As the world becomes increasingly interconnected, the intersection of connected work and environmental sustainability in turnarounds is becoming more critical. This is where FAT FINGER, a digital workflow procedure builder, comes into play. FAT FINGER empowers front-line teams to do their work correctly every time, unlocking operational excellence through its comprehensive features.

Connected Work and Environmental Sustainability: A Crucial Intersection

Connected work refers to the use of digital tools and platforms to facilitate collaboration and streamline operations. On the other hand, environmental sustainability involves practices that promote the long-term health of our planet. The intersection of these two concepts in turnarounds—periods of planned shutdowns for maintenance or upgrades—is crucial for several reasons.

- Efficiency: Connected work tools like FAT FINGER can streamline turnaround processes, reducing downtime and minimizing waste.

- Accuracy: Digital workflows and checklists ensure tasks are completed correctly, reducing the risk of errors that could lead to environmental harm.

- Accountability: With digital tracking, companies can easily monitor and report on their environmental impact during turnarounds.

Case Study: FAT FINGER in Action

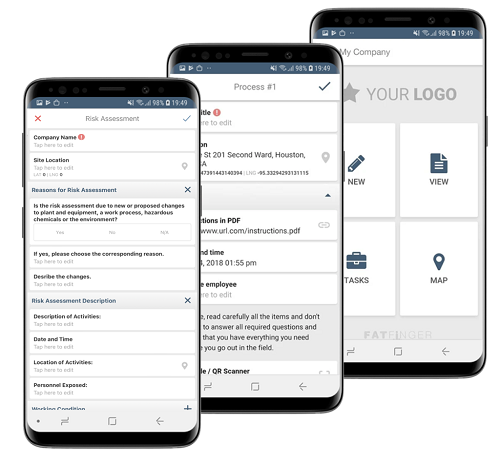

One of the best ways to understand the intersection of connected work and environmental sustainability in turnarounds is to look at FAT FINGER in action. This software offers solutions across safety, operations, and maintenance, including work order checklists, quality control, and predictive maintenance.

For instance, during a turnaround, a company can use FAT FINGER’s Shutdown/Turnaround form to manage tasks efficiently. This not only reduces downtime but also minimizes waste, contributing to environmental sustainability. Moreover, the software’s predictive maintenance feature can help prevent equipment failures that could lead to environmental harm.

Statistics Highlighting the Importance of Connected Work in Turnarounds

Digital solutions can reduce turnaround time by up to 25%. This not only translates to significant cost savings but also minimizes the environmental impact of shutdowns. Furthermore, predictive maintenance—like that offered by FAT FINGER—can reduce equipment downtime by 30-50% and increase equipment lifespan by 20-40%.

Conclusion: The Future of Turnarounds is Digital and Sustainable

The intersection of connected work and environmental sustainability in turnarounds is not just a trend—it’s the future. Digital tools like FAT FINGER are revolutionizing turnarounds, making them more efficient, accurate, and environmentally friendly. By leveraging these tools, companies can not only improve their bottom line but also contribute to the long-term health of our planet.

Ready to experience the benefits of connected work in your turnarounds? Sign up for FAT FINGER or request a demo today.