The oil and gas industry is the cornerstone of the global economy, providing the primary energy source for a wide array of applications, from transportation to heating and electricity generation.

However, it’s an industry that faces a unique set of challenges. These challenges include environmental concerns, market volatility, and safety issues, all of which necessitate a thoughtful approach to process improvement.

Challenges in Oil and Gas Industry

Before we delve into process improvement, let’s first explore the main challenges in the Oil and Gas Industry.

Environmental Concerns

Environmental sustainability is a pressing concern in the oil and gas industry. The extraction and processing of fossil fuels can have adverse effects on the environment. To address this, companies are constantly seeking ways to reduce their carbon footprint.

Process improvement plays a vital role in achieving this by

- Optimizing processes to minimize emissions

- Reducing the industry’s overall ecological impact.

This not only meets regulatory requirements but also demonstrates a commitment to environmental responsibility.

Market Volatility

Oil prices can be unpredictable, making financial planning a significant challenge for oil and gas companies. Market volatility can have a direct impact on profitability. Through process improvement, companies can:

- Better manage their costs

- Enhance overall operational efficiency

- Adapt more effectively to fluctuating market conditions

- Maintain profitability even when oil prices are turbulent

Safety Issues

Safety is paramount in the oil and gas sector due to the hazardous nature of the work involved. From oil rig operations to transportation and refining processes, safety is a primary concern.

Process improvement isn’t just about cost savings; it’s also about creating safer working environments. Companies that invest in process improvement can experience the following:

- Significantly reduce the risk of accidents

- Protect their employees

- Minimize the potential for environmental disasters

Why Process Improvement?

Reducing costs, enhancing efficiency and adherence to quality are some of the benefits you can derive from process improvement. Let’s look at these benefits in more detail:

Cost Reduction

In an industry where profitability is closely tied to market prices, cost reduction is a critical factor in ensuring the financial health of an organization. Efficient processes lead to reduced operational expenses, which directly impact a company’s bottom line.

Efficiency Enhancement

Efficiency is the hallmark of successful process improvement. By fine-tuning operations, tasks are completed faster, with fewer errors and less waste. Improved efficiency translates to the following:

- Increased productivity

- Shorter project timelines

- A competitive edge in the industry

The savings in time and resources can be reinvested into further improvements or exploration of new opportunities.

Quality Assurance

With the enormous investment required for exploration, drilling, and production, the quality of the final product must be top-notch.

Through process improvement, companies can implement strict quality control measures to ensure that their products consistently meet industry standards, thereby safeguarding their reputation and enhancing customer trust and loyalty.

Key Steps in Process Improvement

Data Collection and Analysis

Process improvement begins with data. Companies must collect and analyze data to identify areas that need enhancement.

This data may encompass information related to the following areas:

- Operational efficiency

- Equipment performance

- Safety incidents, and more

Advanced data analytics tools help in making sense of the vast amounts of data generated by oil and gas operations.

Identifying Bottlenecks

Bottlenecks are points in the process where the flow of work is impeded, leading to delays and inefficiencies. Whether it’s a logistical challenge, equipment downtime, or human error, identifying these bottlenecks enables companies to develop targeted solutions that optimize the entire process.

Implementing Technological Solutions

Automation, data analytics, and remote monitoring are just a few examples of how technology can streamline operations in the oil and gas industry. For instance, predictive maintenance, powered by sensors and data analytics, can identify equipment issues before they lead to downtime, saving companies millions and increasing reliability.

Best Practices in the Oil and Gas Industry

Continuous Training

Providing ongoing training to employees is crucial to keep them updated on the latest industry best practices. It ensures that they can adapt to new and improved processes, adhere to safety regulations, and operate equipment effectively.

Regulatory Compliance

Adhering to environmental regulations and industry standards is essential for long-term sustainability and public trust. Companies must remain vigilant to evolving regulatory requirements and ensure that their processes comply. Failure to do so can result in legal issues, reputational damage, and operational setbacks.

Stakeholder Collaboration

Collaboration with stakeholders is integral to the success of process improvement efforts.

In the oil and gas industry, stakeholders include government bodies, local communities, and environmental organizations.

Engaging with these groups in an open and transparent manner not only helps in addressing concerns but also builds trust and a positive public image. Collaborative efforts can lead to mutually beneficial solutions and smooth operational processes.

The Role of Technology in Process Improvement

IoT and Sensors

The Internet of Things (IoT) and sensor technology have revolutionized the oil and gas industry. Sensors placed throughout facilities and equipment provide real-time data on operational conditions.

This data is invaluable for making informed decisions and quickly responding to issues. Whether it’s monitoring equipment health, detecting leaks, or optimizing energy consumption, IoT and sensors are instrumental in improving processes and reducing downtime.

AI and Machine Learning

Artificial intelligence (AI) and machine learning have taken data analysis to the next level. These technologies can process vast amounts of data, identifying patterns and suggesting process improvements that may not be apparent to humans.

For example, AI algorithms can predict when a piece of equipment is likely to fail, allowing for preventive maintenance. Machine learning can optimize production schedules, ensuring that resources are allocated efficiently. These technologies provide a competitive advantage to companies that embrace them.

The Bottom Line

Process improvement is not merely an option but a necessity for the oil and gas industry. It is a multifaceted approach that does the following:

- Addresses environmental concerns

- Manages market volatility

- Enhances safety

- Reduces costs

- Improves efficiency

- Ensures quality

The successful implementation of process improvement initiatives sets the stage for sustainable growth, innovation, and long-term success in an industry marked by its complexities and challenges.

Process Improvement FAQs

1. How can process improvement reduce environmental impact in the oil and gas industry?

Process improvement can lead to the development of cleaner and more efficient processes, reducing emissions and the industry’s environmental footprint. This can be achieved through the use of eco-friendly technologies and stringent ecological management practices.

2. What are some common bottlenecks in the oil and gas sector that process improvement can address?

Common bottlenecks include equipment breakdowns, logistical delays in the supply chain, and inefficient operational practices. Process improvement identifies these bottlenecks and offers strategies to mitigate them, leading to streamlined operations.

3. How does technology, like IoT and AI, impact process improvement in the industry?

Technology, such as the Internet of Things (IoT) and Artificial Intelligence (AI), plays a significant role in process improvement by providing real-time data and predictive analysis. IoT sensors monitor equipment health, while AI identifies patterns and offers insights for more efficient operations.

4. What are some of the challenges in implementing process improvement in the oil and gas industry?

Challenges in implementing process improvement can include:

- Resistance to change among employees.

- The high cost of technology adoption.

- The need for specialized training.

Overcoming these challenges requires a strategic approach and commitment from leadership.

5. How can companies in the oil and gas industry collaborate with local communities for process improvement?

Collaboration with local communities can involve open communication, addressing community concerns, and participating in local initiatives that benefit both the industry and the community. This engagement fosters positive relationships and can lead to mutually beneficial solutions.

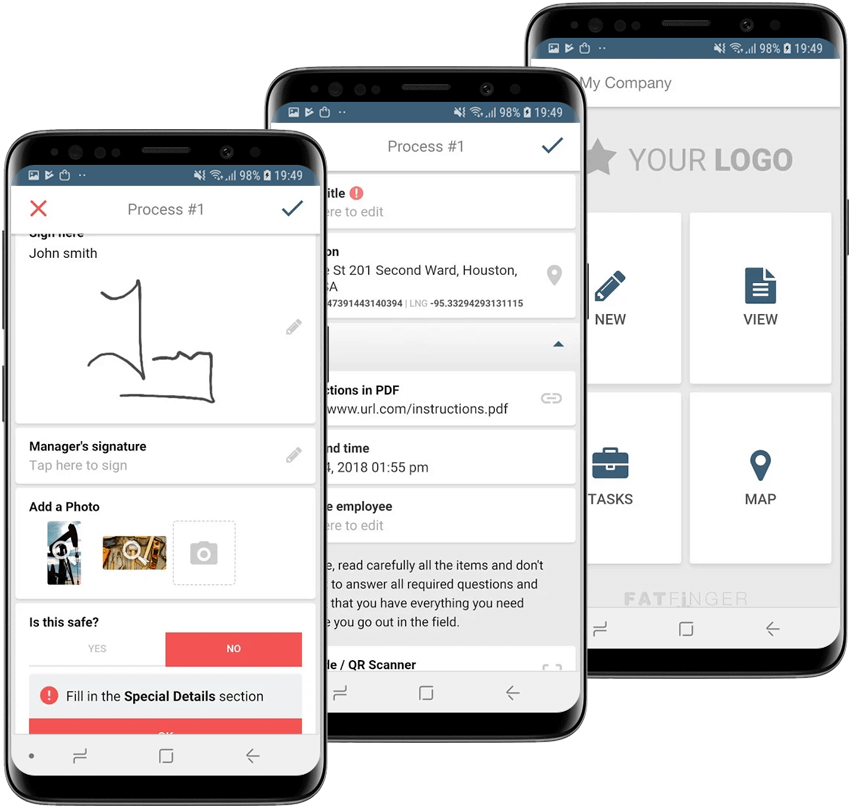

Process Improvement with FAT FINGER

Process improvement saves costs and creates safer working environments. Digitize process improvement at your company with FAT FINGER and experience the following:

- Significantly reduce the risk of accidents

- Protect your employees

- Minimize the potential for environmental disasters

- Enhance process efficiency

- Ensure Quality Control

Why Use FAT FINGER

FAT FINGER has the following benefits:

Easy-to-use interface: This allows your workers to easily and accurately document repairs and maintenance.

Data-Driven Insights: The software generates comprehensive reports and visualizations, empowering organizations to make informed decisions.

Integrated Workflows: This ensures a cohesive approach to safety and operational excellence.

Real-Time Collaboration: Your team can communicate instantly through FAT FINGER, leading to faster response times and better collaboration.