As the world continues to grapple with the need for clean and sustainable energy, nuclear power remains a significant part of the energy mix. However, with many nuclear facilities aging, the challenge of maintenance becomes increasingly critical. This article explores the maintenance challenges in aging nuclear facilities and how innovative solutions like FAT FINGER can help address these issues.

The Aging Nuclear Infrastructure

Many nuclear facilities worldwide are reaching or have surpassed their initial design life. This aging infrastructure presents a unique set of challenges, particularly in the area of maintenance.

- Increased Risk of Component Failure: As facilities age, the risk of component failure increases. This can lead to unplanned shutdowns, affecting the reliability of power supply.

- Regulatory Compliance: Aging facilities must meet stringent safety and environmental regulations, which often require costly upgrades or modifications.

- Workforce Challenges: The nuclear industry faces a shortage of skilled workers, particularly those with experience in operating and maintaining older facilities.

- Costs: The cost of maintaining an aging facility can be high, particularly when it comes to replacing or repairing aging equipment.

How FAT FINGER Can Help

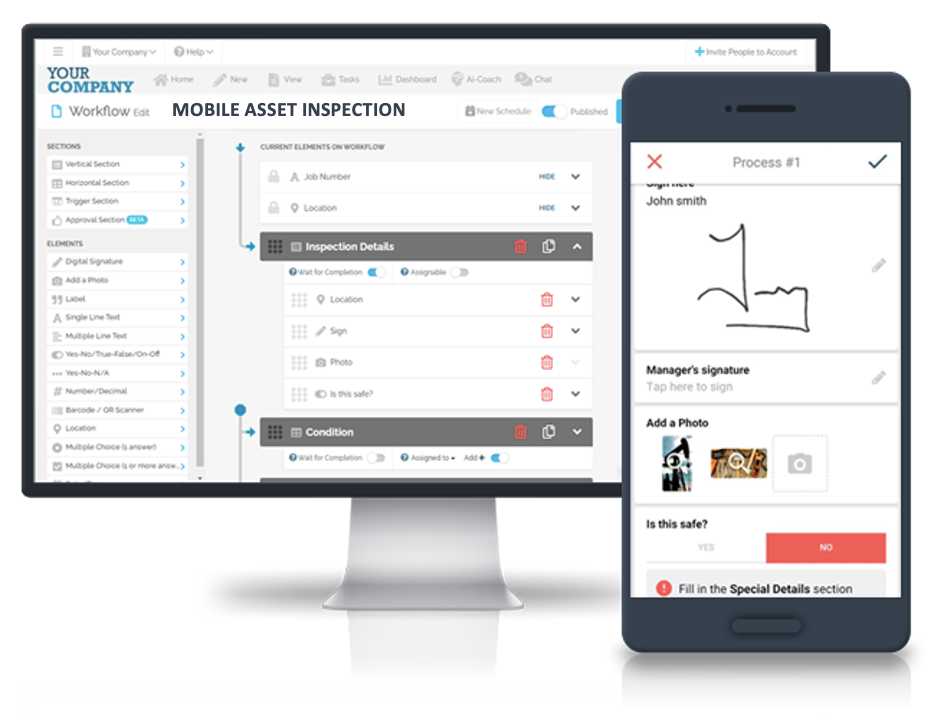

FAT FINGER, a digital workflow procedure builder, can empower front-line teams to do their work correctly every time. It allows you to build checklists, workflows, and digital procedures that unlock operational excellence. This can be particularly beneficial in the context of maintaining aging nuclear facilities.

- Work Order Checklist: FAT FINGER’s Work Order Checklist can help ensure that maintenance tasks are performed correctly and consistently, reducing the risk of component failure.

- Mobile Asset Inspection: With FAT FINGER, teams can conduct mobile asset inspections, allowing for real-time data collection and analysis. This can help identify potential issues before they lead to failures.

- Preventive Maintenance Inspection: FAT FINGER’s Preventive Maintenance Inspection feature can help facilities stay ahead of potential issues, reducing the need for costly repairs or replacements.

- Predictive Maintenance: By integrating with IoT devices, FAT FINGER can enable predictive maintenance, identifying potential issues before they become problems.

Conclusion

Maintaining aging nuclear facilities is a complex and challenging task. However, with the right tools and strategies, it is possible to manage these challenges effectively. Solutions like FAT FINGER can play a crucial role in this process, providing the tools needed to ensure consistent, reliable, and efficient maintenance practices. By leveraging digital workflows and checklists, facilities can improve their maintenance practices, reduce the risk of component failure, and ultimately extend the life of their aging infrastructure.

Ready to see how FAT FINGER can help your facility overcome its maintenance challenges? Sign up for a free trial or request a demo today.