Quality Control (QC) and Quality Assurance (QA) are two concepts that often play a crucial role in achieving quality in industrial processes. On the other hand, Quality Assurance is a

broader and more comprehensive approach to quality management. Let’s delve into the nuances of quality control vs quality assurance, to understand how they contribute to the overall quality management of a business.

Quality Control vs Quality Assurance

The table below compares QC and QA across different comparison points, such as their objectives, focus, timing, and focus on continuous improvement, among other aspects.

| Aspect | Quality Control (QC) | Quality Assurance (QA) |

| Definition | Focuses on identifying and correcting defects in the final product. | Aims to prevent defects by establishing robust quality management systems. |

| Objective | Ensures immediate quality of products or services. | Takes a proactive approach to maintaining consistent quality over time. |

| Nature | Reactive. Addresses issues after they occur. | Proactive. Aims to prevent issues before they impact the final product. |

| Focus | Product-oriented. Concerned with the final output. | Process-oriented. Concerned with the entire production process. |

| Components | – Inspection and testing. | – Standards and guidelines. – Audits. – Continuous improvement. |

| Role in Process | Identifies and corrects deviations from quality standards during or after production. | Establishes frameworks and processes to prevent defects from occurring. |

| Aspect | Quality Control (QC) | Quality Assurance (QA) |

| Timing of Activities | Activities occur during or after the production process. | Activities start at the design phase and continue throughout the production process. |

| Feedback Loop | Provides data and feedback for QA processes. | Utilizes data and insights from QC for continuous improvement. |

| Measurement of Success | Reduced defects, immediate quality assurance. | Consistent quality over time, prevention of defects, and customer satisfaction. |

| Implementation Challenges | – Cost of implementation. – Resistance to change. | – Requires a cultural shift. – Implementation complexity. |

| Technology Integration | Relies on testing and inspection methods. | Embraces technology like IoT, data analytics, and AI for real-time monitoring. |

| Industries | Common in manufacturing. | Applicable across various industries, including service and software development. |

| Continuous Improvement | May lead to continuous improvement but not inherently built for it. | Inherently focuses on continuous improvement through ongoing processes. |

Pros and Cons of Quality Control

Pros:

- Immediate Issue Identification: Quality Control excels in identifying defects and deviations from quality standards during or after the production process. This enables swift corrective actions, preventing the distribution of subpar products.

- Cost Efficiency: Implementing QC measures can contribute to cost efficiency by identifying and rectifying issues early, reducing the need for expensive recalls or rework.

- Tangible Metrics: QC provides tangible metrics for evaluating the quality of products, making it easier to measure success and identify areas for improvement.

- Industry Compliance: QC is often essential for industries with strict regulatory standards, ensuring products meet compliance requirements.

Cons:

- Reactive Approach: QC is inherently reactive, addressing issues after they occur. This can result in the distribution of defective products before corrective actions are taken.

- Limited Preventive Measures: While QC identifies issues, it doesn’t inherently prevent them. It focuses on correction rather than proactive defect prevention.

- Cost of Implementation: Implementing robust QC processes can be costly, involving expenses related to testing equipment, trained personnel, and inspection procedures.

- Potential for Wastage: If defects are identified late in the production process, there may be significant wastage of materials and resources.

Pros and Cons of Quality Assurance

Pros:

- Proactive Defect Prevention: Quality Assurance takes a proactive approach, aiming to prevent defects by establishing comprehensive quality management systems. This prevents issues from arising in the first place.

- Consistent Quality: QA focuses on maintaining consistent quality throughout the entire production process, contributing to customer satisfaction and brand reputation.

- Long-Term Cost Savings: While the initial implementation of QA may require investment, the long-term benefits include cost savings through the prevention of defects and the need for extensive rework.

- Continuous Improvement: QA inherently incorporates a culture of continuous improvement, fostering an environment where processes are regularly evaluated and refined.

Cons

- Cultural Shift: Implementing QA often requires a cultural shift within an organization. It may face resistance from employees accustomed to a more reactive approach.

- Implementation Complexity: Establishing robust QA processes can be complex and time-consuming. It involves creating and enforcing standards, conducting audits, and implementing ongoing improvement measures.

- Data Overload: In some cases, the extensive data collection and analysis involved in QA processes can lead to information overload, making it challenging to extract meaningful insights.

- Not Immediate Issue Resolution: QA focuses on long-term prevention, so immediate issue resolution may not be as emphasized as in QC.

Why Use FAT FINGER for QC and QA

Although QC and QA are different as is evident above, many organizations find success in integrating elements of both to create a comprehensive quality management strategy.

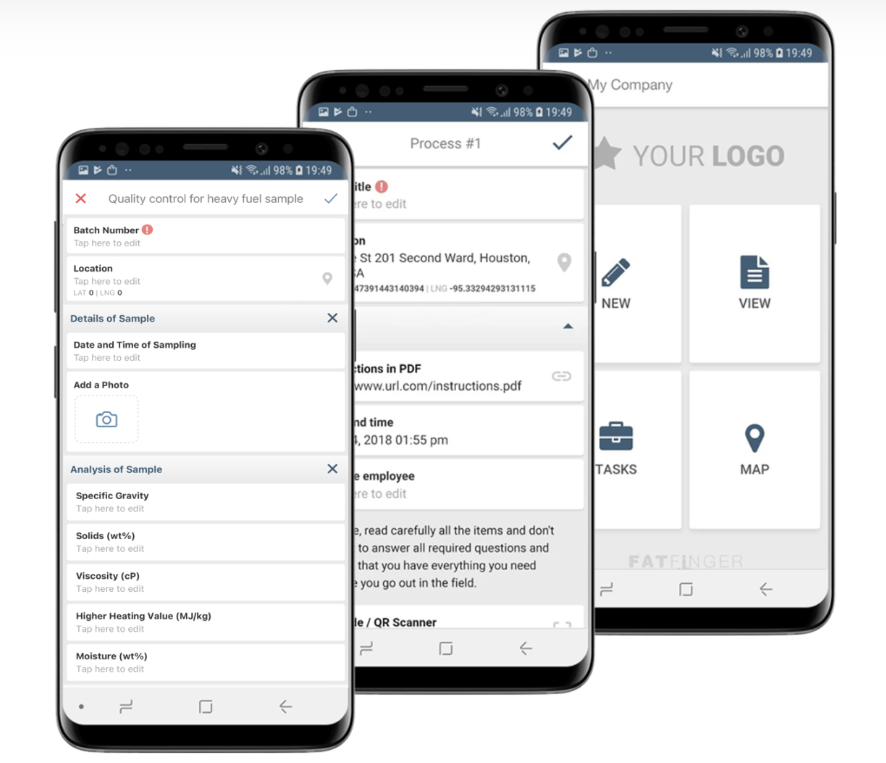

As technology evolves, integrating digital solutions like FAT FINGER can play a pivotal role in enhancing overall quality management systems.

Benefits of Using FAT FINGER

Using FAT FINGER for quality control and quality assurance can offer numerous benefits, including improved efficiency, data accuracy, and transparency.

- Efficient Data Collection: Efficient data collection in different stages of production is crucial especially for quality control processes that rely on accurate and timely information.

- Real-time Monitoring: Real-time monitoring of processes ensures prompt corrective actions.

- Customizable Forms: FAT FINGER’s drag and drop workflow builder makes it easy to create inspection checklists tailored to specific quality control or quality assurance requirements.

- Reduced Human Error: By digitizing data collection, FAT FINGER helps minimize the risk of human error associated with manual recording and transcription.

Say goodbye to rigid, manual inspections processes. Sign up for FAT FINGER and create digital procedures to speed up issue identification, experience proactive quality management, and emphasize prevention and continuous improvement.