Lock out/Tag out is an important safety procedure that helps protect employees from injury while working on equipment.

According to preliminary OSHA Information System data, lock out/tag out was sixth on the OSHA Top 10 list of most frequently cited standards in FY 2021, with around 1,670 total violations.

This means that it is crucial for companies to have a consistent lock out/tag out procedure checklist in place and to train their employees on how to use it properly.

This article will provide an overview of the lock out/tag out procedure and discuss how the lock out tag out procedure checklists checklist ensures safety in the workplace.

Table of Contents

1. What is Lock Out Tag Out?

2.Types of LOTO devices

3. 5 Steps of LOTO Procedure

4. Components of Lock Out Tag Out Procedure Checklist

5. Reliable Tool for Lock Out Tag Out Procedure

What is Lock Out Tag Out?

Lock out tag out, or LOTO, is a safety procedure to prevent machinery and equipment from accidental or unauthorized operation.

The term lock out tag out refers to the process of locking and tagging out all potential energy sources before work is begun on a machine or piece of equipment. This includes turning off the power, removing keys, and attaching locks and tags to all controls.

While LOTO procedures may seem like a hassle, they are actually extremely important for preventing accidents and ensuring the safety of workers. There are several key benefits of lock out tag out:

- LOTO prevents accidental start-up of machinery. This is perhaps the most essential benefit of LOTO, as it can prevent serious injuries or even fatalities.

- LOTO helps to ensure that only trained personnel work on machinery. By ensuring that only authorized personnel have access to the lock and key, LOTO helps to reduce the risk of unauthorized repairs or modifications being made.

- LOTO minimizes the risk of equipment damage. By properly shutting down and isolating machinery, LOTO can help to prevent damage from occurring during maintenance or repair work.

Overall, lock out tag out is an essential safety procedure that provides numerous benefits. When used correctly, it can help to prevent accidents, injuries, and equipment damage.

Types of LOTO Devices

There is a variety of lock out tag out (LOTO) devices available on the market, each designed for specific applications. Some common types of LOTO devices include padlocks, hasps, circuit breaker locks, and valve lockouts.

Padlocks

Padlocks are the most basic type of LOTO device and can be used to secure various equipment, from electrical panels to machinery. Padlocks are available in a variety of materials, including brass, steel, and aluminum. They can also be customized with engraved names or logos. When choosing a padlock for LOTO purposes, it is essential to select a durable and corrosion-resistant lock. Padlocks should also be equipped with key-retaining features to prevent accidental lockouts.

Hasps

Hasps are another common type of LOTO device and are often used in combination with padlocks. Hasps are available in both fixed and adjustable varieties. Fixed hasps are designed to be used with a specific size of the lock, while adjustable hasps can be adjusted to fit various lock sizes. Hasps are typically made from metal, but plastic and vinyl have also been used. When selecting a hasp, it is crucial to consider the type of lock that will be used, the environment in which the hasp will be used, and the strength and durability of the hasp.

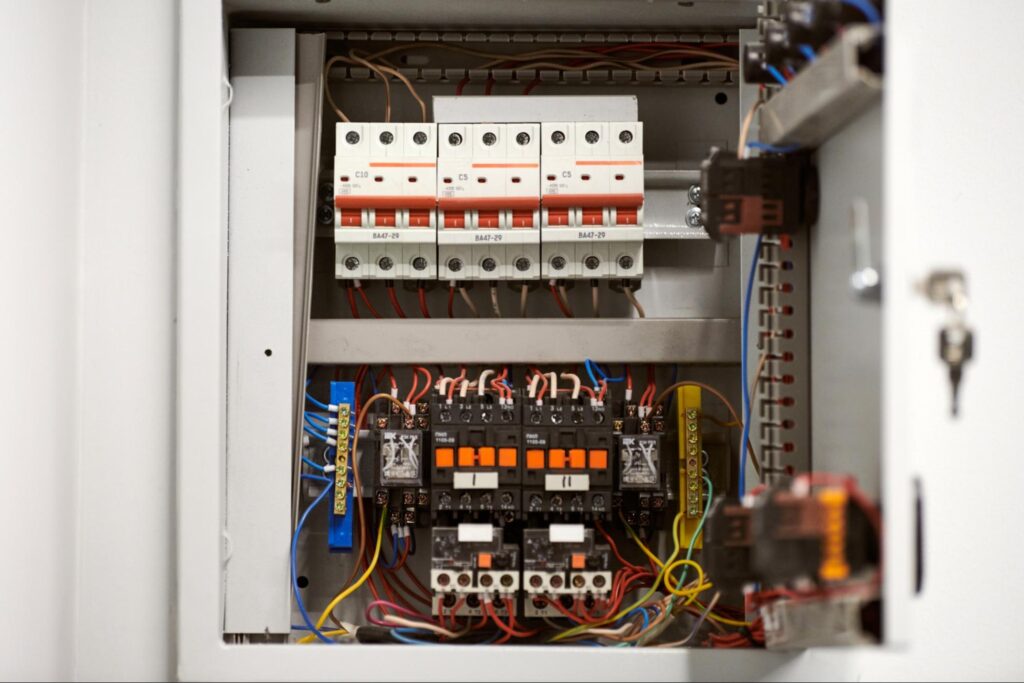

Circuit breaker

Circuit breaker locks are an essential safety device in any industrial or commercial setting. They are designed to lock out power sources, preventing employees from being electrocuted or injured while working on equipment. When selecting circuit breaker locks, it is vital to choose a model that is compatible with the specific make and model of the circuit breaker in your facility.

Valve lockouts

Valve lockouts are one type of lock out tag out device. Valve lockouts are used to prevent unauthorized personnel from opening or tampering with valves. Valve lockouts are placed over the valve handle, lever, or knob and secured with a lock. The lock prevents the valve from being turned on or off. Only authorized personnel with the key to the lock can remove the lock and turn the valve.

The type of LOTO device used will depend on the specific circumstances and needs of the workplace. For example, if multiple workers will be working on the same piece of equipment simultaneously, then a hasp would likely be used so that each worker can apply their own lock. In contrast, if only one worker will be working on the equipment and there is no need for locks to be removed and reapplied, then a lock might be sufficient.

When selecting a LOTO device, choosing one appropriate for the specific application is essential. Using the wrong type of device can create a safety hazard.

5 Steps of LOTO Procedure

Most people are familiar with the term “lock out tag out” (LOTO), but few know the steps involved in carrying out a LOTO procedure. As a safety engineer or manager, it’s essential to be familiar with the LOTO process to ensure it’s being carried out correctly in your workplace. Here’s a quick overview of the steps involved in a typical LOTO procedure:

1. Isolation: The first step is to isolate the energy source from the system or machine. This typically involves disconnecting electrical power, turning off gas or water lines, or removing batteries.

2. Lockout: Once the energy source has been isolated, lockout devices are used to prevent it from being reconnected. Lockout devices should be affixed by a qualified person and should only be removed by that same person.

3. Tag out: A tag out device is then attached to the lock to provide a visual warning that the system is not to be energized. The tag should contain information such as the name of the qualified person who applied the lock, the date, and other relevant safety information.

4. Testing: Once all locks and tags are in place, the system should be tested to ensure it cannot be energized. This step is often overlooked, but it’s essential to confirm that the system is truly isolated before proceeding.

5. Maintenance/Repair: Once the system has been confirmed to be isolated, maintenance or repair work can begin. When work is completed, all locks and tags should be removed, and the system should be tested again before being brought back online.

By following these steps, you can help ensure that your workplace is safe and that any maintenance or repair work is carried out correctly. A lock out tag out procedure checklist can be a helpful tool in ensuring that all steps are carried out correctly.

Components of Lock Out Tag Out Procedure Checklist

A lock out tag out procedure checklist is a tool that can be used to ensure that all steps in the lock out tag out procedure are carried out correctly. The procedure typically involves creating a checklist that outlines all the steps that need to be taken to lock out and tag the equipment safely.

- General Information: This includes the equipment’s name and the purpose of LOTO activity. This section also includes the employees involved, date, and time.

- Type of Hazardous Energy Involved: The first step in a LOTO procedure is to identify all of the energy sources that could potentially be hazardous. This comprised of electrical, hydraulic, pneumatic, mechanical, and chemical energy sources.

- Type of LOTO device: This includes padlocks, hasps, circuit breaker locks, and valve lockouts or combinations of both.

- Procedures to lock out the equipment safely: The checklist should include all the steps necessary to lock out the equipment, as well as any other safety precautions that need to be taken. Examples include:

-Inform any affected employees or outside contractors that we will be locking out the equipment.

-Disengage all hazardous energy sources.

-Apply the appropriate LOTO device.

-Attempt to restart equipment through normal means and return the switch to the OFF position.

5. Procedures to re-energize the equipment

In order to restart the affected LOTO machine, you’ll need to follow these steps listed in the checklist. Additionally, be sure to consider all other safety precautions before taking any further action. Some of the standard procedures include:

-Inspect the work zone to ensure it is clear of equipment, workers, tools, and test equipment.

-Warn affected workers to stay clear of the area.

-Remove all locks and tags from energy control points.

-Verify the area is clear of personnel.

-Reenergize the equipment.

-Inform affected employees that LOTO is completed.

A LOTO procedure checklist helps ensure that all the necessary steps are taken to safely lock out, and tag equipment before maintenance or repair work is performed. By following this information in your checklist, you can be sure that employees are safe and that equipment is appropriately protected.

Reliable Tool for Lock Out Tag Out Procedure

Machinists, machine operators, and laborers are among the 3 million people who work on equipment and face the highest hazard. Every year, compliance with the lock out/tag out standard prevents an estimated 120 deaths and 50,000 injuries in the workplace. For every day of recuperation lost as a result of exposure to hazardous energy at work, employees suffer an average of 24 days off from work which contributes to lower productivity.

FAT FINGER is a powerful mobile tool that makes it easier for workers to follow LOTO procedures. It streamlines the LOTO process by providing checklist templates that can be easily customized and completed onsite.

With FAT FINGER digital lock out tag out procedure checklist, workers can use mobile devices to access LOTO checklists and record the steps they take to mitigate hazards. FAT FINGER then automatically submits reports on the steps taken so far, and stores record securely in the cloud. This makes it easy for safety managers to track progress and ensure that all workers are following proper procedures.

Do you need a better way to communicate your Lockout/Tagout (LOTO) strategies?

FAT FINGER was created by like-minded individuals who understand the importance of safety and want to make it easier for everyone to comply with LOTO procedures.

Making sure your workplace is safe shouldn’t be a hassle, so we’ve made our app easy to use. With FAT FINGER, everyone can easily create workflows with drag-and-drop no-code builder. All your up-to-date work instructions and training content are available across any device as employees perform the work.

FAT FINGER helps you take photos and record the actions taken to mitigate them during LOTO. You can even submit reports automatically so that everyone is always up-to-date on the latest LOTO procedures.

This way, you can be confident that everything is done correctly every time. Not to worry, our secure Cloud storage will keep all your data safe in case any issues should arise.

Don’t waste another day not knowing what needs to be done to improve LOTO in your workplace – download FAT FINGER today!

About FAT FINGER

Ensure front-line teams do their work correctly every time. Drag & drop digital procedures that unlock operational excellence.

In seconds anyone can build and deploy enterprise-grade mobile applications using an easy drag-and-drop no-code builder.

FAT FINGER uses machine learning to coach app users in real-time to make safer and improved decisions.

Try building your digital procedure on FAT FINGER for free @ www.fatfinger.io