Material inspection in construction is an intricate process beyond merely validating materials; it’s a safeguard ensuring a construction project’s longevity, safety, and success.

This detailed exploration will unravel the layers of material inspection in the construction industry, and highlight the benefits of digitizing this process with FAT FINGER.

What Does Material Inspection in Construction Involve?

In construction, material inspection is a systematic evaluation that extends from the molecular structure of materials to their macro-level applications. It involves scrutinizing materials to confirm compliance with stringent quality standards and regulatory guidelines to ensure a construction project’s structural soundness and safety.

Ensuring Quality Control

Quality control in material inspection is not a one-time checkbox; it’s a continuous, vigilant process. It involves exhaustive testing, in-depth examination, and rigorous verification of materials at every stage of construction. The objective is to identify any defects, irregularities, or deviations from standards that could compromise the quality of the final construction project.

Compliance with Regulations

Material inspection acts as a conduit between construction practices and regulatory requirements. It ensures that every material used aligns with industry standards and local regulations. Beyond avoiding legal repercussions, this compliance fosters a culture of responsibility, contributing to the overall integrity and reputation of the construction industry.

Enhancing Site Safety

The ultimate objective of material inspection is to create a secure working environment. By meticulously verifying that all materials meet safety standards, material inspection significantly reduces the risk of accidents, injuries, and structural failures on the construction site. It is the proactive approach to ensuring the well-being of everyone involved.

Key Materials Inspected

A complete inspection in construction involves checking different materials and safety equipment.

Inspecting Structural Materials

The backbone of any construction project lies in its structural materials. Material inspection in this category involves microscopic examination of concrete, steel, and wood materials. It ensures that these materials possess the requisite strength, durability, and resilience to support the intended structure over its lifespan.

Finishing Materials

While structural integrity is paramount, the finishing materials contribute to the project’s aesthetics, functionality, and longevity. Material inspection involves assessing materials like paint, tiles, coatings, and other finishing touches. The goal is to guarantee visual appeal and resistance to wear, weather, and environmental factors.

Safety Equipment

In addition to the primary construction materials, inspection extends to safety equipment. Harnesses, guardrails, and other safety components are scrutinized to ensure they meet safety standards. This aspect of inspection is critical in providing essential protection for workers on-site.

3 Steps to Conduct Material Inspection In Construction

Step 1 – Pre-Inspection Planning

Before a single brick is laid, you should meticulously plan a robust pre-inspection plan . This planning phase involves a multidimensional approach, identifying critical materials, setting inspection frequencies based on project milestones, and establishing detailed documentation procedures.

The goal is to create a roadmap that guides inspectors through the entire inspection process.

Step 2 – On-Site Inspection Procedures

The on-site inspection procedures are the heartbeat of material inspection. Skilled inspectors follow detailed protocols that include random sampling of materials, visual inspections for defects or irregularities, and, in some instances, laboratory testing to confirm material properties. This hands-on approach ensures that every material used in construction is subject to rigorous scrutiny.

Step 3 – Documentation and Reporting

The importance of accurate documentation cannot be overstated. Inspectors diligently record their findings, creating comprehensive reports that serve as a historical record of the inspection process. These reports include inspection dates, examined materials, test results, and corrective actions taken. This meticulous documentation is invaluable for transparency, traceability, and future reference.

Challenges in Material Inspection

Having said that, you are likely to experience the following challenges during material checks:

1. Quality Assurance

Maintaining a high standard of quality is an ongoing challenge in material inspection. It demands robust quality assurance processes, including regular audits, stringent testing, and continuous monitoring. The objective is to detect and address substandard materials before they jeopardize the structural integrity of the construction project.

2. Time Constraints

Construction projects often operate within tight schedules, and balancing the need for thorough inspection with the demand for timely project completion requires a delicate dance. Meticulous planning and coordination are essential to ensure comprehensive inspections without causing undue delays.

3. Regulatory Compliance

The construction industry operates in a dynamic regulatory landscape. Staying abreast of constantly evolving regulations and standards is a challenge that demands proactive engagement. Construction projects must remain adaptable, requiring continuous education and awareness to avoid delays and legal repercussions.

Technology in Material Inspection

Drones, AR, IoT, and mobile apps such as FAT FINGER are revolutionizing the construction industry. Let’s look at how these technologies contribute to material inspection.

Augmented Reality (AR)

Augmented Reality (AR) is entrenched in construction, from project planning to execution and management. AR integrates digital information and 3D models into the real-world environment on construction sites, providing on-site personnel with an immersive and interactive experience.

Workers equipped with AR devices can access vital data, such as blueprints or safety guidelines, hands-free, fostering safer working conditions and reducing the likelihood of errors.

This technology accelerates decision-making processes and contributes to a more collaborative and informed construction ecosystem, ultimately leading to improved project outcomes.

Use of Drones

The integration of drones in material inspection has transformed the inspection landscape. With high-resolution cameras and sensors, drones provide a bird’s-eye view of construction sites, enabling inspectors to assess materials in challenging or inaccessible locations. This technology enhances both the efficiency and scope of material inspections.

IoT in Material Monitoring

The Internet of Things (IoT) has ushered in a new era of continuous material monitoring. IoT devices embedded in construction materials continuously collect and transmit temperature, humidity, and structural integrity data. This real-time monitoring provides invaluable insights into the health of construction materials, allowing for proactive intervention when needed.

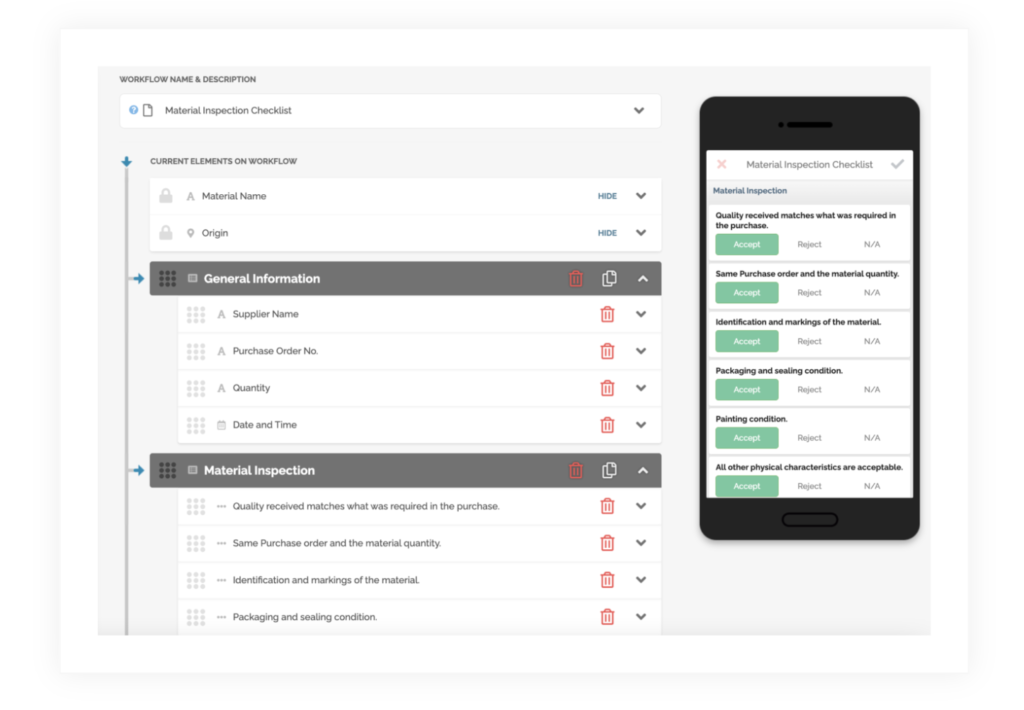

Mobile Apps

FAT FINGER has become indispensable in material inspection by allowing you to create customized digital procedures, workflows and checklists that enable real-time data collection, photo documentation, and instant reporting. This not only streamlines the inspection workflow but also enhances the accuracy and speed of the entire process.

More so, FAT FINGER integrates with all your other technologies, including AR and IoT.

Benefits of Effective Material Inspection

So far, we have covered what material inspection entails, how to conduct one, material inspected, challenges arising during inspection, and the role of technology in this process.

But why conduct material inspection? What are the benefits to your company? More on this below:

Improved Site Safety

One of the primary benefits of effective material inspection is the substantial improvement in site safety. Identifying and rectifying potential hazards before they escalate ensures a secure working environment for all personnel involved in the construction project. This proactive approach reduces the likelihood of accidents and injuries.

Cost Savings

Early detection of substandard materials or defects can result in significant cost savings. Construction projects can adhere to budgetary constraints and timelines more effectively by preventing rework and avoiding delays. The financial benefits of effective material inspection extend beyond immediate savings to the long-term durability of the project.

Enhanced Project Durability

Using high-quality materials, as ensured by effective inspection processes, contributes to the longevity and durability of the construction project.

This is not merely a matter of aesthetics but a fundamental aspect of the project’s overall sustainability. Reduced maintenance needs and increased resistance to wear and tear extend the structure’s lifespan.

Benchmarking

Successful material inspection cases provide a benchmark for conducting similar exercises in the future.

Lessons Learned from Failures

Just like benchmarking, analyzing failures resulting from inadequate material inspection is an essential exercise. Construction professionals can learn valuable lessons by examining cases where material inspections fell short. These lessons enhance their understanding of potential pitfalls, reinforce the importance of adherence to inspection standards, and contribute to an industry-wide culture of continuous improvement.

Digitizing Material Inspection in Construction with FAT FINGER

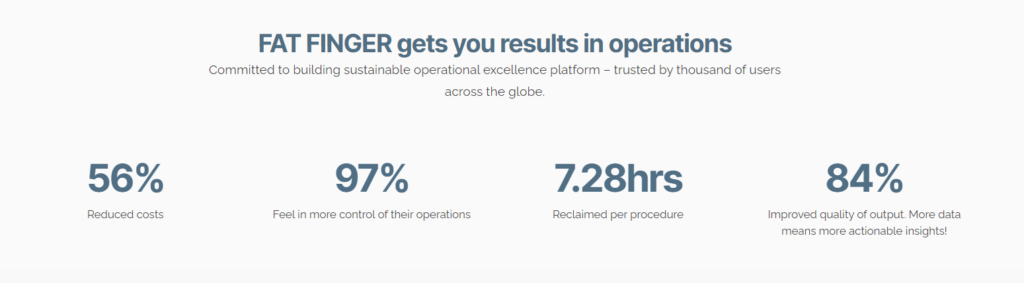

Digitizing material inspection with FAT FINGER goes beyond efficiency; it revolutionizes the entire construction process. The benefits are profound, from streamlined data collection to real-time reporting, enhanced collaboration, improved accuracy, and increased accountability.

I. Streamlined Data Collection

In the conventional approach to material inspection, data collection is often a time-consuming and error-prone task. Paper-based forms, manual recording, and subsequent data entry into digital systems can lead to inaccuracies, delays, and a lack of real-time insights.

Digitizing material inspection with FAT FINGER streamlines data collection by providing a user-friendly mobile application.

Workers or inspectors can input data directly into the system, eliminating the need for manual transcriptions, to accelerate the process, minimize the risk of errors, and ensure accurate and up-to-date information.

II. Real-Time Reporting

Traditional material inspection processes rely on post-inspection reporting, often delaying inspection completion and data dissemination. This delay can hinder prompt decision-making and responsiveness to emerging issues.

FAT FINGER enables real-time reporting by allowing inspectors to input data directly into the system during inspections. This immediate data availability empowers project managers and stakeholders with timely insights, facilitating quick responses to potential issues and fostering a more agile and responsive construction environment.

III. Enhanced Collaboration

Collaboration among project stakeholders in traditional material inspection processes can be challenging. Physical paperwork, delayed reporting, and a lack of centralized information often impede effective communication between on-site inspectors, project managers, and key players.

FAT FINGER promotes enhanced collaboration by centralizing inspection data in a digital platform accessible to all relevant parties. Project stakeholders can collaborate in real-time, share insights, and promptly address issues, improving communication and fostering a collaborative and informed decision-making environment.

IV. Improved Accuracy

Manual data entry and paper-based systems are susceptible to errors. Misinterpretations, illegible handwriting, and data entry mistakes can compromise the accuracy of material inspection records.

FAT FINGER mitigates the risk of errors by providing a digital platform with intuitive interfaces. The standardized data entry process minimizes inconsistencies and records inspection data accurately. This improved accuracy has a ripple effect, contributing to the overall reliability of the material inspection process.

V. Efficient Audit Trails

Creating comprehensive audit trails in traditional material inspection processes can be challenging. The manual nature of data collection and reporting makes it difficult to trace the sequence of events and changes throughout the inspection lifecycle.

FAT FINGER automates the creation of efficient audit trails by recording every action and data entry in the system. This detailed trail enhances transparency and serves as a valuable tool during audits or quality assurance processes.

It provides a comprehensive record of the entire material inspection journey.

VI. Customization for Unique Needs

Traditional material inspection processes often involve standardized forms that may not cater to the specific needs of different projects or materials. Adapting to unique requirements with such rigid processes can take time and effort.

FAT FINGER offers customization options that empower companies to tailor material inspection forms to their needs. Whether it’s adapting to different construction materials, project types, or regulatory requirements, the flexibility of FAT FINGER ensures that the digitized inspection process aligns seamlessly with the unique demands of each project.

VII. Increased Accountability

Assigning accountability in traditional material inspection processes can be challenging due to the decentralized nature of data collection and reporting. It’s often difficult to pinpoint responsibility for oversights or issues.

FAT FINGER enhances accountability by providing a clear digital trail of each inspector’s actions. With individual user profiles and timestamps, companies can easily trace who performed each inspection, what changes were made, and when. This increased accountability fosters a culture of responsibility and diligence among inspection teams.

VIII. Integration with Existing Systems

Traditional material inspection processes may exist in silos, separate from other project management or enterprise resource planning (ERP) systems. Integration challenges can hinder seamless collaboration between different facets of construction management.

FAT FINGER facilitates integration with existing systems, allowing seamless data flow between material inspection processes and other construction management tools. This integration streamlines workflows, reduces duplication of efforts, and ensures a holistic approach to project management.

IX. Enhanced Training and Onboarding

Training new inspectors in traditional material inspection processes can be time-consuming and challenging. The reliance on manual processes may result in a steep learning curve for newcomers.

FAT FINGER’s AI coach simplifies training and onboarding by providing relevant on-the-job advice to boost performance. Additionally, FAT FINGER’s intuitive and user-friendly interface makes it easy for new inspectors to quickly adapt to the digital platform, reducing the time required for training and enhancing the overall efficiency of the inspection team.

Are you ready to optimize material inspection workflows and lay the foundation for a more agile, responsive, and digitally empowered construction process?