Lean manufacturing is a production philosophy that aims to reduce waste and improve efficiency. It has been widely adopted by many industries, including automotive, aerospace, and electronics. But what is the real impact of lean manufacturing on reducing production costs and enhancing quality? This article will explore this topic in depth, with a particular focus on how digital workflow procedure builders like FAT FINGER can help facilitate lean manufacturing processes.

Understanding Lean Manufacturing

Lean manufacturing is a systematic approach to identifying and eliminating waste through continuous improvement. It aims to produce high-quality products efficiently and quickly by optimizing the flow of materials and information.

Reducing Production Costs with Lean Manufacturing

One of the primary benefits of lean manufacturing is its potential to significantly reduce production costs. This is achieved through several key strategies:

- Eliminating waste: Lean manufacturing focuses on eliminating all forms of waste, including overproduction, waiting time, transportation, processing, inventory, motion, and defects.

- Improving efficiency: By streamlining processes and eliminating unnecessary steps, lean manufacturing can significantly improve efficiency and productivity.

- Reducing inventory: Lean manufacturing encourages just-in-time production, which can significantly reduce inventory costs.

Enhancing Quality with Lean Manufacturing

Lean manufacturing also has a significant impact on product quality. By focusing on continuous improvement and eliminating waste, it helps ensure that products are produced to the highest possible standards. Here’s how:

- Reducing defects: Lean manufacturing techniques such as error-proofing and root cause analysis can help reduce defects and improve product quality.

- Improving process control: Lean manufacturing emphasizes process control and standardization, which can help ensure consistent product quality.

- Enhancing customer satisfaction: By producing high-quality products efficiently and quickly, lean manufacturing can enhance customer satisfaction and loyalty.

Case Study: The Role of FAT FINGER in Lean Manufacturing

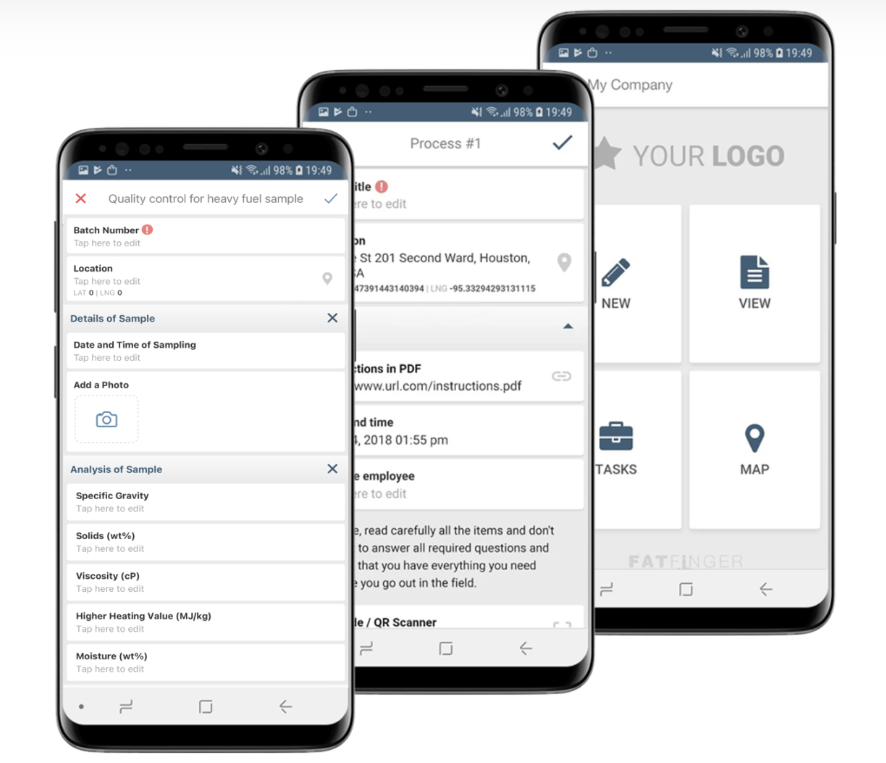

FAT FINGER is a digital workflow procedure builder that empowers front-line teams to do their work correctly every time. It allows you to build checklists, workflows, and digital procedures that unlock operational excellence. FAT FINGER features include a drag & drop workflow builder, mobile & desktop workflows, dashboards, integrations, augmented reality, and artificial intelligence coaching.

By using FAT FINGER, companies can create digital workflows and checklists across safety, maintenance, and operations areas. This can significantly enhance the implementation of lean manufacturing principles by providing a structured and standardized approach to process management.

For example, a company can use FAT FINGER to create a digital checklist for quality control. This can help ensure that all steps in the production process are followed correctly, reducing the risk of defects and waste. Similarly, FAT FINGER can be used to create a digital workflow for shift handover, ensuring that all necessary information is communicated effectively and efficiently, reducing the risk of errors and delays.

Conclusion

Lean manufacturing has a significant impact on reducing production costs and enhancing quality. By eliminating waste, improving efficiency, and focusing on continuous improvement, it can help companies produce high-quality products efficiently and quickly. Digital workflow procedure builders like FAT FINGER can play a crucial role in facilitating lean manufacturing processes by providing a structured and standardized approach to process management.

If you’re interested in exploring how FAT FINGER can help your company implement lean manufacturing principles, sign up for a demo today.

Discover how Lean Manufacturing can significantly reduce your production costs and enhance quality. Learn more about the transformative impact of Lean Manufacturing by visiting FatFinger.io. Don’t wait, start optimizing your manufacturing process today!