As industries evolve, the need for efficient and effective shutdown operations becomes increasingly critical. One of the key players in this digital transformation is FAT FINGER, a digital workflow procedure builder that empowers front-line teams to do their work correctly every time. This article explores strategies for seamlessly integrating connected work tools in shutdown operations, with a focus on the capabilities of FAT FINGER.

Understanding the Importance of Connected Work Tools in Shutdown Operations

Shutdown operations, also known as turnarounds, are planned, periodic work stoppages necessary for maintenance, inspection, and testing. The integration of connected work tools in these operations can significantly enhance efficiency, reduce downtime, and improve safety.

Key Strategies for Seamless Integration

Integrating connected work tools in shutdown operations requires a strategic approach. Here are some key strategies:

- Choose the right tools: FAT FINGER, for instance, offers a range of solutions from safety to operations and maintenance, including a specific Shutdown/Turnaround form.

- Ensure compatibility: The chosen tools should be compatible with existing systems and processes.

- Train your team: Adequate training ensures that all team members can effectively use the tools.

- Monitor and adjust: Regular monitoring allows for necessary adjustments to be made for optimal performance.

Case Study: FAT FINGER in Action

A case study that illustrates the effectiveness of FAT FINGER is its use in a major manufacturing company. The company was facing challenges in managing its shutdown operations, leading to extended downtime and increased costs. After implementing FAT FINGER, the company was able to streamline its processes, reduce downtime, and improve safety. The company particularly benefited from the Preventive Maintenance Inspection and Shutdown/Turnaround form features of FAT FINGER.

Benefits of Using FAT FINGER in Shutdown Operations

Using FAT FINGER in shutdown operations offers several benefits:

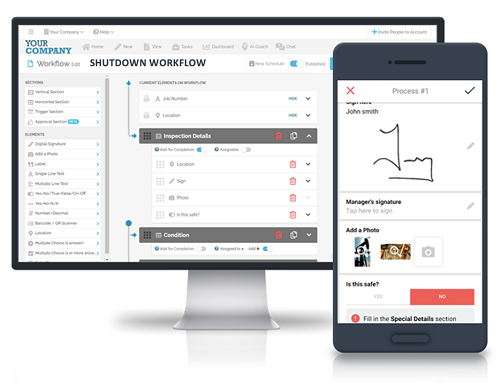

- Efficiency: FAT FINGER’s drag and drop workflow builder allows for easy creation and modification of workflows.

- Flexibility: The software can be used on both mobile and desktop, allowing for on-the-go access.

- Insights: The dashboards provide valuable insights into operations, helping to identify areas for improvement.

- Integration: FAT FINGER can be integrated with IoT devices and uses artificial intelligence for coaching.

Conclusion

Seamless integration of connected work tools in shutdown operations is crucial for operational excellence. Strategies such as choosing the right tools, ensuring compatibility, training the team, and monitoring performance can help achieve this integration. FAT FINGER, with its range of features and solutions, is a valuable tool for this purpose. By leveraging FAT FINGER, companies can streamline their shutdown operations, reduce downtime, and improve safety.

Ready to transform your shutdown operations? Sign up for FAT FINGER or request a demo today.