In the heavy industry sector, shutdowns are a necessary but costly part of operations. However, with the advent of digital workflow procedure builders like FAT FINGER, companies can leverage connected work to gain a competitive advantage during these shutdown periods. FAT FINGER empowers front-line teams to do their work correctly every time, unlocking operational excellence through checklists, workflows, and digital procedures.

Understanding the Impact of Shutdowns in Heavy Industry

Shutdowns, also known as turnarounds, are planned periods of non-production where routine maintenance, repairs, and inspections take place. While necessary for safety and efficiency, these periods can be costly due to lost production time and the resources required to carry out the work.

The Role of Connected Work in Shutdowns

Connected work refers to the use of digital tools and platforms to streamline and enhance collaboration and communication among teams. In the context of heavy industry shutdowns, connected work can help to reduce downtime, improve efficiency, and ensure that all tasks are carried out correctly and safely.

How FAT FINGER Enhances Connected Work During Shutdowns

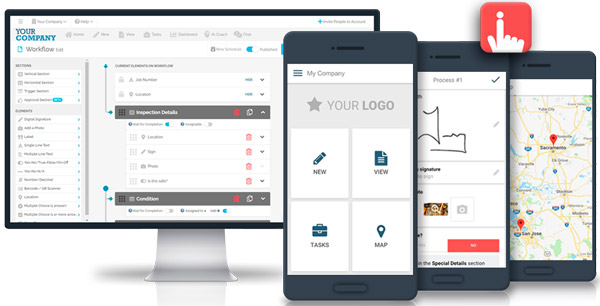

FAT FINGER is a digital workflow procedure builder that offers a range of features designed to empower front-line teams and improve operational efficiency. These include:

- Drag & Drop Workflow Builder

- Mobile & Desktop Workflows

- Dashboards

- Integrations

- Augmented Reality

- Connect IoT Devices

- Artificial Intelligence Coaching

These features can be used to create digital workflows and checklists across safety, maintenance, and operations areas, including:

- Safety: Take 5 Safety, Near miss reporting, JSA / JHA, Risk Assessment, Incident reporting, Journey report

- Operations: Material Inspection, Quality Control, Shift Handover, Facility inspection / Production rounds, Line Changeover, Field ticket

- Maintenance: Work Order Checklist, Truck inspection checks, Mobile Asset Inspection, Shutdown / Turnaround form, Preventive maintenance inspection, Predictive Maintenance

Conclusion: The Competitive Advantage of Connected Work

In conclusion, leveraging connected work during heavy industry shutdowns can provide a significant competitive advantage. By using digital workflow procedure builders like FAT FINGER, companies can reduce downtime, improve efficiency, and ensure safety, ultimately leading to cost savings and improved operational excellence.

If you’re interested in leveraging the power of connected work in your heavy industry operations, consider signing up for FAT FINGER or requesting a demo today. With FAT FINGER, you can empower your front-line teams to do their work correctly every time, unlocking the potential for operational excellence in your organization.