Amidst the myriad of regulations set forth by the Occupational Safety and Health Administration (OSHA), one topic stands out: fall protection. Falls are among the most common causes of occupational injuries, regardless of the industry. These accidents can lead to disabilities or, in the worst-case scenario, fatalities.

Recognizing this, OSHA has taken it upon itself to develop stringent regulations to mitigate the risk of falls.

In this article, we’ll explore OSHA’s regulations for safety harnesses. We’ll also discuss how you can use FAT FINGER to mitigate the risk of falls and be compliant with OSHA.

Types of Fall Protection Harnesses

Fall protection harnesses, often called “safety harnesses,” are specialized safety equipment designed to arrest falls and protect workers from injuries.

- Several types of fall protection harnesses are available, each suited to different working conditions. These may include, Construction harnesses

- Full-body harnesses

- Suspension trauma relief harnesses

Selecting the right type depends on the specific requirements of the job at hand.

Components of a Safety Harness

Understanding the components of a fall protection harness is essential for safe usage. A standard harness typically consists of webbing, D-rings, buckles, and other hardware that secures the worker to a lifeline or anchor point.

While the components may vary depending on the type of harness, they all serve the same primary purpose: to keep the worker safe in the event of a fall.

OSHA Regulations for Fall Protection Harnesses

OSHA has established strict requirements for the use of fall protection harnesses. These requirements encompass various aspects, including ensuring that harnesses meet industry standards and are inspected before each use.

As an employer, you are obligated to provide and ensure the use of harnesses, along with other fall protection equipment, when necessary.

Inspections and Maintenance

It is mandatory to conduct regular inspections to identify any wear and tear on harnesses. If you notice any damaged harnesses, you must replace them with new one.

Proper maintenance ensures that harnesses remain in good working condition, ready always to protect workers.

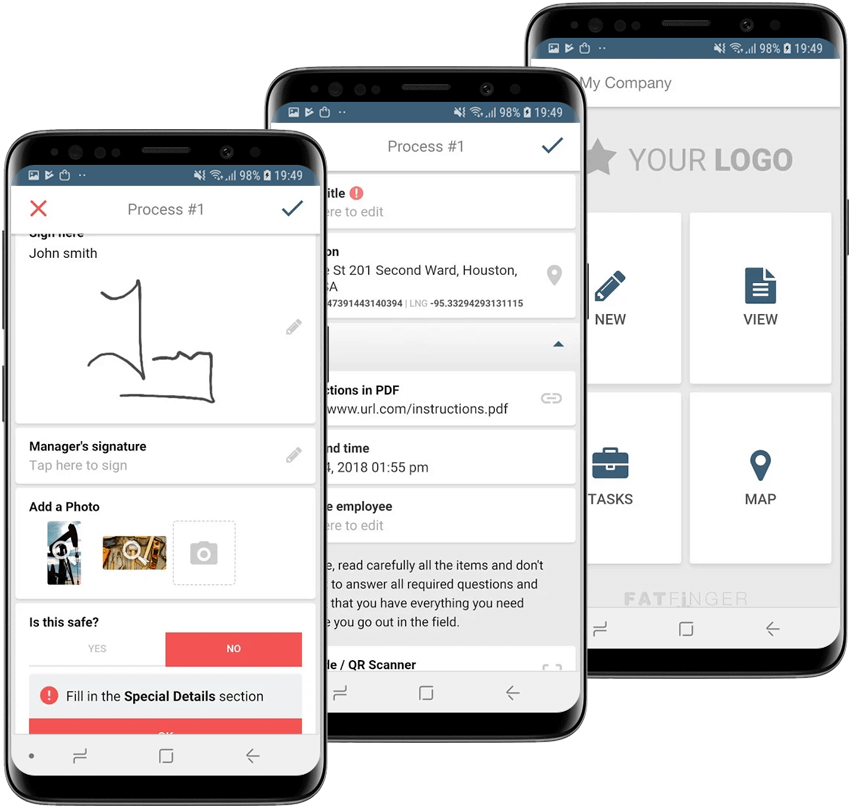

Equipment inspection should be thorough. One way to ensure thoroughness is by digitizing safety management with FAT FINGER, a no-code, easy-to-use, safety workflow builder.

For example, you can build a Take 5 safety checklist for your safety harnesses to ensure workers inspect them before work.

Training and Certification

Another critical facet of OSHA’s fall protection regulations is the training and certification of employees who use fall protection harnesses.

Proper training ensures that workers understand how to use the harness correctly, fit it properly, and are aware of potential fall hazards in the workplace. Certification serves as proof of competence in the safe use of harnesses.

Choose the Right Safety Harness for the Job

Selecting the proper harness depends on the specific hazards present in the workplace. Before choosing a harness, you should conduct a thorough hazard assessment. The right harness should consider:

- The nature of the work

- The potential for falls

- Type of anchor points available

The Cost of Non-compliance With OSHA Regulations

Non-compliance with OSHA regulations regarding fall protection harnesses can lead to severe consequences for employers and employees.

Fines, injuries, and even fatalities can occur when these regulations are not followed.

The monetary penalties for non-compliance can be substantial and vary depending on the severity of the violation.

Tips for Ensuring Compliance

Ensuring compliance with OSHA regulations is not just about avoiding fines—it’s about creating a safer work environment and saving lives.

Employers and employees can take several steps to maintain compliance:

- Regularly inspect harnesses for wear and tear.

- Provide and require training for all workers who use fall protection harnesses.

- Ensure that workers are certified in the safe use of harnesses.

- Conduct thorough hazard assessments before starting any job. You can use our premade Take Five template, or create your own in minutes.

- Invest in the appropriate type of harness for the job.

- Always replace damaged harnesses promptly.

Conduct take-5 Inspection on Safety Harnesses with FAT FINGER

OSHA regulations for fall protection harnesses are not to be taken lightly. FAT FINGER equips you with the necessary tools to make adhering to these regulations prioritizing easy. For example, you can:

- Anticipate and prevent risk with JHA/JSA workflows

- Enhance safety with quick incident reports

Besides promoting workplace safety, FAT FINGER is widely applicable across different industries, serving companies to:

- Boost operational productivity through quality control checks

- Protect and improve asset reliability with adequate maintenance checks

With FAT FINGER, you can solves the problems posed by manual processes pose such as:

- Low throughput due to the time-consuming and repetitive nature of manual work

- High operational costs owing to the number of resources used

- Limited visibility to data due to decentralized data sources