As the energy sector continues to evolve, the need for efficient and effective maintenance strategies has never been more critical. One solution that is rapidly gaining traction is the use of Artificial Intelligence (AI) for predictive maintenance. This approach, when combined with the power of FAT FINGER, a digital workflow procedure builder, can revolutionize the way energy facilities operate.

Understanding Predictive Maintenance

Predictive maintenance refers to the use of data-driven, proactive maintenance strategies that predict when equipment failure might occur. This approach allows for timely intervention, reducing downtime and increasing operational efficiency. It’s a significant shift from traditional reactive or scheduled maintenance methods.

The Role of AI in Predictive Maintenance

AI plays a crucial role in predictive maintenance by analyzing vast amounts of data to identify patterns and predict potential failures. This process involves machine learning algorithms that learn from historical and real-time data, making accurate predictions about equipment health and lifespan.

Benefits of Implementing AI for Predictive Maintenance

- Reduced downtime: By predicting failures before they occur, facilities can schedule maintenance during non-peak hours, minimizing disruption.

- Increased operational efficiency: Predictive maintenance helps optimize the use of resources, reducing unnecessary maintenance tasks and focusing on areas that need attention.

- Improved safety: Predicting and preventing equipment failures can significantly reduce the risk of accidents and improve overall safety.

- Cost savings: By preventing unexpected equipment failures and optimizing maintenance tasks, facilities can achieve substantial cost savings.

Case Study: AI and Predictive Maintenance in Action

A leading energy company implemented AI for predictive maintenance and saw a 20% reduction in maintenance costs and a 15% decrease in downtime. The AI system was able to predict potential failures up to two weeks in advance, allowing for timely intervention and prevention of costly breakdowns.

How FAT FINGER Enhances AI-Powered Predictive Maintenance

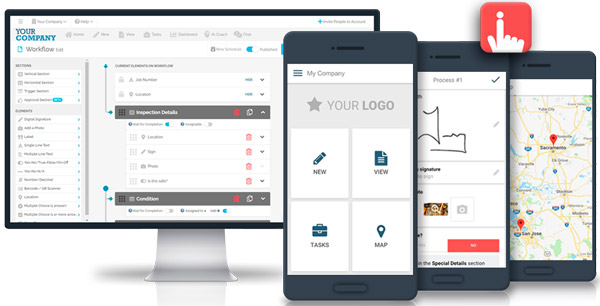

FAT FINGER empowers front-line teams to do their work correctly every time by allowing you to build checklists, workflows, and digital procedures that unlock operational excellence. Its features include a drag & drop workflow builder, mobile & desktop workflows, dashboards, integrations, augmented reality, and the ability to connect IoT devices.

When it comes to predictive maintenance, FAT FINGER’s AI coaching feature can be a game-changer. It can guide teams through the maintenance process, ensuring that every step is followed correctly and efficiently. This feature, combined with the ability to create digital workflows and checklists for predictive maintenance, can significantly enhance the effectiveness of your predictive maintenance strategy.

Conclusion

Implementing AI for predictive maintenance in energy facilities can bring about significant benefits, including reduced downtime, increased operational efficiency, improved safety, and substantial cost savings. When combined with the power of FAT FINGER, these benefits can be further enhanced, leading to truly transformative results.

Ready to revolutionize your maintenance strategy? Sign up for FAT FINGER or request a demo today to see how our digital workflow procedure builder can empower your front-line teams and unlock operational excellence.