Line clearance, or line changeover, is a critical process in manufacturing that ensures the seamless transition between different production processes. It involves verifying that all line changeover activities have been completed and that the line is ready to resume production. The benefits of line clearance include reduced downtime, improved line efficiency, and increased product quality. However, this process can be complex and prone to errors if not managed correctly.

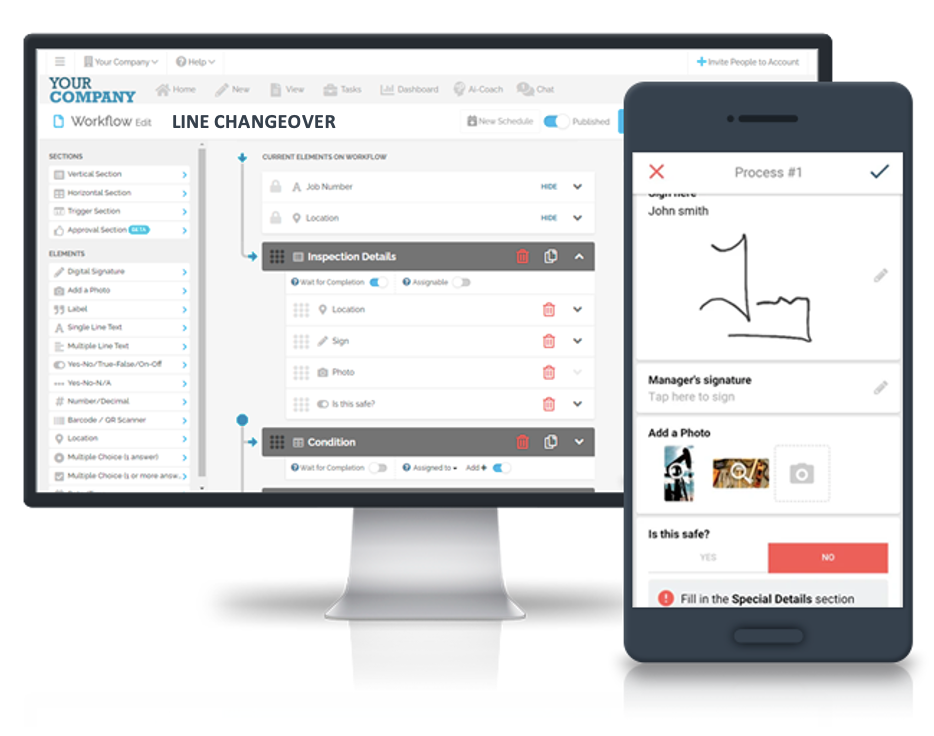

This is where FAT FINGER comes in. FAT FINGER is a digital workflow procedure builder that empowers front-line teams to do their work correctly every time. With FAT FINGER, you can build digital workflow procedures to facilitate seamless line changeovers.

Request a demo to see how FAT FINGER can revolutionize your line clearance process.

Why is Line Clearance Important?

Shop floors are constantly changing; manufacturers must introduce new products, discontinue old ones, adjust production schedules, and more. With so many moving parts, line changeovers must be managed carefully to avoid disruptions in production. By verifying that all necessary line changeover activities have been completed, line clearance helps to ensure a smooth, efficient manufacturing process.

How FAT FINGER Streamlines Line Clearance

Production Managers have praised FAT FINGER for its ability to streamline the line clearance process. One manager stated, “FAT FINGER is a game changer for our production line clearance process. We can now streamline our production lines with confidence knowing that everything is right at our fingertips.”

3 Steps Involved During Line Clearance Procedures:

- Clearing the line involves removing all products from the line and ensuring that no product remains in any of the line equipment. This step is essential to prevent cross-contamination of products.

- Cleaning the line involves sanitizing all surfaces that will come into contact with the product. This step is essential to prevent bacteria from contaminating products. It also involves removing all product build-up and debris from the line.

- Inspection is conducted to ensure that the line is clear and clean and that all equipment is in good working order. All moving parts should be lubricated, and all electrical connections should be secure. After inspection, the line is restarted, and production can resume.

The Power of a Digital Line Clearance Checklist

In modern manufacturing, line clearance is an essential part of quality control. By using a digital Line Clearance Checklist, manufacturers can streamline the process and reduce the chances of human error. A CXV Global survey of 30 pharmaceutical professionals found that 100% of respondents had experienced a line clearance error in the past year, and 96% said their current line clearance process takes more than 60 minutes.

Benefits of Using FAT FINGER for Line Clearance

- With FAT FINGER, all the necessary information is stored in one place, and anyone on the production line can quickly access it.

- Remarks, corrective actions, and photos collected during line clearance can be added to the workflow.

- Generate reports on-site and send them to relevant stakeholders via email, PDF, or web link. This way, everyone can stay up-to-date on the latest information.

- Assign tasks and schedule your clearance line inspection directly from the app. This ensures everyone is on the same page and no one misses a beat.

Conclusion

Line clearance is a critical process in manufacturing that ensures the seamless transition between different production processes. With FAT FINGER, you can streamline this process, reduce errors, and ensure that your production line is ready to resume production at all times.

Don’t wait, sign up to create a line changeover workflow for free on FAT FINGER or schedule a demo today!

Ready to ensure thorough preparation with our Comprehensive Line Clearance Checklist? Don’t miss out on this opportunity to streamline your operations and enhance safety. Schedule a demo today and experience the difference.