Operational excellence is a critical component of any successful business. It involves optimizing processes and procedures to achieve the best possible results. One of the most effective ways to achieve Operational excellence is through the use of continuous improvement techniques. This is where FAT FINGER comes into play. FAT FINGER is a digital workflow procedure builder that empowers front-line teams to do their work correctly every time. It allows you to build checklists, workflows, and digital procedures that unlock Operational excellence.

Understanding Continuous Improvement Techniques

Continuous improvement techniques are strategies that businesses use to identify and implement small, incremental changes to their processes and procedures. These changes can lead to significant improvements in efficiency, productivity, and quality over time.

- Lean Manufacturing: This technique focuses on eliminating waste in all forms, including time, materials, and effort.

- Six Sigma: This method aims to reduce variability in processes, leading to a higher quality output.

- Total Quality Management (TQM): TQM involves a company-wide commitment to quality, with every employee working towards this goal.

How FAT FINGER Supports Continuous Improvement

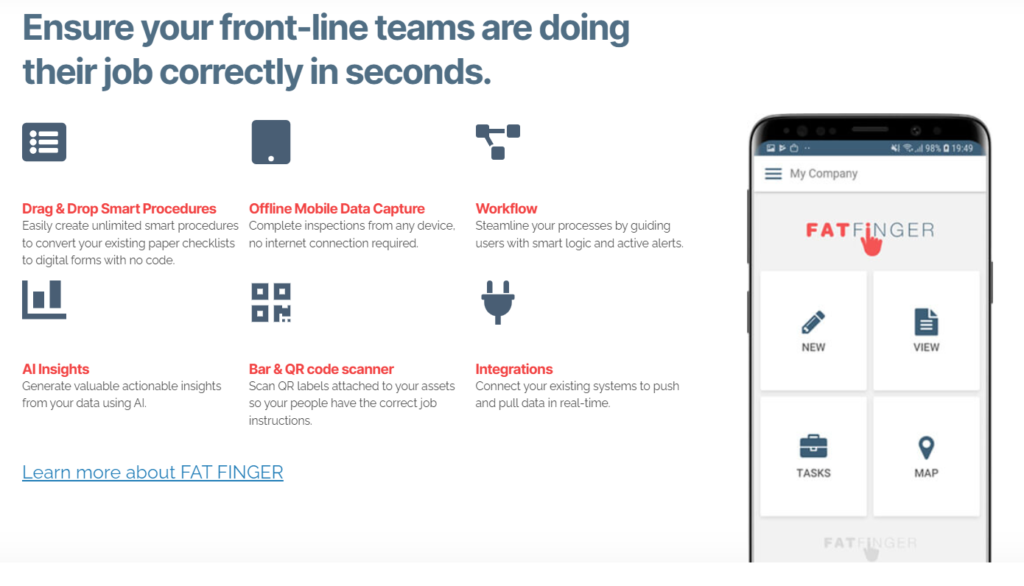

FAT FINGER supports continuous improvement in several ways. Its features include a drag & drop workflow builder, mobile & desktop workflows, dashboards, integrations, augmented reality, connect IoT devices, and artificial intelligence coaching. These features allow businesses to streamline their processes and ensure that every task is completed correctly and efficiently.

Case Study: Improving Safety with FAT FINGER

One area where FAT FINGER has proven particularly effective is in improving safety procedures. For example, the Take 5 Safety checklist allows teams to quickly and easily assess potential risks before starting work. This has led to a significant reduction in workplace accidents and injuries.

Case Study: Enhancing Quality Control with FAT FINGER

Another area where FAT FINGER excels is in quality control. The Quality Control checklist ensures that every product meets the company’s high standards before it leaves the factory. This has resulted in a significant decrease in product defects and returns.

Benefits of Using FAT FINGER

There are several benefits to using FAT FINGER for continuous improvement. These include:

- Improved Efficiency: FAT FINGER’s digital workflows and checklists eliminate the need for paper-based processes, leading to significant time savings.

- Increased Accuracy: The software’s built-in error checking and validation features ensure that tasks are completed correctly the first time.

- Better Decision Making: FAT FINGER’s dashboards provide real-time data and insights, allowing managers to make informed decisions.

Conclusion

In conclusion, achieving Operational excellence requires a commitment to continuous improvement. Techniques such as Lean Manufacturing, Six Sigma, and Total Quality Management can help businesses optimize their processes and procedures. However, implementing these techniques can be challenging without the right tools. That’s where FAT FINGER comes in. With its powerful features and user-friendly interface, FAT FINGER makes it easy to implement continuous improvement techniques and achieve Operational excellence.

Ready to achieve operational excellence? Implement continuous improvement techniques today! Visit FatFinger.io to learn more and start your journey towards improved efficiency and productivity.