Manufacturing is an industry that thrives on precision, efficiency, and consistency. In this context, governance and change management are critical to ensure that operations run smoothly and that any changes are implemented effectively. This is where FAT FINGER, a digital workflow procedure builder, comes into play. FAT FINGER empowers front-line teams to do their work correctly every time, unlocking operational excellence through its innovative features.

Enhancing Governance with FAT FINGER

Good governance in manufacturing involves setting clear procedures, ensuring compliance, and maintaining transparency. FAT FINGER supports these aspects in several ways:

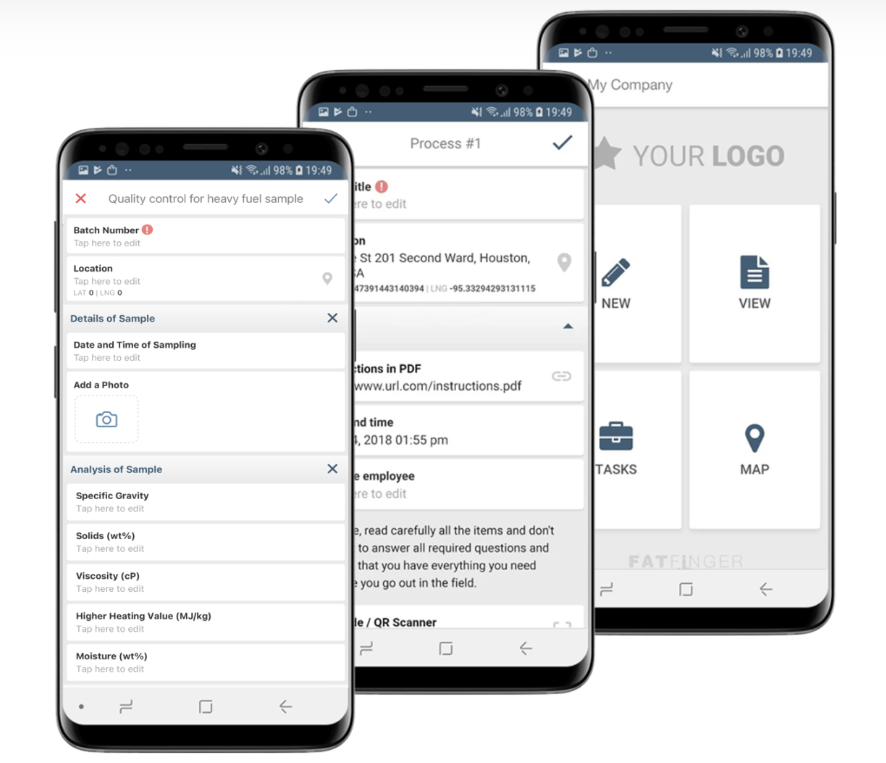

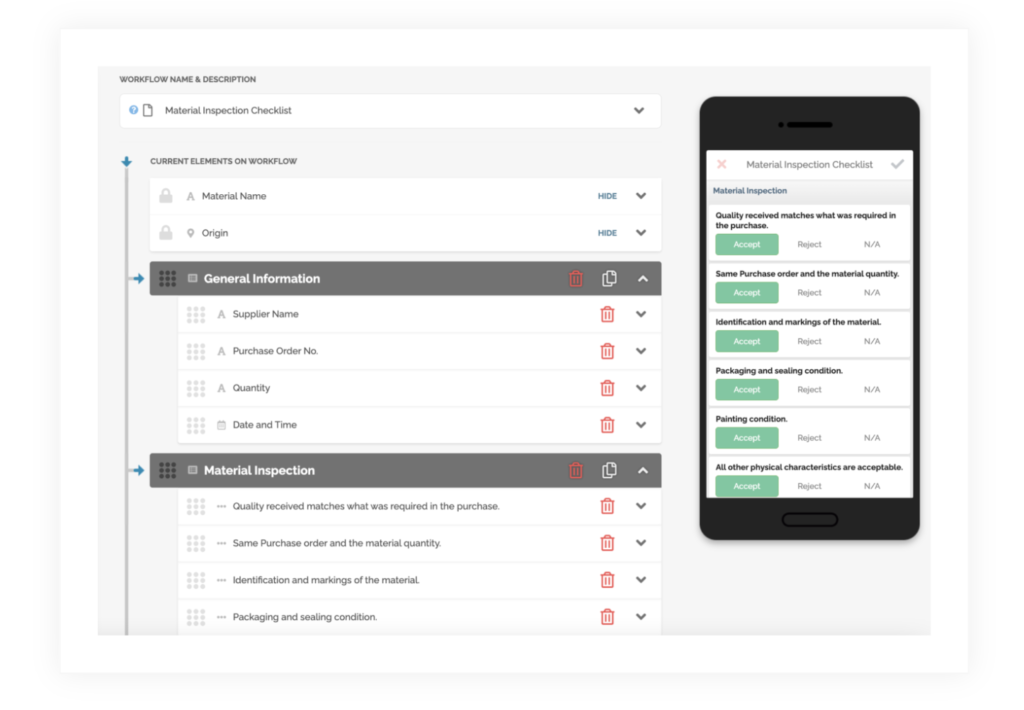

- Procedure Builder: FAT FINGER’s drag & drop workflow builder allows for the creation of clear, easy-to-follow procedures. This ensures that all team members understand their roles and responsibilities, enhancing accountability and governance.

- Compliance: With features like mobile and desktop workflows, dashboards, and integrations, FAT FINGER ensures that all procedures are followed to the letter, aiding in compliance with internal policies and external regulations.

- Transparency: FAT FINGER’s dashboards provide real-time visibility into operations, promoting transparency and enabling quick decision-making.

Facilitating Change Management with FAT FINGER

Change management is crucial in manufacturing to adapt to new technologies, market demands, and regulatory changes. FAT FINGER aids in this process through:

- Augmented Reality: This feature allows for virtual training and guidance, making it easier to introduce new procedures or equipment.

- Artificial Intelligence Coaching: FAT FINGER’s AI coaching provides personalized guidance to team members, helping them adapt to changes more effectively.

- Connect IoT Devices: By integrating with IoT devices, FAT FINGER enables real-time monitoring and control of manufacturing processes, facilitating seamless changes in operations.

Real-World Impact of FAT FINGER

FAT FINGER’s impact extends to various areas of safety, operations, and maintenance. For instance, it aids in risk assessment, incident reporting, quality control, shift handovers, preventive maintenance inspections, and predictive maintenance. By streamlining these processes, FAT FINGER not only enhances governance and change management but also boosts overall operational efficiency.

Below are examples of FAT FINGER’s solutions:

In risk assessment, FAT FINGER allows organizations to identify potential hazards or problems before they occur. With this tool, businesses can predict potential risks, determine their impact, and develop appropriate mitigation strategies. This proactive approach to risk management can significantly reduce the likelihood of incidents and accidents, thus enhancing overall safety.

Incident reporting is another area where FAT FINGER proves its worth. It provides a systematic and streamlined way to report incidents. This allows for detailed documentation and immediate action, leading to a more efficient resolution of the issue and preventing similar occurrences in the future.

In terms of quality control, FAT FINGER aids in monitoring and maintaining the standard of products or services. It can help identify inconsistencies or deviations from the established standard, allowing for timely corrections and ensuring high-quality output consistently.

Aside from these and other areas, FAT FINGER also enhances governance and change management. Its ability to document and track changes helps in maintaining transparency and accountability, which are crucial in effective management. Furthermore, by streamlining these processes, it boosts overall operational efficiency, leading to increased productivity and profitability. Thus, FAT FINGER’s impact extends far beyond just maintenance and operations; it is a valuable tool for enhancing business performance as a whole.

Conclusion

In conclusion, FAT FINGER is a powerful tool that supports governance and change management in manufacturing. Its innovative features enable clear procedures, ensure compliance, promote transparency, facilitate training, and integrate with IoT devices. By doing so, it empowers front-line teams to do their work correctly every time, unlocking operational excellence. Whether you’re looking to enhance governance, manage change more effectively, or simply boost operational efficiency, FAT FINGER has you covered.

Ready to experience the benefits of FAT FINGER for yourself? Sign up today or request a demo to see how it can transform your manufacturing operations.