The oil and gas industry is a complex and challenging environment, where efficiency, safety, and sustainability are paramount. In this context, digital transformation is not just a buzzword, but a necessity. One such digital solution that is making waves in the industry is FAT FINGER, a digital workflow procedure builder that empowers front-line teams to do their work correctly every time.

Efficiency in Oil and Gas Operations

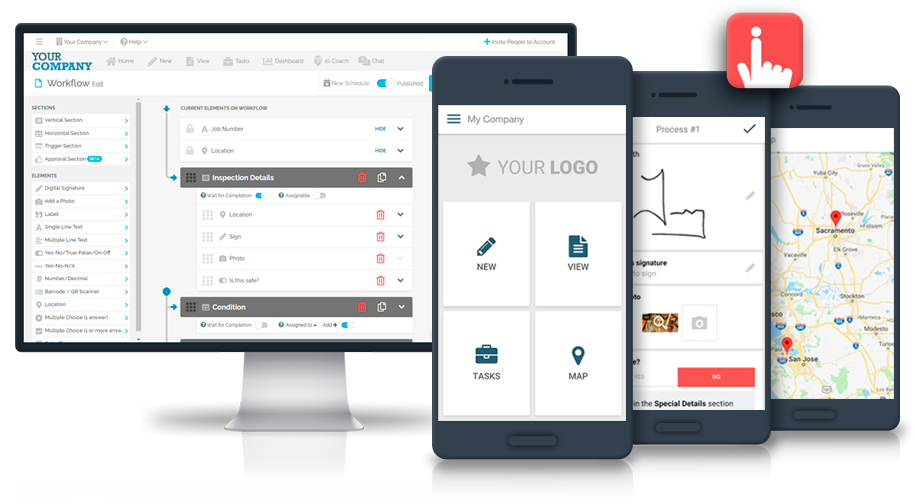

Efficiency is a critical factor in the oil and gas industry. With FAT FINGER, companies can streamline their operations with features like Drag & Drop Workflow Builder, Mobile & Desktop Workflows, and Dashboards. These tools allow for real-time data collection and analysis, leading to improved decision-making and operational efficiency.

Case Study: A leading oil and gas company used FAT FINGER to digitize their field ticketing process, resulting in improved operational efficiency.

Safety in the Oil and Gas Industry

Safety is a non-negotiable aspect of the oil and gas industry. FAT FINGER’s safety solutions like Take 5 Safety, Near miss reporting, JSA / JHA, Risk Assessment, and Incident reporting, help companies maintain a safe working environment. These digital workflows and checklists ensure that safety protocols are followed meticulously, reducing the risk of accidents and injuries.

Statistics: According to a report by the International Association of Oil & Gas Producers, companies that implemented digital safety solutions saw a 20% reduction in workplace accidents.

Sustainability in the Oil and Gas Sector

Sustainability is becoming increasingly important in the oil and gas sector. FAT FINGER’s features like Connect IoT Devices and Artificial Intelligence Coaching can help companies reduce their environmental impact. For instance, IoT devices can monitor and control emissions, while AI can optimize energy use.

Example: A major oil company used FAT FINGER’s IoT connectivity to monitor and reduce its greenhouse gas emissions, contributing to its sustainability goals.

Conclusion: The Power of Connected Work

Connected work in the oil and gas industry, enabled by digital solutions like FAT FINGER, can balance efficiency, safety, and sustainability. By digitizing workflows and procedures, companies can streamline operations, enhance safety, and contribute to a sustainable future. The power of connected work lies in its ability to transform complex processes into simple, manageable tasks, empowering front-line teams to do their work correctly every time.

Ready to experience the power of connected work in your oil and gas operations? Sign up for FAT FINGER or request a demo today.