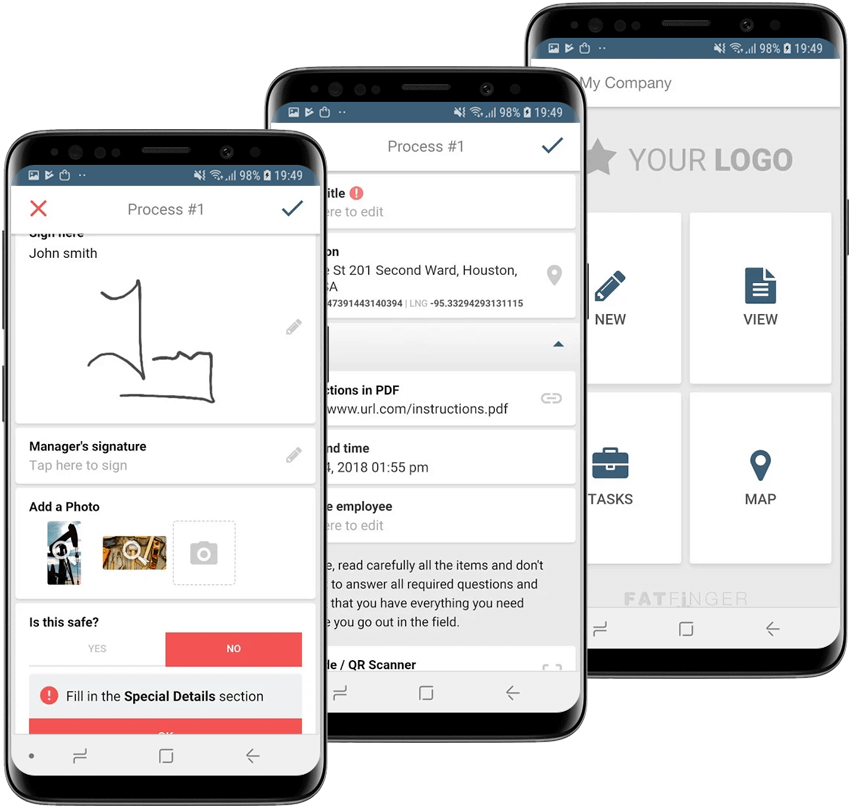

FAT FINGER is a digital workflow procedure builder that empowers front-line teams to do their work correctly every time. It allows you to build checklists, workflows, and digital procedures that unlock operational excellence. FAT FINGER features include a drag & drop workflow builder, mobile & desktop workflows, dashboards, integrations, augmented reality, and the ability to connect IoT devices.

With FAT FINGER, energy companies can create digital workflows and checklists across safety, maintenance, and operations areas. These include safety take 5, near miss reporting, risk assessment, incident reporting, journey report, material inspection, quality control, shift handover, facility inspection, line changeover, field ticket, work order checklist, truck inspection checks, mobile asset inspection, shutdown/turnaround form, preventive maintenance inspection, and predictive maintenance.

Case Study: IoT and FAT FINGER in Action

One example of IoT and FAT FINGER in action in the energy sector is a leading oil and gas company that implemented IoT devices to monitor their equipment’s performance. They used FAT FINGER to create digital workflows and checklists for their maintenance team. This allowed them to predict potential equipment failures, perform timely maintenance, and reduce unplanned downtime. As a result, they saw a significant increase in their productivity and efficiency.

Conclusion

The role of IoT in enhancing energy sector productivity cannot be overstated. From real-time monitoring and control to predictive maintenance, energy efficiency, and safety and compliance, IoT is revolutionizing the energy sector. And with tools like FAT FINGER, companies can leverage IoT to its full potential, unlocking operational excellence and enhancing productivity.

Are you ready to take your energy company to the next level with IoT and FAT FINGER? Sign up for FAT FINGER or request a demo today to see how we can help you enhance your productivity and efficiency.