In the era of Industry 4.0, machine learning is revolutionizing the way businesses operate, particularly in the realm of production efficiency. One such tool that is leading the charge in this digital transformation is FAT FINGER, a digital workflow procedure builder that empowers front-line teams to perform their tasks correctly every time.

Understanding Machine Learning

Machine learning, a subset of artificial intelligence, involves the use of algorithms and statistical models to perform tasks without explicit instructions. It relies on patterns and inference instead. This technology is increasingly being used in production environments to improve efficiency and productivity.

How Machine Learning Enhances Production Efficiency

Machine learning can significantly enhance production efficiency in several ways:

- Predictive Maintenance: Machine learning algorithms can predict equipment failures before they occur, reducing downtime and maintenance costs.

- Quality Control: Machine learning can identify defects and quality issues in real-time, improving product quality and reducing waste.

- Supply Chain Optimization: Machine learning can forecast demand and optimize inventory, reducing stockouts and overstock situations.

- Process Optimization: Machine learning can identify inefficiencies in production processes and suggest improvements.

Case Study: FAT FINGER and Machine Learning

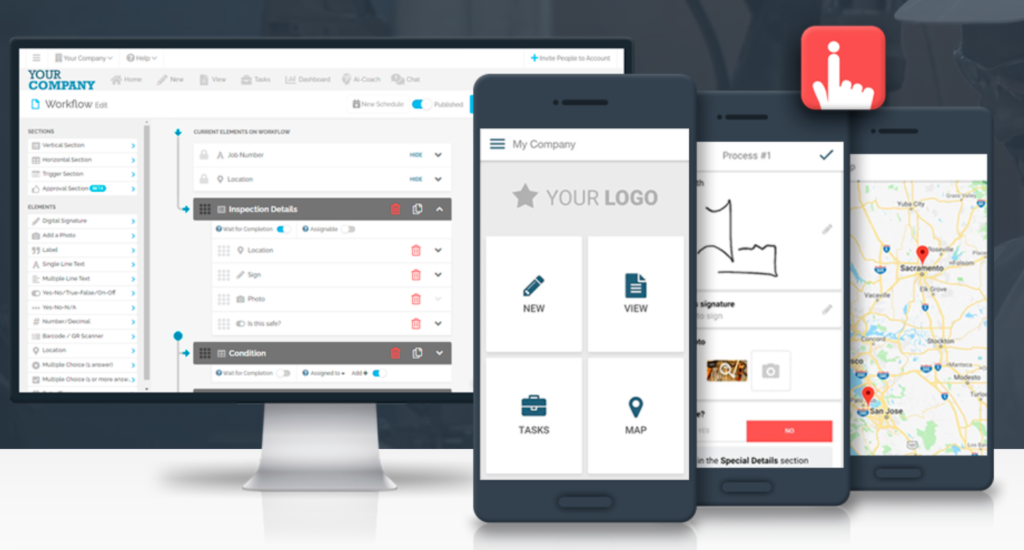

FAT FINGER is a prime example of how machine learning can be leveraged to improve production efficiency. With features like a drag & drop workflow builder, mobile & desktop workflows, dashboards, integrations, augmented reality, IoT device connectivity, and artificial intelligence coaching, FAT FINGER is transforming the way businesses operate.

For instance, FAT FINGER’s artificial intelligence coaching feature uses machine learning to guide users through complex procedures, reducing errors and improving efficiency. Its predictive analytics capabilities can also help businesses anticipate and address potential issues before they become problems, further enhancing productivity.

Statistics Highlighting the Impact of Machine Learning

According to a report by McKinsey, machine learning can reduce supply chain forecasting errors by up to 50% and reduce lost sales due to product unavailability by up to 65%. Furthermore, a study by Accenture found that predictive maintenance could reduce maintenance costs by up to 30%, increase production by up to 25%, and improve uptime by up to 20%.

Conclusion

Machine learning is a powerful tool that can significantly enhance production efficiency. By predicting equipment failures, improving quality control, optimizing supply chains, and streamlining processes, machine learning can help businesses save time, reduce costs, and increase productivity. Tools like FAT FINGER are at the forefront of this revolution, providing businesses with the technology they need to unlock operational excellence.

If you’re ready to harness the power of machine learning to improve your production efficiency, sign up for FAT FINGER or request a demo today.