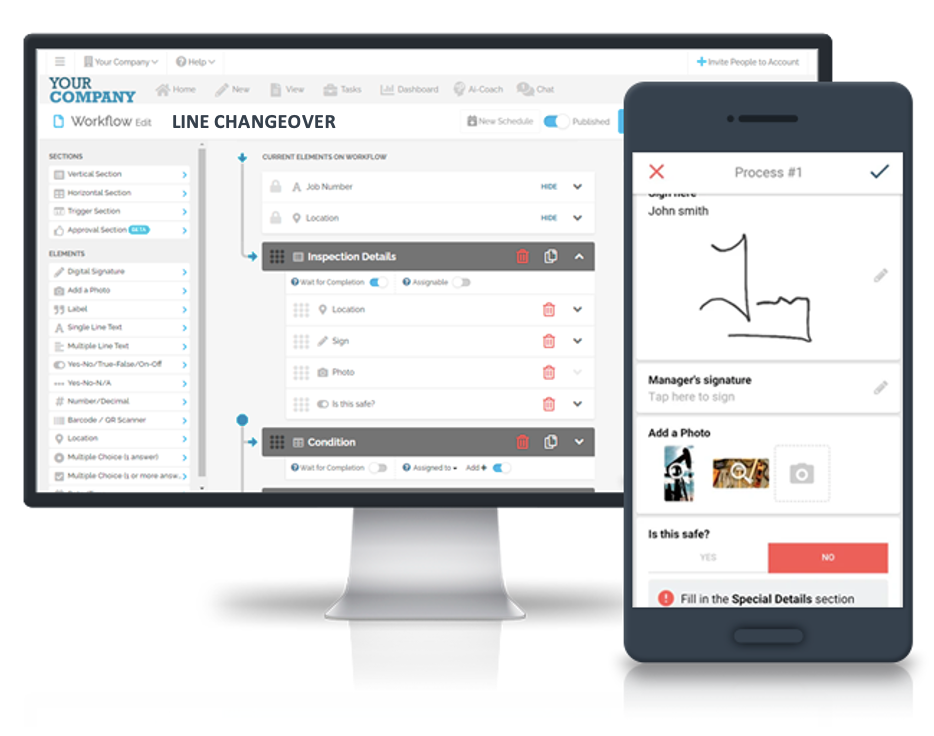

Manufacturing processes are complex and require meticulous attention to detail. One such critical process is line clearance, which ensures that production lines are ready for a seamless transition between different products or processes. This is where FAT FINGER comes into play. FAT FINGER is a digital workflow procedure builder that empowers front-line teams to do their work correctly every time. With FAT FINGER, you can build digital workflow procedures to facilitate seamless line changeovers, reducing downtime, improving line efficiency, and increasing product quality.

Understanding Line Clearance Procedures

Line clearance, also known as line changeover, is the process of verifying that all line changeover activities have been completed and that the line is ready to resume production. This process is crucial in preventing disruptions in production and ensuring a smooth, efficient manufacturing process.

Steps Involved During Line Clearance Procedures

- Clearing the line: This involves removing all products from the line and ensuring that no product remains in any of the line equipment. This step is essential to prevent cross-contamination of products.

- Cleaning the line: This involves sanitizing all surfaces that will come into contact with the product. This step is essential to prevent bacteria from contaminating products. It also involves removing all product build-up and debris from the line.

- Inspection: This is conducted to ensure that the line is clear and clean and that all equipment is in good working order. All moving parts should be lubricated, and all electrical connections should be secure. After inspection, the line is restarted, and production can resume.

The Role of FAT FINGER in Line Clearance Procedures

FAT FINGER is a game changer for line clearance procedures. It allows manufacturers to streamline their production lines with confidence, knowing that everything is right at their fingertips. With FAT FINGER, all the necessary information is stored in one place, and anyone on the production line can quickly access it.

Benefits of Using FAT FINGER for Line Clearance

- Remarks, corrective actions, and photos collected during line clearance can be added to the workflow.

- Generate reports on-site and send them to relevant stakeholders via email, PDF, or web link. This way, everyone can stay up-to-date on the latest information.

- Assign tasks and schedule your clearance line inspection directly from the app. This ensures everyone is on the same page and no one misses a beat.

Conclusion

Line clearance procedures are essential to ensure a safe and efficient manufacturing process. By following these steps, manufacturers can prevent contamination and ensure quality products. With FAT FINGER, you can make your line changeover as smooth as possible.

Clear your production line with confidence, knowing that you have everything you need right at your fingertips. So why wait? Sign up to create a line changeover workflow for free on FAT FINGER or schedule a demo today!

Don’t compromise on compliance and safety in your GMP Line Clearance Procedures. Learn more about our solutions and ensure your operations are up to standard. Schedule a demo today to see how we can help.