When it comes to workplace safety, it is essential for employees to be able to recognize when a situation has become dangerous and know how to stop work.

The STOP safety program is a procedure that employees can follow to stop work safely in the event of imminent danger. The STOP program’s findings are recorded in a card called the STOP card.

Table of Contents:

I. What is the STOP Program in HSE?

II. When Should you Require STOP Work?

III. How does the STOP program work?

IV. What are the benefits of the STOP Card Safety Form?

V. Advancing STOP Card Safety Form with FAT FINGER

What is the STOP Program in HSE?

The STOP program is a safety initiative in the HSE that has shown to be very effective in preventing injuries in the workplace. “STOP” stands for Safety Training Observation Programme. The STOP program is based on the behavior-based safety principle, which focuses on changing the unsafe behaviors that lead to accidents.

The STOP program involves four main elements: training, observation, corrections, and STOP work authority.

- The training element ensures that all employees are adequately educated on the hazards in their work environment and how to work around them safely.

- The observation element allows for trained STOP observers to identify unsafe behaviors as they are happening and take corrective action before an accident can occur.

- The corrections element gives STOP observers the authority to stop work if they see unsafe behavior that could result in an accident.

- The STOP work authority gives STOP observers the authority to shut down a work process if they believe it is too dangerous to continue.

The STOP program has been proven effective in reducing accidents and injuries that happen in the workplace. If you are looking for a way to improve safety in your workplace, the STOP program is a great place to start.

When Should you Require STOP Work?

The STOP Work program is a policy that should be implemented for behaviors or situations posing a risk to people, equipment, or the environment.

The STOP program is not all-inclusive but covers the majority of safety hazards. This includes but is not limited to

• Events that prompt the use of an alarm.

• An alteration to the scope of work or plan.

• A change in conditions.

• Lack of knowledge, understanding, or information.

• Equipment being used improperly.

• An emergency situation.

• Unsafe conditions.

• A near miss incident.

If in doubt, STOP Work Authority should be initiated. STOP Work Authority can be initiated by any employee, manager, engineer, safety professional, etc. STOP Work Authority is a voluntary program and is not disciplinary.

How Does the STOP Program Work?

The STOP program is a proactive approach to safety that encourages employees to be aware of their surroundings and to identify potential hazards. The STOP program is based on the premise that employees are more likely to identify potential hazards if they are actively looking for them. The STOP program has four steps:

- Identification: Employees identify potential hazards in their work area.

- Assessment: Employees assess the risks associated with the identified hazard.

- Control: Employees implement controls to eliminate or reduce the risks associated with the hazard.

- Review: Employees review the hazard and control measures periodically to ensure they remain effective.

The STOP program is an effective way to improve safety in the workplace by encouraging employees to be aware of their surroundings and to identify potential hazards. The STOP program can be used in any workplace, regardless of the type of business or industry.

All these observations made during the STOP program are recorded in a card called – STOP CARD.

What are the benefits of the STOP Card Safety Form?

The STOP Card Safety form is a vital component of the STOP program, which provides valuable information about this safety program to various industrial sectors and their workers. Moreover, STOP Card Safety Form aims to:

- Identify potential safety concerns.

- Identify trends and problems that may exist in the workplace.

- Prevent injuries and illnesses in the workplace.

- Investigate potential hazards, and develop corrective action plans.

By sharing the behavior observation from the STOP safety card with everyone, all can work together safely and more effectively.

Advancing STOP Card Safety Form with FAT FINGER

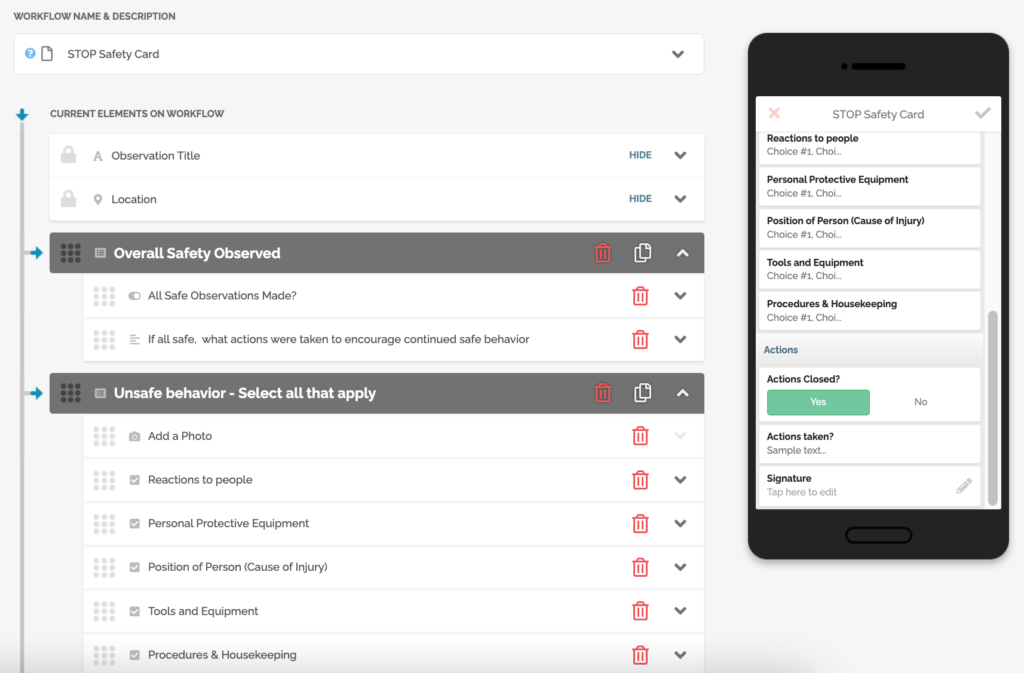

STOP Card Safety forms are an essential tool in assessing and preventing risks in the workplace. However, paper-based STOP Card Safety forms can be lost or damaged, making it challenging to track safety information over time. FAT FINGER is a digital platform that helps to streamline the STOP Card Safety form process.

With FAT FINGER, STOP Card Safety forms can be efficiently completed and stored electronically, making it easier to track and manage safety information.

FAT FINGER enables industries to quickly and easily conduct comprehensive STOP safety inspections, identify potential hazards, and track corrective actions. Whether it is for oil and gas, or any manufacturing companies looking to improve their STOP safety programs, FAT FINGER is the ideal solution.

With this pre-made template, you can start capturing your STOP safety data right away, or modify the app to meet your requirements using our Workflow builder.

For a tutorial on how FAT FINGER can help your safety see this safety inspection video.

Are you concerned that something may hinder your STOP safety program at work?

With FAT FINGER, you can be sure that your STOP safety program is always up-to-date and compliant with regulations.

Various users have confirmed that using the FAT FINGER platform can resolve workplace hazards 83% faster, 85% more people are held accountable for their actions, and 60% of workplaces have been made safer.

Don’t waste another day not knowing what needs to be done to improve safety in your workplace – download FAT FINGER today!

About FAT FINGER

Ensure front-line teams do their work correctly every time. Drag & drop digital procedures that unlock operational excellence.

In seconds anyone can build and deploy enterprise-grade mobile applications using an easy drag-and-drop no-code builder.

FAT FINGER uses machine learning to coach app users in real-time to make safer and improved decisions.

Try building your digital procedure on FAT FINGER for free @ www.fatfinger.io