In the manufacturing industry, compliance and audits are critical aspects that ensure the quality and safety of products. However, these processes can be complex, time-consuming, and prone to human error. This is where FAT FINGER comes in. FAT FINGER is a digital workflow procedure builder that empowers front-line teams to do their work correctly every time. It allows you to build checklists, workflows, and digital procedures that unlock operational excellence.

Challenges in Compliance & Audits

Manufacturing companies face several challenges in compliance and audits.

Manufacturing companies often face a variety of challenges when it comes to compliance and audits. One of the main challenges is the complexity and constant evolution of laws and regulations. These laws are often complex and can change frequently, making it difficult for companies to stay up to date.

Another major challenge is the cost of compliance. This includes the cost of hiring compliance officers, implementing compliance programs, and the potential fines and penalties for non-compliance. In some cases, the cost of compliance can significantly impact a company’s bottom line.

In addition, many manufacturing companies operate in multiple jurisdictions, each with its own unique set of laws and regulations. This adds another layer of complexity to the compliance process.

Audits also present their own set of challenges. These can be time-consuming and disruptive to normal business operations. They also require a significant amount of preparation, including gathering and organizing documentation, and ensuring that all processes and procedures are compliant.

Furthermore, there is the challenge of maintaining a positive relationship with regulators. This requires open communication, transparency, and a proactive approach to compliance.

Lastly, in today’s digital age, companies also have to deal with issues related to data privacy and security. They have to ensure that they are compliant with various data protection regulations, and that they have robust systems in place to protect sensitive data.

Despite these challenges, compliance and audits are critical for manufacturing companies. They help to ensure that companies operate within the law, protect their reputation, and avoid costly fines and penalties. Therefore, companies must invest in effective compliance programs and be prepared for audits. Traditional methods of managing these processes often lead to inefficiencies and errors.

How FAT FINGER Streamlines Compliance & Audits

FAT FINGER addresses these challenges by providing a platform that simplifies and streamlines compliance and audit processes. Here’s how:

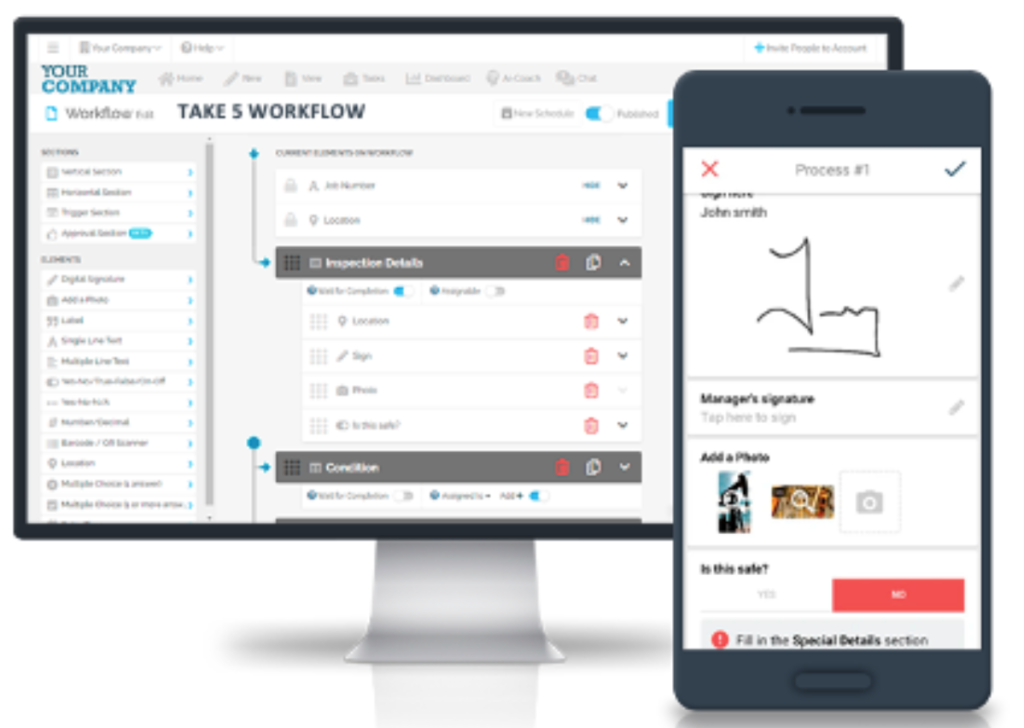

- Drag & Drop Workflow Builder: This feature allows you to easily create and modify workflows, making it easier to adapt to changes in compliance requirements.

- Mobile & Desktop Workflows: FAT FINGER’s platform is accessible on both mobile and desktop devices, enabling teams to access and update compliance data from anywhere, at any time.

- Dashboards: With FAT FINGER’s dashboards, you can monitor compliance and audit processes in real-time, making it easier to identify and address issues promptly.

- Integrations: FAT FINGER can be integrated with other systems, allowing for seamless data flow and reducing the risk of data inconsistencies.

- Augmented Reality, Connect IoT Devices, Artificial Intelligence Coaching: These advanced features further enhance the efficiency and accuracy of compliance and audit processes.

Case Study: FAT FINGER in Action

A leading manufacturing company implemented FAT FINGER to streamline its compliance and audit processes. The company was able to reduce the time spent on compliance tasks by 50%, while also significantly improving the accuracy of its data. This case study demonstrates the potential of FAT FINGER to transform compliance and audit processes in the manufacturing industry.

Conclusion

Compliance and audits are crucial in the manufacturing industry, but they can also be complex and time-consuming. FAT FINGER provides a solution that simplifies these processes, reduces errors, and saves time. By leveraging features like the drag & drop workflow builder, mobile & desktop workflows, dashboards, integrations, and advanced technologies like augmented reality and artificial intelligence, FAT FINGER empowers manufacturing teams to achieve operational excellence.

If you’re looking to streamline your compliance and audit processes, consider implementing FAT FINGER in your operations. Sign up for FAT FINGER or request a demo today to see how it can transform your manufacturing operations.