As we navigate the fourth industrial revolution, the manufacturing industry is undergoing a significant digital transformation. This shift is driven by the need for increased efficiency, productivity, and competitiveness. One of the key players in this transformation is FAT FINGER, a digital workflow procedure builder that empowers front-line teams to do their work correctly every time. In this article, we will explore the future trends in manufacturing and how digital transformation is shaping the industry.

1. Internet of Things (IoT)

The Internet of Things (IoT) is revolutionizing the manufacturing industry by connecting devices and systems across the production line. This connectivity allows for real-time data collection and analysis, leading to improved efficiency and productivity. FAT FINGER’s ability to connect IoT devices makes it a valuable tool in this trend.

2. Artificial Intelligence (AI) and Machine Learning (ML)

AI and ML are becoming increasingly prevalent in manufacturing. These technologies can analyze vast amounts of data to identify patterns, predict outcomes, and make decisions. FAT FINGER’s Artificial Intelligence Coaching feature can guide teams through complex procedures, reducing errors and increasing efficiency.

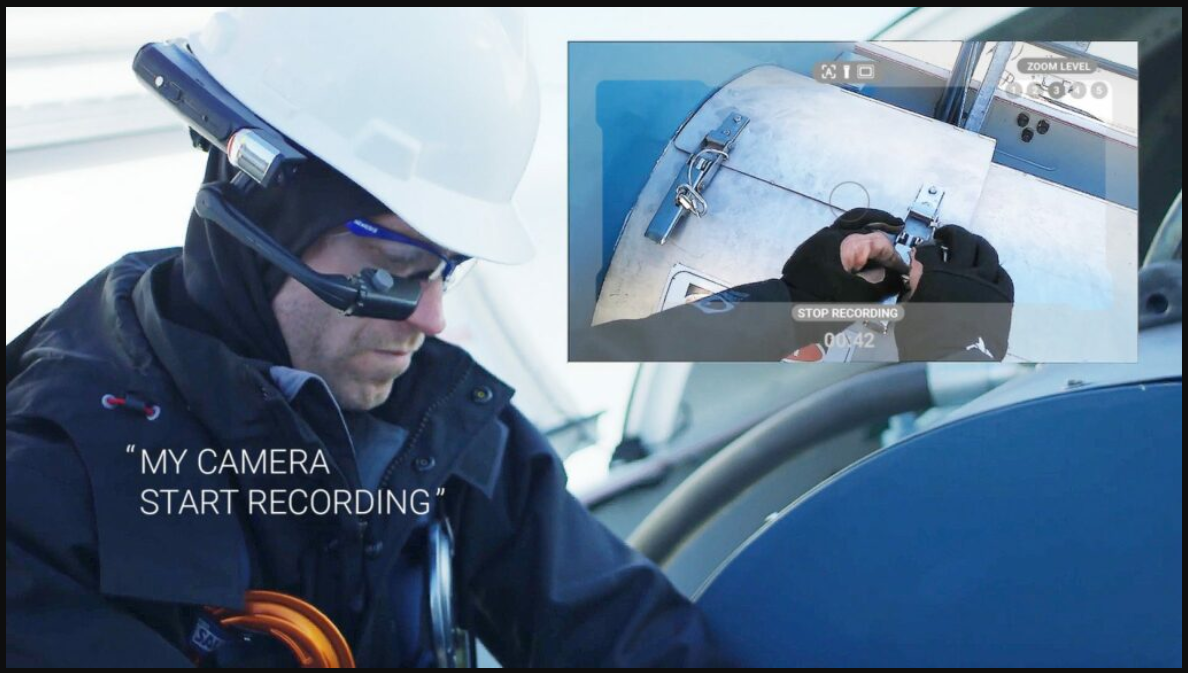

3. Augmented Reality (AR)

AR is another trend shaping the future of manufacturing. It can provide workers with real-time information and guidance, improving accuracy and speed. FAT FINGER’s Augmented Reality feature can enhance the effectiveness of workflows and procedures.

4. Mobile and Desktop Workflows

With the rise of remote work and the need for flexibility, mobile and desktop workflows are becoming essential. FAT FINGER allows teams to access workflows from any device, ensuring seamless operations regardless of location.

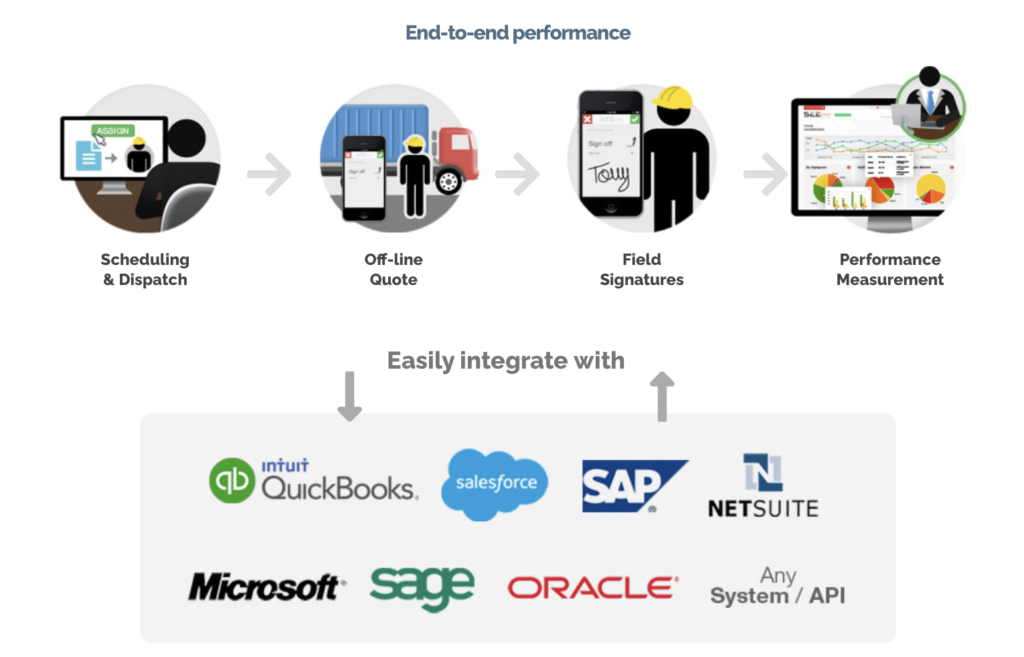

5. Integration

Integration of systems and software is crucial for streamlined operations. FAT FINGER’s integration capabilities allow it to work seamlessly with existing systems, enhancing efficiency and productivity.

6. Dashboards

Dashboards provide a visual representation of data, making it easier to understand and act upon. FAT FINGER’s dashboards offer clear insights into operations, aiding in decision-making and strategy formulation.

Conclusion

The future of manufacturing lies in digital transformation, with trends like IoT, AI, AR, mobile and desktop workflows, integration, and dashboards leading the way. FAT FINGER, with its comprehensive features, is well-positioned to aid manufacturers in this transformation, empowering teams to work more efficiently and effectively.

Ready to embrace the future of manufacturing? Sign up for FAT FINGER or request a demo today to see how it can revolutionize your operations.