As technology continues to evolve, industries are finding innovative ways to improve their operations and training methods. One such technological advancement that is making waves in the industrial sector is Augmented Reality (AR). This technology is being leveraged by companies like FAT FINGER, a digital workflow procedure builder, to empower front-line teams to perform their tasks correctly every time.

Understanding Augmented Reality

Augmented Reality is a technology that overlays digital information onto the real world, enhancing the user’s perception and interaction with their environment. It can be used to provide real-time information, display 3D models, and offer interactive training experiences.

Augmented Reality in Industrial Training

AR is revolutionizing industrial training in several ways. It provides a hands-on learning experience, reduces training time, and improves safety. Here are some ways AR is being used in industrial training:

- Interactive Training: AR allows trainees to interact with a virtual representation of the machinery or equipment they will be working with. This interactive training helps them understand the workings of the equipment better.

- Reduced Training Time: With AR, trainees can learn at their own pace. They can repeat the training as many times as they need, reducing the overall training time.

- Improved Safety: AR can simulate dangerous situations, allowing trainees to learn how to handle them without any real-world risk.

Case Study: FAT FINGER and Augmented Reality

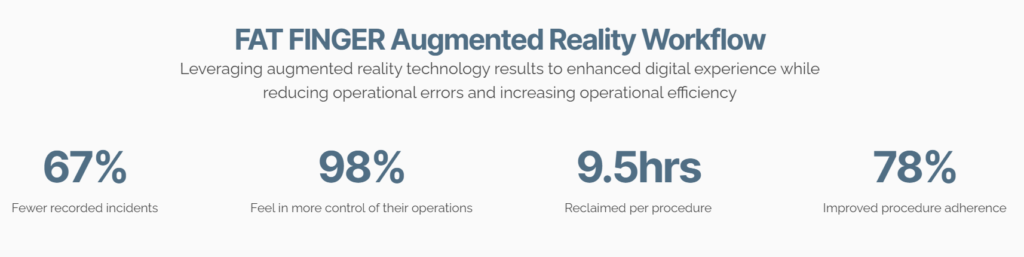

FAT FINGER is at the forefront of integrating AR into industrial training. Their software allows companies to build checklists, workflows, and digital procedures that unlock operational excellence. With features like a drag & drop workflow builder, mobile & desktop workflows, dashboards, integrations, AR, IoT device connectivity, and artificial intelligence coaching, FAT FINGER is revolutionizing the way industries train their workforce.

For instance, FAT FINGER’s AR feature allows trainees to visualize complex procedures in a 3D environment. This not only enhances their understanding but also ensures they perform their tasks correctly every time.

The Future of AR in Industrial Training

With the success of AR in industrial training, its future looks promising. According to a report by Grand View Research, the global AR market size is expected to reach $340.16 billion by 2028, growing at a compound annual growth rate (CAGR) of 43.8% from 2021 to 2028. This growth is likely to be driven by the increasing adoption of AR in industrial training.

Conclusion

The rise of Augmented Reality in industrial training is a testament to the transformative power of technology. By providing interactive, safe, and efficient training, AR is set to revolutionize industrial training. Companies like FAT FINGER are leading the way, integrating AR into their digital workflow procedure builders to empower front-line teams.

Are you ready to leverage the power of AR for your industrial training? Sign up for FAT FINGER or request a demo today to see how their software can transform your training methods and improve operational excellence.