In the ever-evolving world of manufacturing, leaders are constantly seeking innovative ways to improve efficiency, reduce waste, and increase productivity. One such innovation is the concept of Augmented Lean, a new management framework that combines the principles of Lean Manufacturing with the power of digital technology. This approach is revolutionizing the manufacturing industry, and tools like FAT FINGER, a digital workflow procedure builder, are at the forefront of this transformation.

Understanding Augmented Lean

Augmented Lean is a management framework that integrates Lean Manufacturing principles with advanced technologies such as Augmented Reality (AR), Internet of Things (IoT), and Artificial Intelligence (AI). This fusion allows manufacturing leaders to streamline processes, eliminate waste, and enhance productivity in ways that were previously unimaginable.

Processes that were once slow and cumbersome can now be made much faster and smoother, reducing the amount of time and resources needed to complete tasks. This can significantly improve the overall efficiency of the manufacturing operation.

In addition, by making processes more efficient, the fusion can reduce the amount of unnecessary work and therefore the amount of waste produced. This not only saves resources but also helps to make the manufacturing operation more environmentally friendly.

Furthermore, this fusion can enhance productivity. This is achieved by enabling manufacturing leaders to produce more goods in less time. It can also improve the quality of the goods produced, as more efficient processes can lead to fewer mistakes and therefore fewer defective products. Moreover, the fusion can also help to increase the flexibility of the manufacturing operation, allowing it to adapt more easily to changes in demand or market conditions.

Finally, all of these benefits not only improves the profitability and competitiveness of manufacturing companies but also has the potential to drive economic growth and technological progress.

The Role of FAT FINGER in Augmented Lean

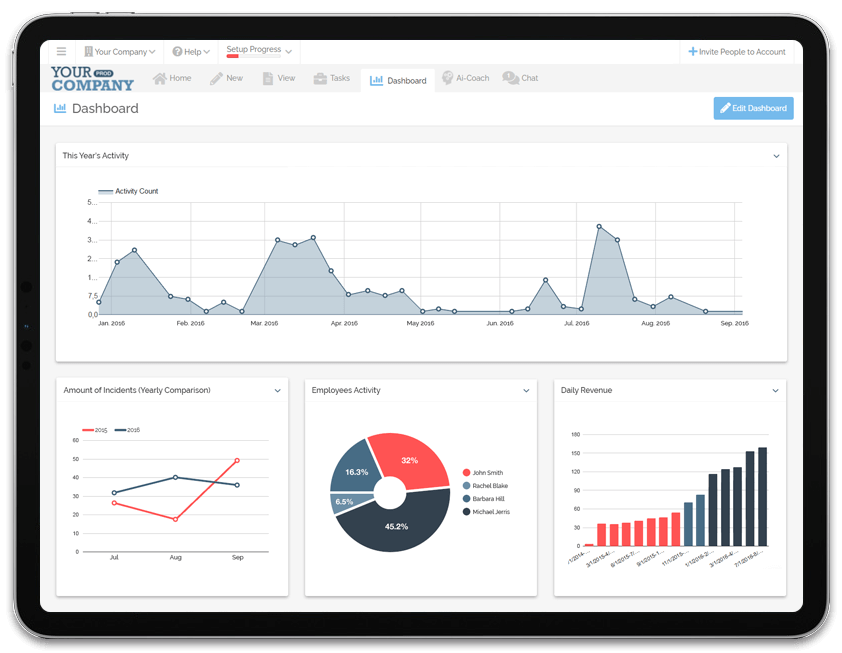

FAT FINGER is a powerful tool that empowers front-line teams to do their work correctly every time. It allows you to build checklists, workflows, and digital procedures that unlock operational excellence. With features like a drag & drop workflow builder, mobile & desktop workflows, dashboards, integrations, augmented reality, IoT device connectivity, and AI coaching, FAT FINGER is perfectly positioned to facilitate the implementation of Augmented Lean in your manufacturing processes.

Benefits of Augmented Lean

Implementing Augmented Lean in your manufacturing processes can yield significant benefits:

- Increased Efficiency: By digitizing and automating workflows, Augmented Lean reduces manual errors and increases process speed.

- Reduced Waste: Lean principles aim to eliminate waste, and digital tools like FAT FINGER make it easier to identify and eliminate inefficiencies.

- Improved Quality: Digital workflows ensure that every step is followed correctly, leading to consistent high-quality output.

- Enhanced Decision-Making: With real-time data and analytics, leaders can make informed decisions quickly.

Case Study: Augmented Lean in Action

A leading automotive manufacturer implemented Augmented Lean using FAT FINGER and saw remarkable results. They were able to reduce waste by 30%, increase productivity by 20%, and improve overall product quality. The real-time data provided by FAT FINGER also enabled them to make quicker, more informed decisions, leading to a more agile and responsive manufacturing process.

Conclusion

Augmented Lean is a powerful new management framework that combines the best of Lean Manufacturing principles with the power of digital technology. Tools like FAT FINGER are making it easier than ever for manufacturing leaders to implement this approach and reap the benefits of increased efficiency, reduced waste, improved quality, and enhanced decision-making. As the manufacturing industry continues to evolve, those who embrace Augmented Lean will be well-positioned to stay ahead of the curve.

Ready to take the first step towards implementing Augmented Lean in your manufacturing processes? Sign up for FAT FINGER or request a demo today to see how our digital workflow procedure builder can empower your front-line teams and unlock operational excellence.